Preparation method of graphite phase carbon nitride/molybdenum sulfide composite material

A technology of graphite phase carbon nitride and composite materials, which is applied in the field of preparation of graphite phase carbon nitride/molybdenum sulfide composite materials, can solve the problems that are not conducive to the application of composite materials, complicated operation steps, etc., achieve large specific surface area and simplify preparation Excellent workmanship and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Preparation of graphite phase carbon nitride / molybdenum sulfide composite material

[0027] The specific preparation method is as follows:

[0028] (1) MoS 2 and melamine in a molar ratio of 1:3 (MoS 2 and melamine (0.160g, 0.378g) were mixed evenly, and after adding 2mL of glycerin, they were fully ground for 60min;

[0029] (2) put the mixture in N 2 Under the protection of the atmosphere, the temperature was raised to 550°C at a heating rate of 5°C / min, and calcined for 4 hours to obtain g-C 3 N 4 / MoS 2 composite material.

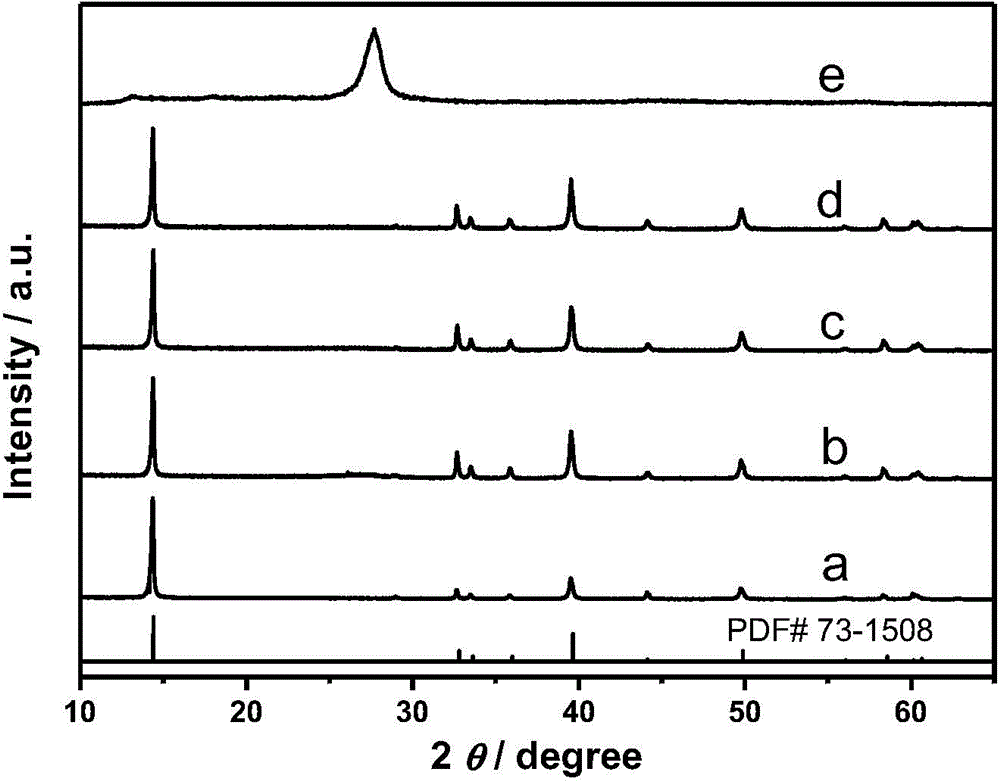

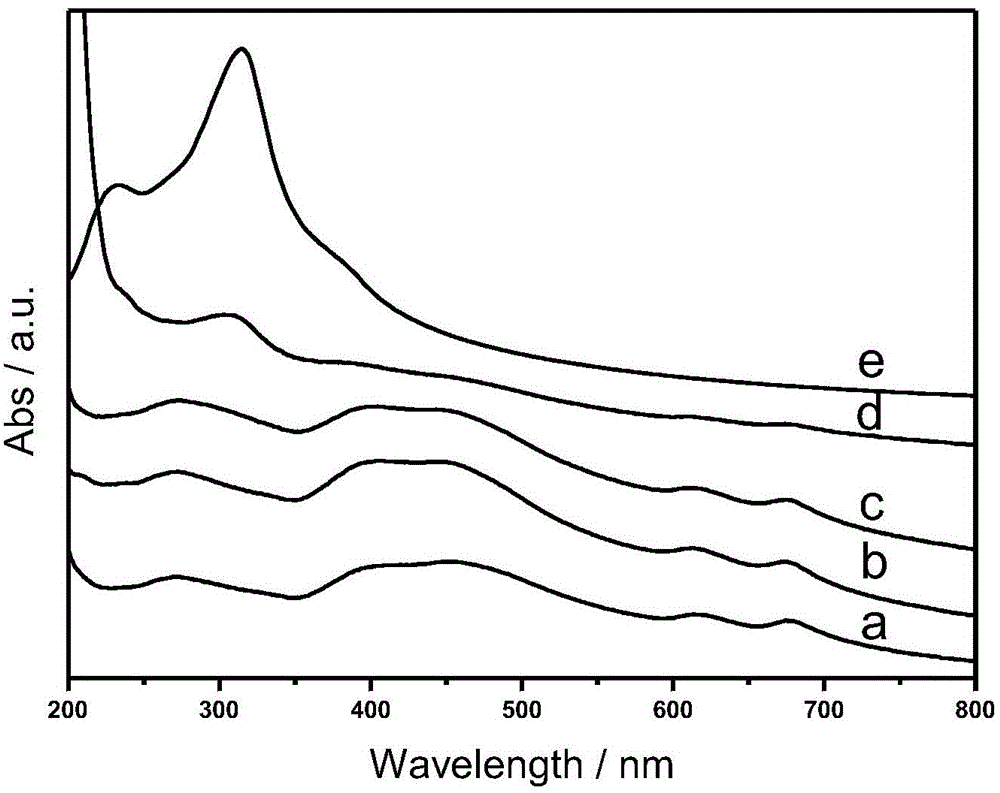

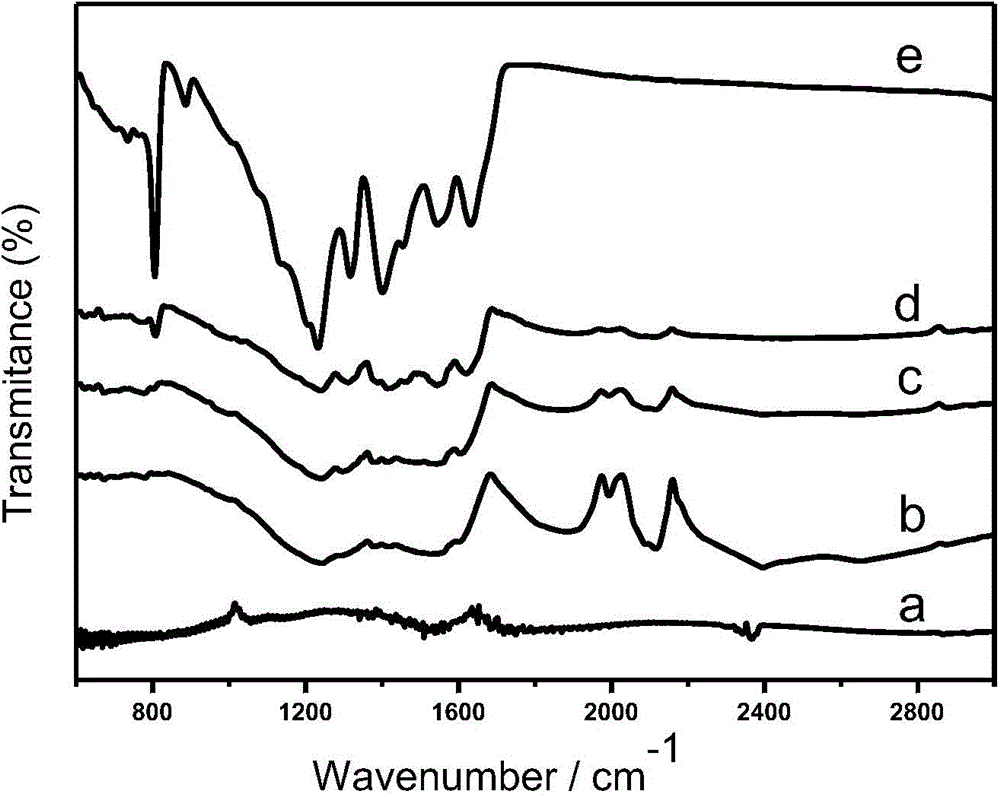

[0030] For the prepared g-C 3 N 4 / MoS 2 The composite materials were analyzed and characterized by XRD, UV-vis and FT-IR respectively. The results are as follows: figure 1 , figure 2 , image 3 shown.

[0031] figure 1 where a is MoS 2 The XRD spectrogram of raw material, b is the g-C that the present embodiment prepares 3 N 4 / MoS 2 XRD spectrum of the composite material, with MoS 2 After comparison with the s...

Embodiment 2

[0034] Embodiment 2: Preparation of graphite phase carbon nitride / molybdenum sulfide composite material

[0035] The specific preparation method is as follows:

