Method for continuous extraction of corn oil, alcohol soluble protein and yellow pigment from corn gluten meal

The technology of zein and corn yellow powder is applied in the fields of yellow pigment, continuous extraction of corn oil and gliadin, which can solve the problems of no corn yellow powder utilization, waste of resources and the like, achieve easy industrial production, improve economic benefits and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

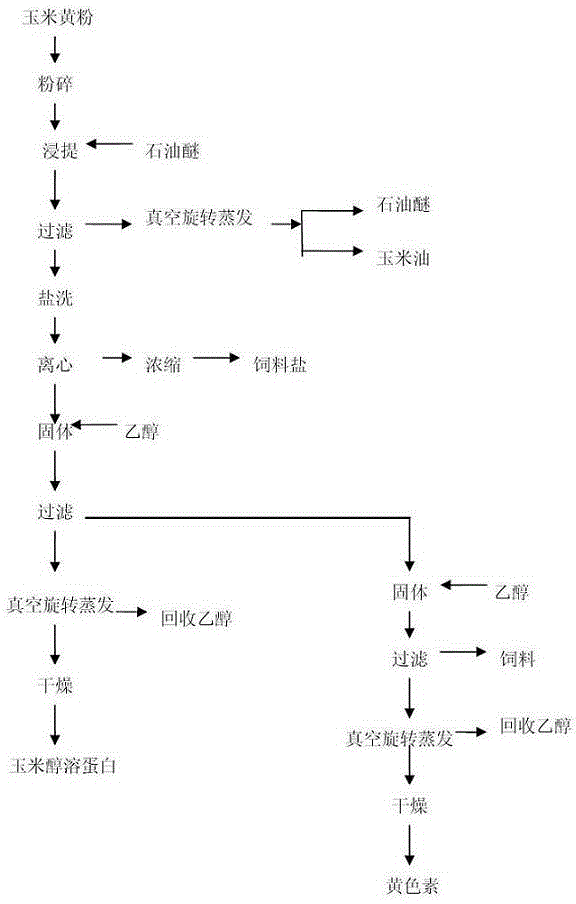

Method used

Image

Examples

Embodiment 1

[0026] 1. Extract corn oil

[0027] Crush 10g corn yellow powder to 120 mesh, soak it in petroleum ether with a material-to-liquid ratio of 1:10 for 8 hours, so that the corn oil is extracted by petroleum ether, filtered, and the corn yellow powder is ready for use. The petroleum ether and corn are evaporated under reduced pressure at 50°C. Oil is separated and petroleum ether is recovered to obtain corn oil with a yield of 11.32%.

[0028] 2. Extract zein

[0029] The corn yellow powder after oil extraction is added to 4% sodium chloride liquid for salt washing, the ratio of material to liquid is 1:8, stirring for 15 minutes, centrifugation, the salt washing liquid is recovered, concentrated, and dried at 50°C to obtain feed salt. 70% ethanol solution was added to the solid obtained after centrifugation, with a material-to-liquid ratio of 1:12, heated in a water bath at 40°C, stirred for 20min, filtered, and the obtained solid was ready for use. The supernatant was concentrated und...

Embodiment 2

[0033] 1. Extract corn oil

[0034] Crush 10g corn yellow powder to 150 mesh, soak it in petroleum ether with a material-to-liquid ratio of 1:12 for 6 hours, so that the corn oil is extracted by petroleum ether, filtered, and the corn yellow powder is ready for use. The petroleum ether and corn are evaporated under reduced pressure at 50°C. Oil is separated and petroleum ether is recovered to obtain corn oil with a yield of 11.97%.

[0035] 2. Extract zein

[0036] The corn yellow powder after oil extraction is added to 4% sodium chloride liquid for salt washing, the material-to-liquid ratio is 1:10, stirring for 20 minutes, centrifugation, the salt washing liquid is recovered, concentrated, and dried at 60°C to obtain feed salt. Add 80% ethanol solution to the solid obtained after centrifugation, with a material-to-liquid ratio of 1:10, heat in a water bath at 35°C, stir for 30min, and filter. The obtained solid is ready for use. The supernatant is concentrated under reduced pressu...

Embodiment 3

[0040] 1. Extract corn oil

[0041] Crush 10g of corn yellow powder to 100 mesh, soak it in petroleum ether with a material-to-liquid ratio of 1:8, extract the corn oil by petroleum ether for 9 hours, filter, and evaporate the corn yellow powder for use at 50°C under reduced pressure. Separate from corn oil and recover petroleum ether to obtain corn oil with a yield of 10.65%.

[0042] 2. Extract zein

[0043] The corn yellow powder after oil extraction is added to 4% sodium chloride liquid for salt washing, the material-to-liquid ratio is 1:12, stirring for 25 minutes, centrifugation, the salt washing liquid is recovered, concentrated, and dried at 70°C to obtain feed salt. Add 60% ethanol solution to the solid obtained after centrifugation with a material-to-liquid ratio of 1:9. Heat in a water bath at 30°C, stir for 40min, and filter. The obtained solid is ready for use. The supernatant is concentrated under reduced pressure at 50°C to recover ethanol. The solids evaporated unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com