Two-section evaporation separator

A technology of two-stage evaporation separation and separation zone, which is applied in the field of evaporation system, can solve the problems of occupying synthesis, decomposition, evaporation system capacity, high gas phase entrainment of urea, and affecting product quality, etc., to achieve better control of drainage indicators and improve absorption capacity , The effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

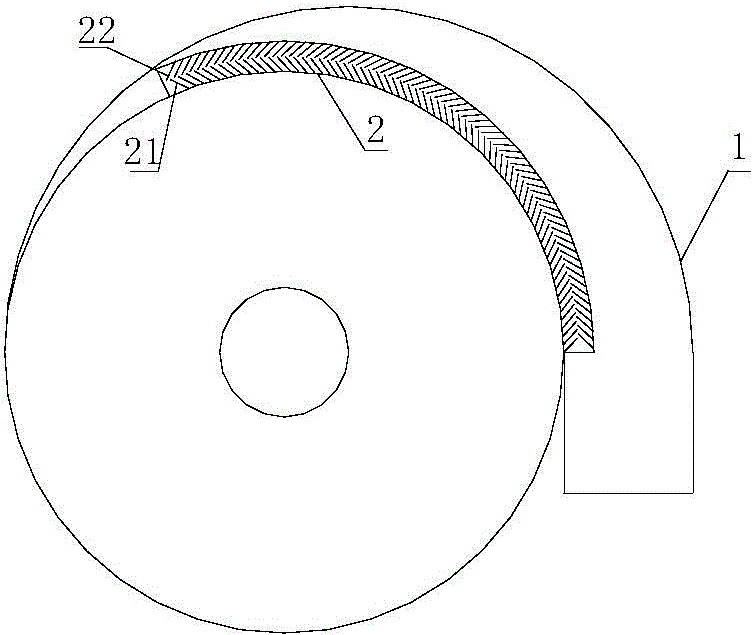

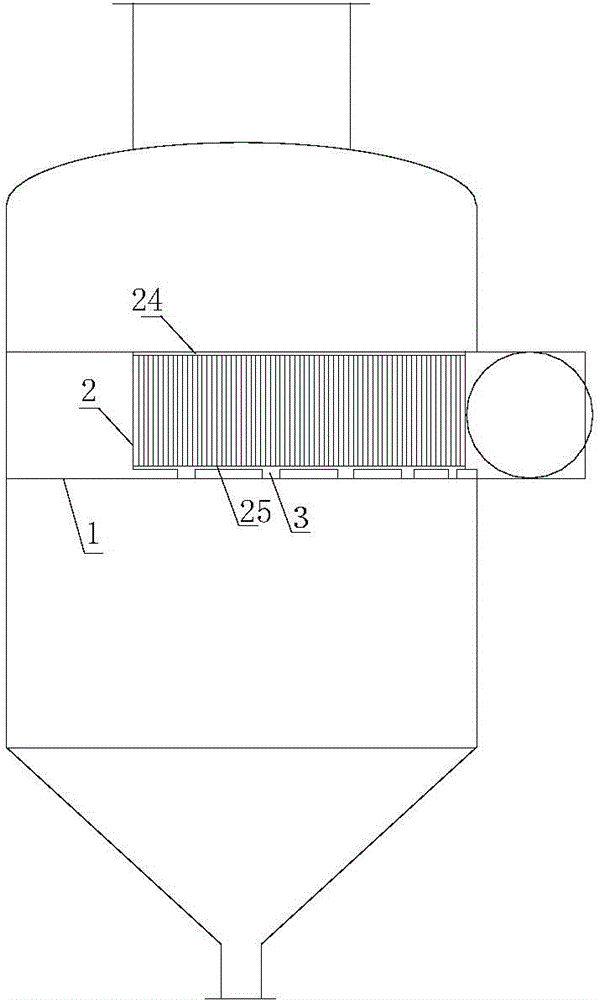

[0029] Second stage evaporative separator, such as Figure 1-3 As shown, including the volute 1, the inner wall of the volute 1 is provided with a mist separation area 2, the angle between the two ends of the mist separation area 2 and the center of the volute 1 is 40-180°, and the mist separation area 2 includes fins , the fins are made of titanium. The lower side of the fins is provided with a first fixed plate 24, and the upper side of the fins is provided with a second fixed plate 25. The fins include a first fin 21 and a second fin 22, between the first fin 21 and the second fin 22 The included angles between them are the same, and the number of the first fins 21 and the second fins 22 are both 45-100.

[0030] A liquid phase diversion area 3 is provided on the lower side of the volute 1, and the liquid phase diversion area 3 is connected with the mist separation area 2, and the number of three liquid phase diversion areas is six. The cross section of the liquid phase d...

Embodiment 2

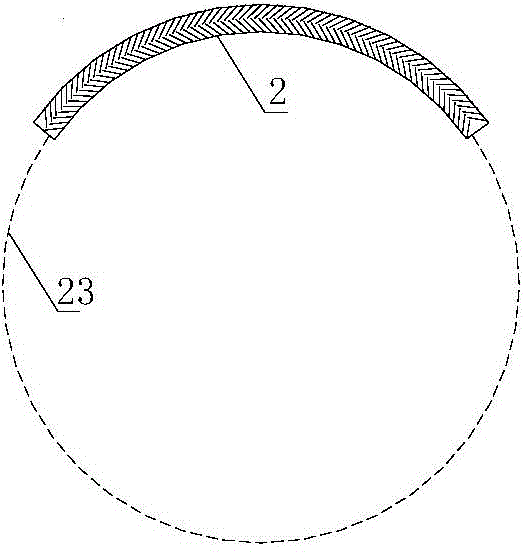

[0032] Second stage evaporative separator, such as Figure 1-3 As shown, including the volute 1, the inner wall of the volute 1 is provided with a mist separation area 2, the angle between the two ends of the mist separation area 2 and the center of the volute 1 is 40-180°, and the mist separation area 2 includes fins , the tangent line between the fin and the circle 23 where the mist separation zone is located is 45°. The lower side of the fins is provided with a first fixed plate 24, and the upper side of the fins is provided with a second fixed plate 25. The fins include a first fin 21 and a second fin 22, between the first fin 21 and the second fin 22 The included angles between them are the same, and the numbers of the first fins 21 and the second fins 22 are the same.

[0033] A liquid phase diversion area 3 is provided on the lower side of the volute 1, and the liquid phase diversion area 3 is connected with the mist separation area 2, and the number of three liquid ph...

Embodiment 3

[0035] Second stage evaporative separator, such as Figure 1-3 As shown, including the volute 1, the inner wall of the volute 1 is provided with a mist separation area 2, the angle between the two ends of the mist separation area 2 and the center of the volute 1 is 40-180°, and the mist separation area 2 includes fins , the tangent line between the fin and the circle 23 where the mist separation zone is located is 45°. The lower side of the fins is provided with a first fixed plate 24, and the upper side of the fins is provided with a second fixed plate 25. The fins include a first fin 21 and a second fin 22, between the first fin 21 and the second fin 22 The included angles between them are the same, and the number of the first fins 21 and the second fins 22 are both 66.

[0036] A liquid phase diversion area 3 is provided on the lower side of the volute 1, and the liquid phase diversion area 3 is connected with the mist separation area 2, and the number of three liquid phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com