[0036] (1) MoS 2 and melamine in a molar ratio of 1:5 (MoS 2 and melamine (0.160g, 0.631g) were mixed evenly, and after adding 2mL of glycerin, they were fully ground for 60min;

[0037] (2) put the mixture in N 2 Under the protection of the atmosphere, the temperature was raised to 550°C at a heating rate of 5°C / min, and calcined for 4 hours to obtain g-C 3 N 4 / MoS 2 composite material.

[0038] For the prepared g-C 3 N 4 / MoS 2 The composite materials were analyzed and characterized by XRD, UV-vis, FT-IR and TEM respectively. The results are as follows: figure 1 , figure 2 , image 3 and Figure 4 shown.

[0039] figure 1 Middle c is the XRD spectrum pattern of the product prepared in this embodiment, and MoS 2 After comparison with the standard card (PDF#73-1508), it is found that it is completely...

Embodiment 3

[0043] Embodiment 3: the preparation of graphite phase carbon nitride / molybdenum sulfide composite material

[0044] The specific preparation method is as follows:

[0045] (1) MoS 2 and melamine in a molar ratio of 1:7 (MoS 2 and melamine (0.160g, 0.883g) were mixed evenly, and after adding 2mL of glycerin, they were fully ground for 60min;

[0046] (2) put the mixture in N 2 Under the protection of the atmosphere, the temperature was raised to 550°C at a heating rate of 5°C / min, and calcined for 4 hours to obtain g-C 3 N 4 / MoS 2 composite material.

[0047] For the prepared g-C 3 N 4 / MoS 2 The composite materials were analyzed and characterized by XRD, UV-vis and FT-IR respectively. The results are as follows: figure 1 , figure 2 and image 3 shown.

[0048] figure 1 Middle d is the XRD figure of the product prepared in this embodiment, and MoS 2 After comparison with the standard card (PDF#73-1508), it is found that it is completely corresponding, indicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com