Preparation method for micropattern film with selective stimulation recovery function

A micro-pattern and selective technology, applied in the directions of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve the problems of application limitation, non-selectivity of shape recovery parts, etc., to achieve simple preparation process and controllability and selectable and maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific implementation mode 1: This implementation mode is a method for preparing a micropatterned thin film with selective stimulus recovery function, which is specifically carried out according to the following steps:

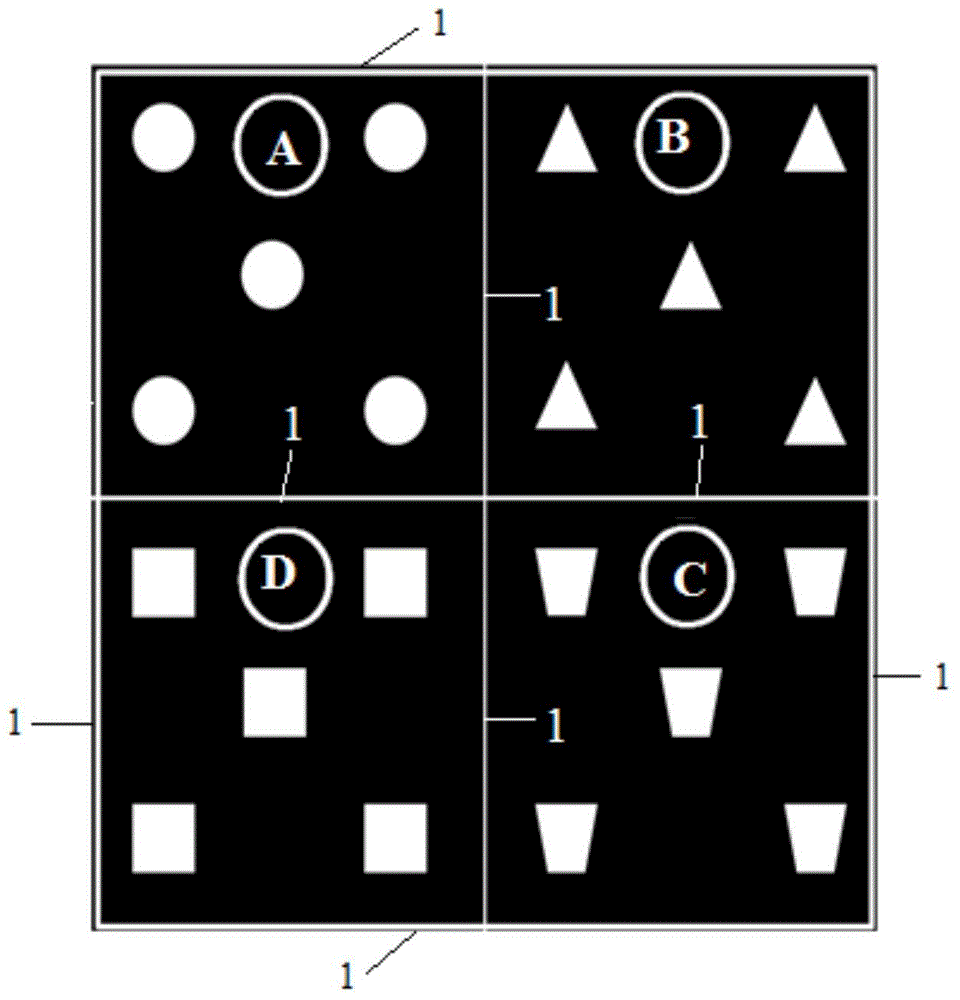

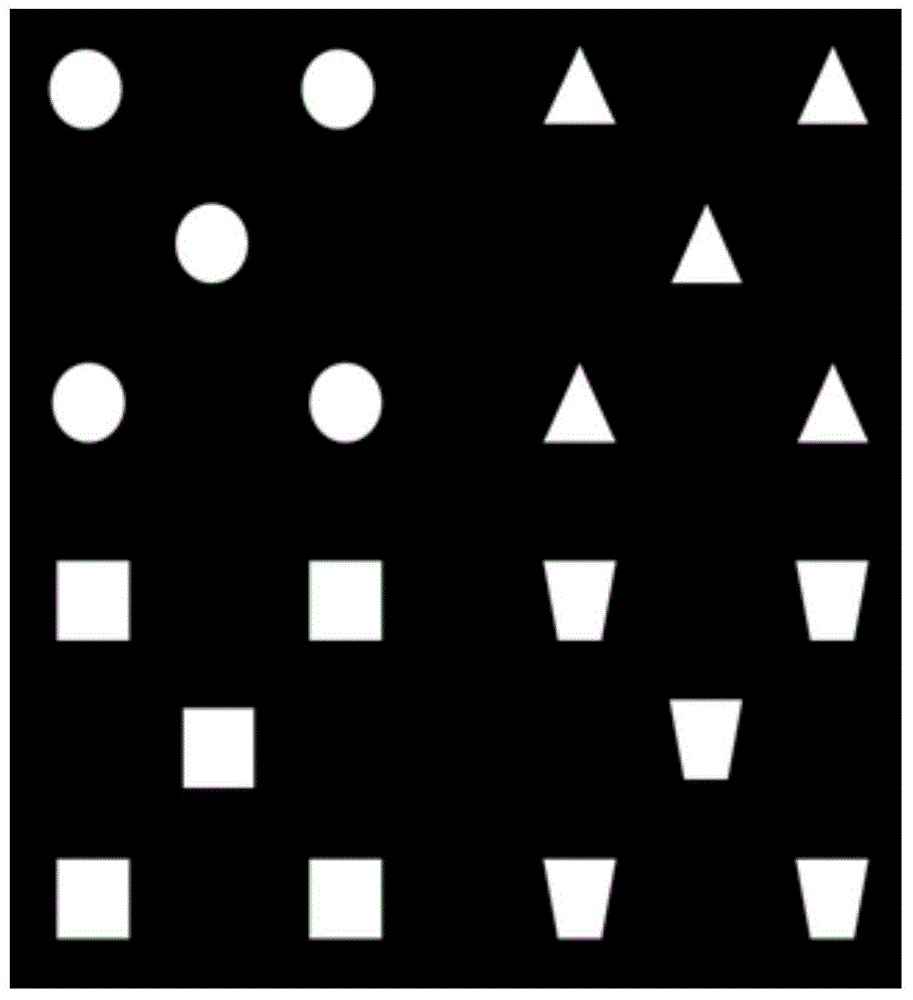

[0017] 1. Isolation of silicon wafers: four rectangular silicon wafers with micropatterns on the surface are glued horizontally on the same glass sheet with 502 glue, and the four silicon wafers with micropatterns on the surface are closely adjacent to form a rectangle I, and then use poly The tetrafluoroethylene film separates four closely adjacent rectangular silicon wafers with micropatterns on the surface from each other and also surrounds the surrounding area of rectangle I. For the four rectangular silicon wafers with micropatterns on the surface of rectangle I, proceed clockwise The directions are respectively set as silicon wafer 1, silicon wafer 2, silicon wafer 3 and silicon wafer 4; the length×width×thickness of the four rectangular silico...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the shape memory polymer described in step 2 is styrene solution or epoxy resin. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the viscosity of the styrene solution at room temperature is 583.3 cP. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com