Anionic lipophilic glycerol-based polymers for organic deposition control in papermaking processes

An anionic, paper-making technology, applied in the fields of inorganic compound addition, papermaking, textiles and papermaking, etc., can solve problems such as reducing paper quality and reducing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

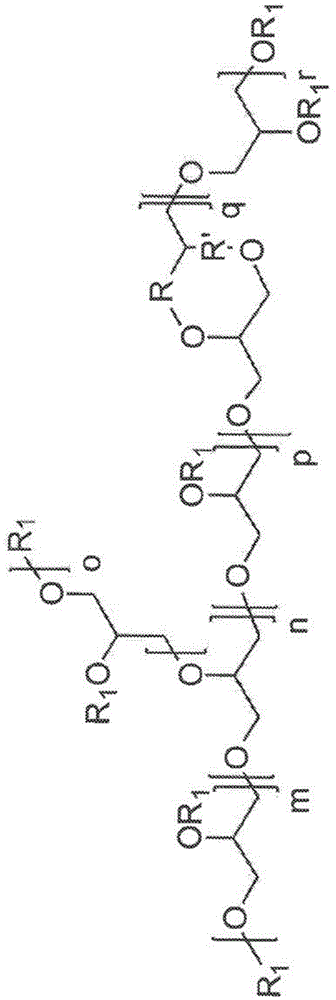

[0067] Embodiment 1: the synthesis of polyglycerol

[0068] 100 units (or use a different amount) of glycerol was added to the reaction vessel, followed by 3.0% to 4.0% active NaOH relative to the reaction mixture. This mixture is agitated under a specific low reactivity atmosphere at a nitrogen flow rate of 0.2 mol to 4 mol nitrogen per hour per mole of monomer and then gradually heated up to 240°C. This temperature is maintained for at least three hours to achieve the desired polyglycerol composition when agitated in a specific low reactivity atmosphere. In-process polyglycerol samples were taken for molecular weight / composition analysis / property testing prior to the next step. For performance testing, polyglycerol was dissolved in water as a 50% product. The analysis of polyglycerol (PG) is summarized in Table 1.

[0069] Table 1: Polyglycerol Composition

[0070] Polyglycerol

Embodiment 2

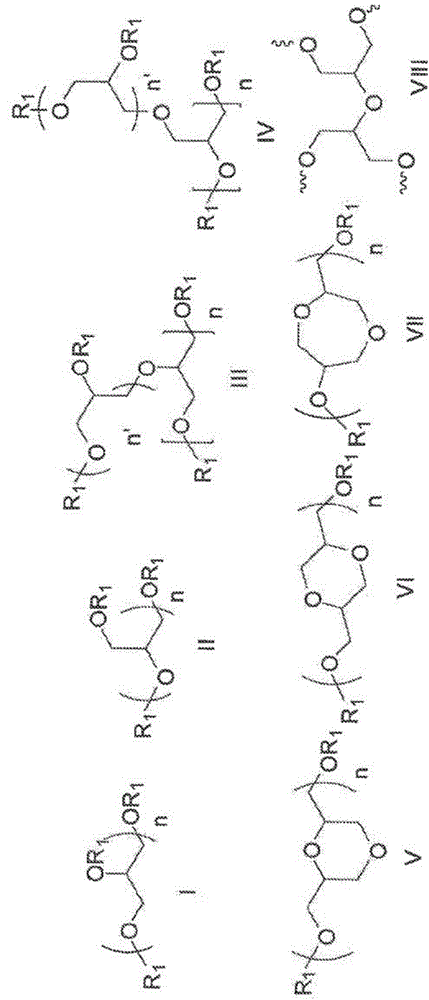

[0071] Embodiment 2: the synthesis of anionic lipophilic polyglycerol (ALPG)

[0072] To a reaction vessel with 100 units of polyglycerol (PG2) was added polyphosphoric acid (116.2% by weight relative to polyglycerol). The mixture was gradually heated to 130° C. under a nitrogen atmosphere with stirring (as long as stirring was possible) and maintained at this condition for several hours to achieve the desired phosphorylation. After cooling, 1-hexanol (31.9% by weight relative to polyglycerol) was added. The mixture was gradually heated to 150° C. under nitrogen atmosphere with stirring and maintained at this condition for several hours to produce the final composition. ALPG was dissolved in water as a 60% product.

Embodiment 3

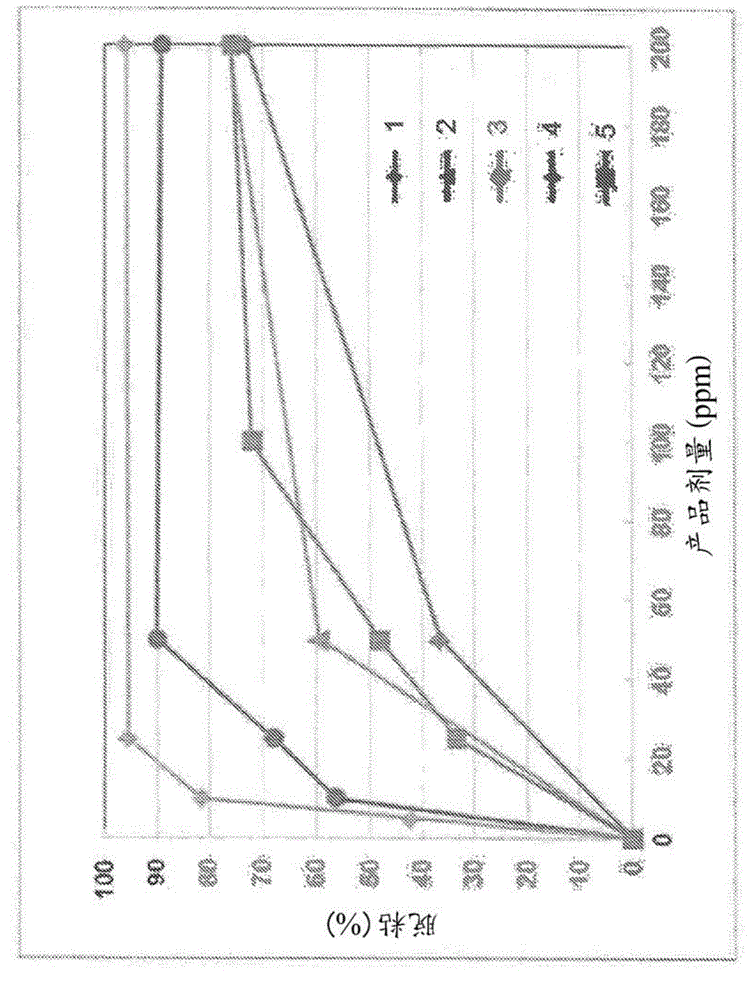

[0073] Embodiment 3: performance test

[0074] For the organic deposition control experiments, a file folding label (TopStick 4282) was used as the adhesive, and the baffle test method was used to assess the chemical effectiveness of the deposited material (compared to that of the blank test).

[0075] Topstick labels (12.4cm x 21.0cm) were placed on plain copy paper and the paper with adhesive was cut or torn into 2.5cm square pieces and placed in the shredder container. Plain copy paper without adhesive was also cut or torn into 2.5 cm square pieces and added to the shredder container to make up a total of 18.75 g of paper material. Hot water was added to the disintegrator vessel to a total weight of 1875 g of the suspension, and the suspension was mechanically comminuted for 30 minutes to produce a pulp of 1% consistency. The pulp was transferred to a baffled test vessel and diluted with 1875 g of hot water followed by mixing to form a pulp for testing at a consistency of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com