Hollow billet inlet pressure adjuster

A technology for importing pressure regulators, applied in horticulture, botany equipment and methods, cultivation and other directions, can solve the problems of large assembly workload, complex structure, many components of pressure regulators, etc., and achieve low cost and pressure regulation effect. Good, improve the effect of irrigation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred implementation method of the present invention will be described in detail below in conjunction with the accompanying drawings.

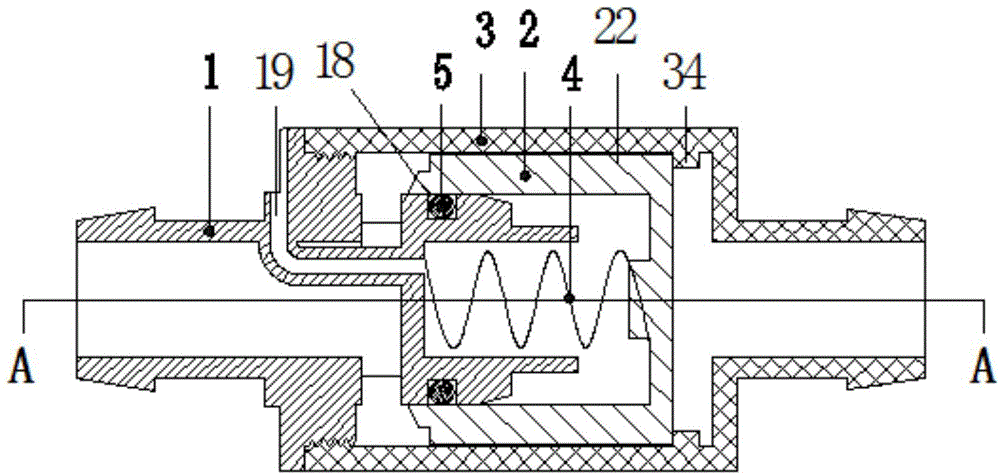

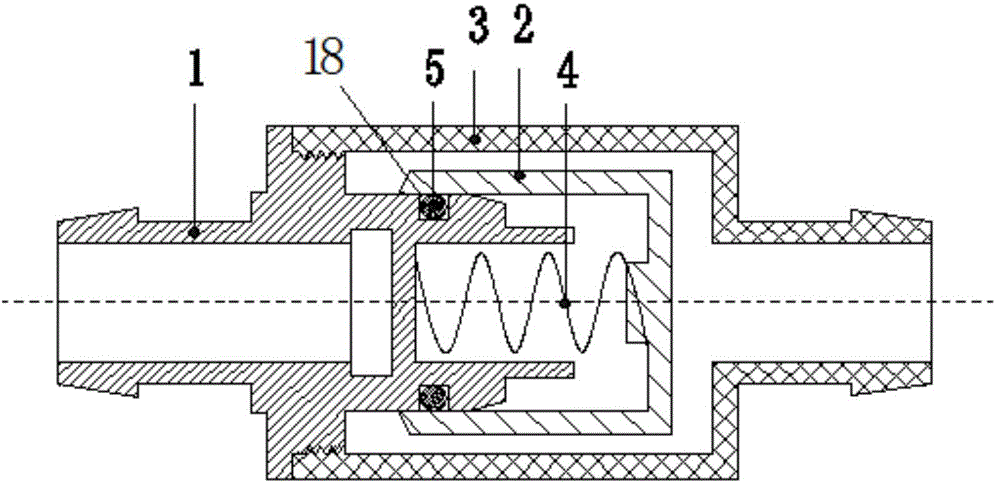

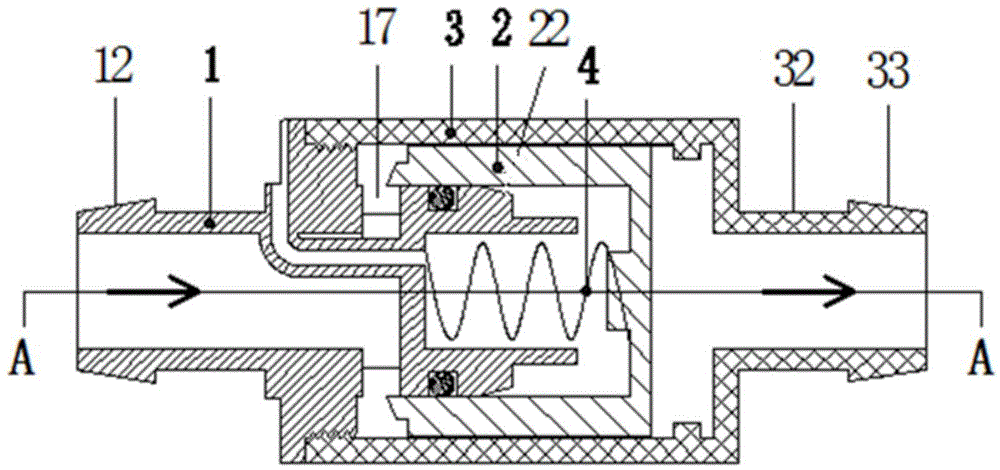

[0023] The present invention adopts the following technical solutions: a capillary inlet pressure regulator, such as figure 1 As shown, the present invention includes an upstream deflector 1 , a pressure regulating assembly 2 , a downstream casing 3 and a spring 4 .

[0024] Such as Image 6 As shown, the upstream diversion body 1 is a tubular structure, and its outer walls have different diameters. The diameter of the central part is larger than the diameters of the two ends. One end is the connection end 13 of the pressure regulating assembly; a barrier 14 is arranged inside the upstream guide body 1 and behind the shell connection end 11, and the barrier 14 divides the interior of the upstream guide body into upper chambers 15 that are not connected to each other and the lower cavity 16; the side wall of the upper cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com