Starch based thermoplastic material and preparation method thereof

A thermoplastic material and starch technology, applied in the field of thermoplastic materials, can solve the problems of unsolvable materials and the difficulty of large-scale application of thermoplastic starch-based materials, and achieve the effects of high biomass content, low cost and excellent thermoplastic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

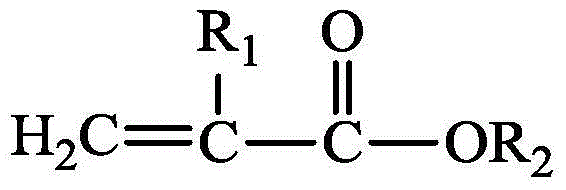

Method used

Image

Examples

Embodiment 1

[0051] 100 parts of modified starch 1 and 0.5 part of potassium persulfate (produced by Sinopharm Group Chemical Reagent Co., Ltd.) were dispersed in 200 parts of water, ultrasonically dispersed to obtain an emulsion, and 100 parts of methyl acrylate (Sinopharm Group Chemical Reagent Co., Ltd.) were added. Production), stirred and reacted in a water bath at 70°C for 12 hours, added a small amount of ethanol to break the emulsion, and dried by suction filtration.

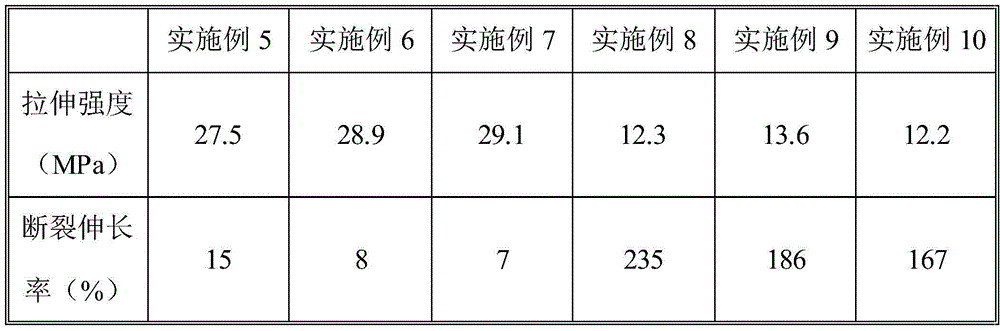

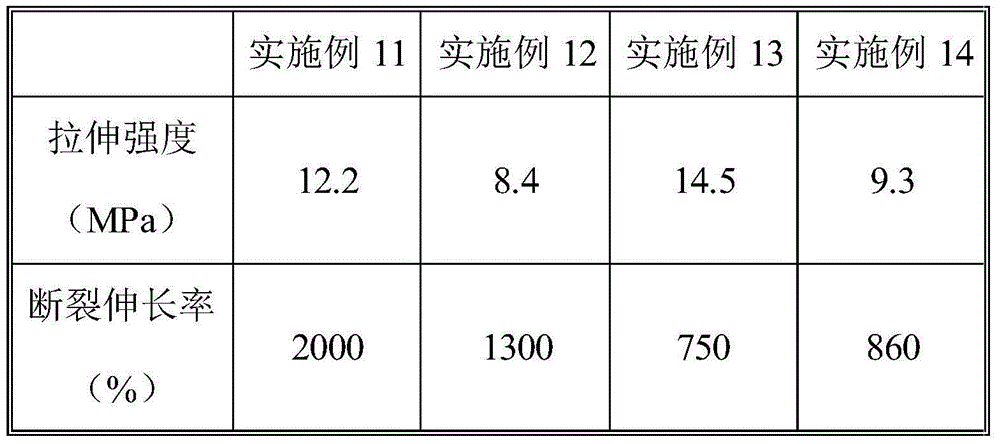

[0052] The starch-based thermoplastic material was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, and was cut into a standard sample according to relevant standards for mechanical property testing. The test results are listed in Table 1.

Embodiment 2

[0054] Except that the modified starch 1 was changed to modified starch 2, and 0.5 parts of potassium persulfate (produced by Sinopharm Chemical Reagent Co., Ltd.) was changed to 5 parts of ammonium persulfate (produced by Sinopharm Chemical Reagent Co., Ltd.), all the other conditions were the same Example 1.

[0055] The starch-based thermoplastic material was hot-pressed by a flat vulcanizer to obtain a 1mm-thick sheet, which was cut into standard specimens for mechanical performance testing according to relevant standards. The test results are listed in Table 1.

Embodiment 3

[0057] Disperse 100 parts of modified starch 3 and 1 part of sodium persulfate (produced by Sinopharm Chemical Reagent Co., Ltd.) in 1000 parts of water, ultrasonically disperse to obtain an emulsion, add 300 parts of ethyl acrylate (produced by Sinopharm Chemical Reagent Co., Ltd. Production), stirred and reacted in a water bath at 70°C for 12 hours, added a small amount of ethanol to break the emulsion, and dried by suction filtration.

[0058] The starch-based thermoplastic material was hot-pressed by a flat vulcanizer to obtain a sheet with a thickness of 1 mm, and was cut into a standard sample according to relevant standards for mechanical property testing. The test results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com