Nuclear reactor with liquid metal coolant

A nuclear reactor and liquid metal technology, applied in nuclear reactors, reactors, fast fission reactors, etc., can solve problems such as fast neutron spectrum reactor reaction failures, and achieve the effect of ensuring long-term corrosion resistance and erosion resources, simplifying cooling conditions, and reducing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

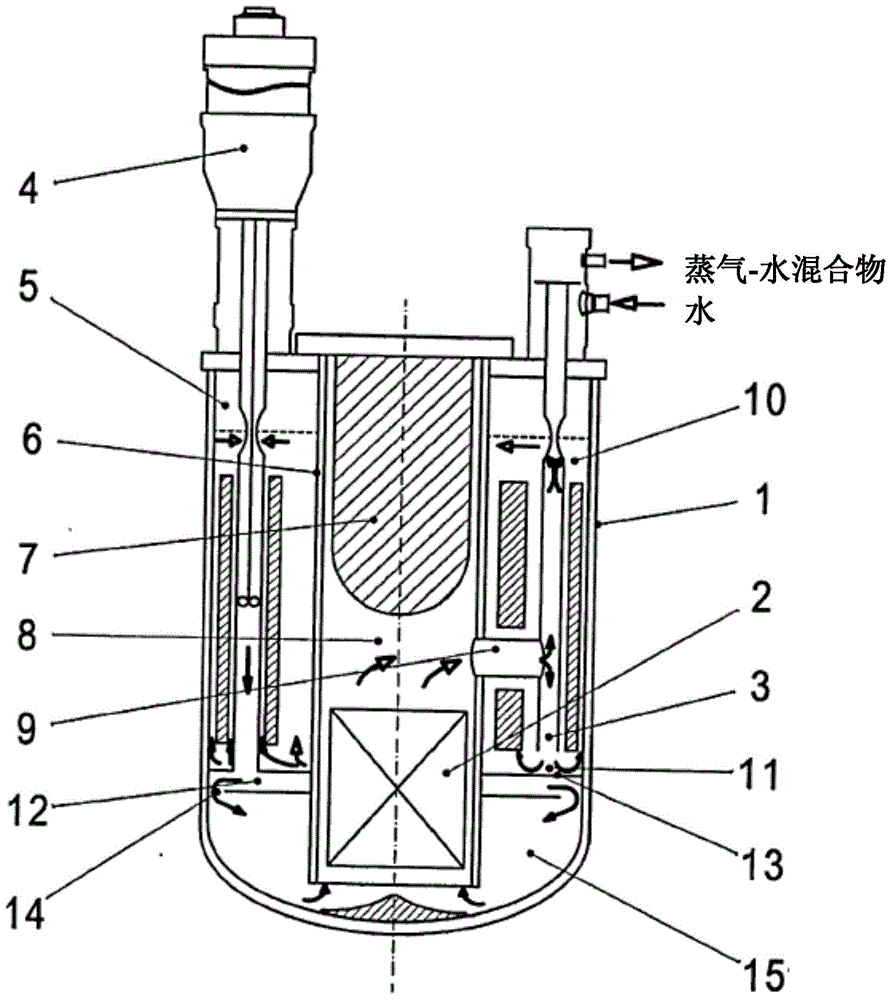

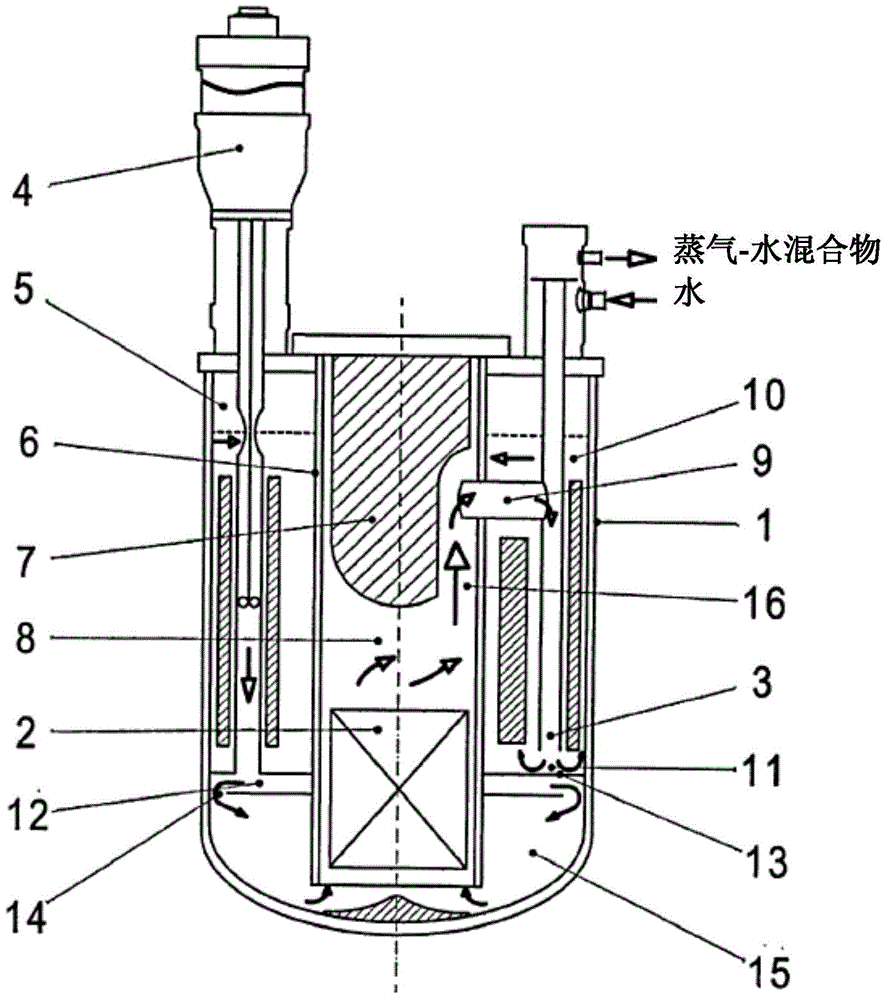

[0033] According to a first embodiment of the invention, the inlet connection is arranged in the middle (height) part of the SG (3).

[0034] After entering the middle part of the SG (3), the hot liquid metal coolant is separated into two parts: the upflow, which cleans the upper part of the SG (3) and flows freely through the formed openings into an upper horizontal cold collector (10) with an underfilled coolant level, said upper horizontal cold collector being disposed in the annular space below the reactor head, between the SG and the casing of the pump; and descending flow, which washes the lower part of the SG (3), enters the lower accumulating collector (11), and flows from said lower accumulating collector (11) as an ascending flow through an annular channel extending along the reactor shell and through The passage formed by the in-housing radiation protection elements arranged between the separating casing, the casing and the casing of the SG and the pump, enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com