Glyphosate dry suspension and preparation method and application thereof

A dry suspension agent, glyphosate technology, applied in the field of its preparation, glyphosate dry suspension agent, can solve problems such as poor stability and disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a kind of preparation method of glyphosate dry suspension concentrate as described in above-mentioned technical scheme, comprises the following steps:

[0036] mixing glyphosate, wetting agent, dispersant, defoamer, binder, disintegrant, carrier and water to obtain a slurry;

[0037] The slurry is dried and granulated to obtain a glyphosate dry suspension.

[0038] The invention mixes glyphosate, wetting agent, dispersant, defoamer, binding agent, disintegrating agent, carrier and water to obtain slurry.

[0039] In the present invention, the type, dosage and source of the glyphosate, wetting agent, dispersant, defoamer, binding agent, disintegrant and carrier are the same as those of glyphosate, wetting agent described in the above technical scheme , dispersant, defoamer, binder, disintegrant and carrier are the same in type, amount and source, and will not repeat them here.

[0040] In the present invention, the solid content of t...

Embodiment 1

[0074] Embodiment 1 30% glyphosate dry suspension concentrate

[0075] Add 200kg of water, 32kg of glyphosate technical material with a content of 95%, 2kg of sodium lauryl sulfate, 4kg of polycarboxylate, 2kg of sodium lignosulfonate, 0.5kg of organic silicone, and sulfuric acid in a 500L mixing kettle. 5kg of sodium, 5kg of sodium carboxymethylcellulose, 4.8kg of gelatin, and 46.7kg of kaolin were mixed to obtain a slurry;

[0076] The uniformly mixed slurry is sanded by a sand mill until the particle size is qualified, and then the suspoemulsion slurry is pumped into a pressure spray dryer for drying and granulation. The spray pressure is controlled at 4MPa, and the drying gas inlet temperature is 140°C. The air outlet temperature is 75°C, and the granulated material is sieved to obtain 80-120 mesh glyphosate dry suspension concentrate.

Embodiment 1~10

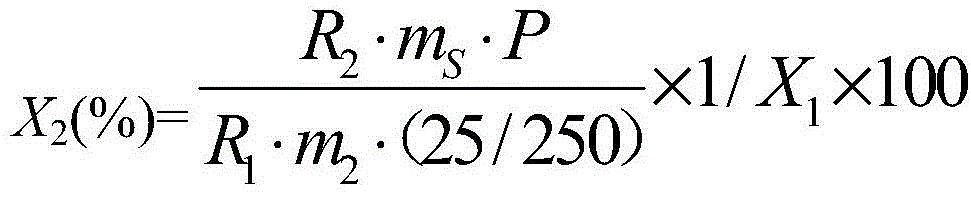

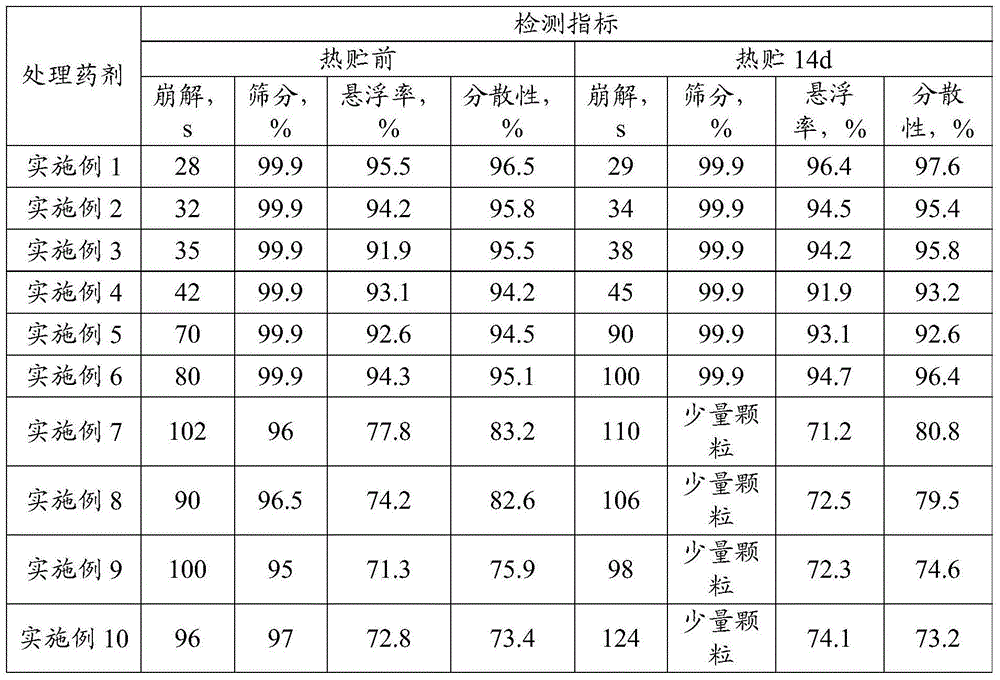

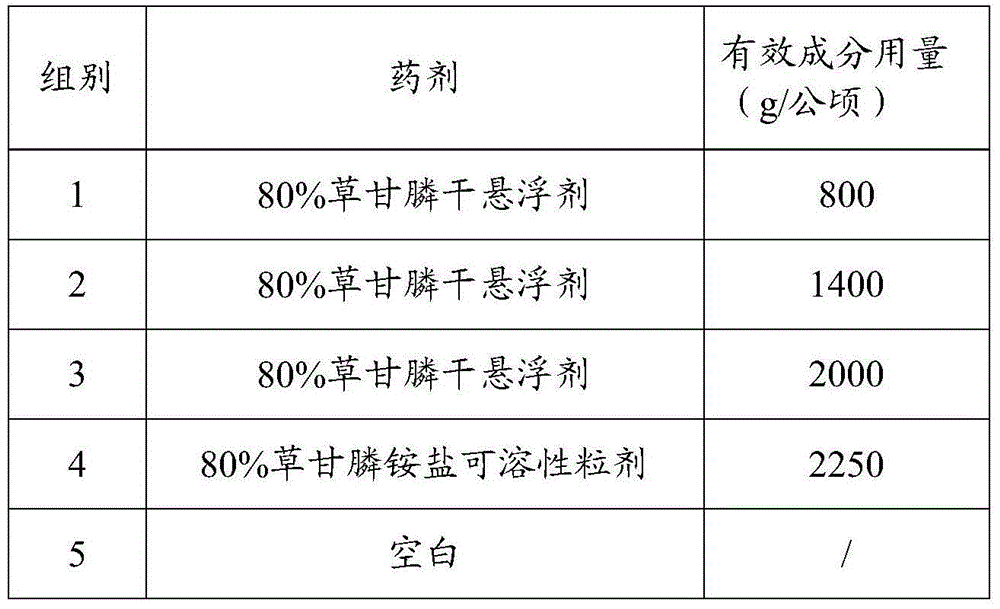

[0077]The present invention adopts the test method described in the above technical scheme to test the disintegration time, suspension rate and sieving of glyphosate dry suspension.

[0078] The performance test results of the prepared glyphosate dry suspension concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com