Polysiloxane modified polyamide-amine as well as preparation method and application thereof

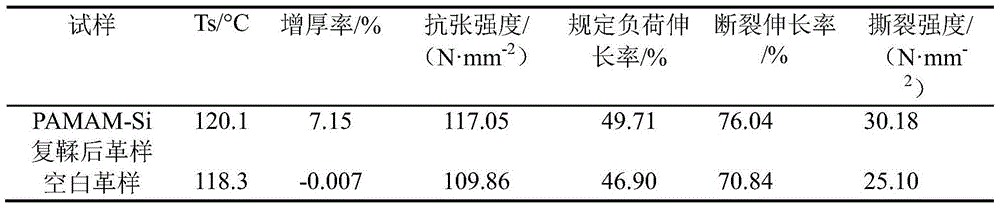

A polysiloxane and polyamide technology, which is applied in the field of polysiloxane-modified polyamide-amine and its preparation, can solve the problems of rare retanning agents, and achieve enhanced physical and mechanical properties and target product yield. High yield, dye uptake and improved dry and wet rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

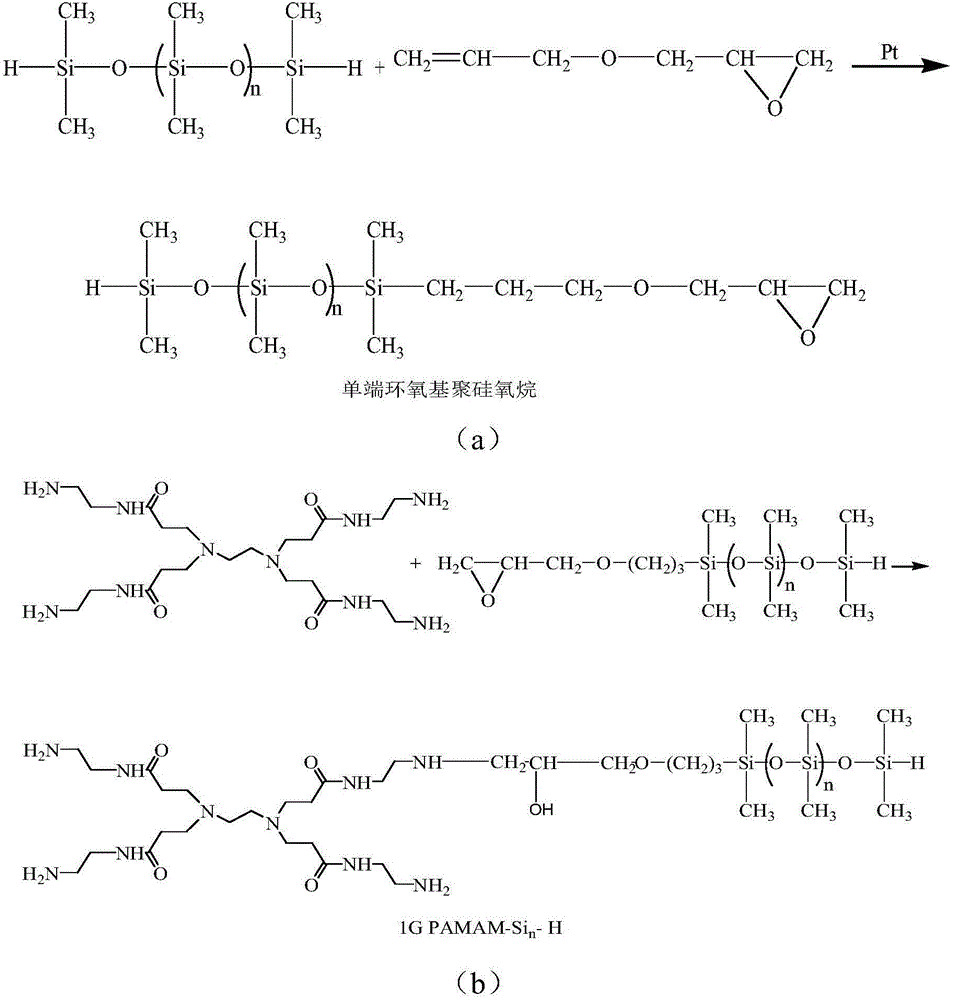

[0024] A kind of preparation method of polyamide-amine modified by polysiloxane of the present invention, comprises the following steps:

[0025] Step 1: Add terminal hydrogen-containing polysiloxane and allyl glycidyl ether with a molar ratio of 1: (0.8 to 1.0) into the reaction vessel, and add catalyst chloroplatinic acid and solvent, mix evenly, heat up and reflux, remove Reaction solvent, after the reaction, remove the solvent toluene at 70-90°C, then dissolve the solution in methanol, let it stand for stratification, take the supernatant, pour out the lower layer of oily liquid, and then distill out the methanol under reduced pressure at 40-60°C , to obtain a crude extract, and then repeat the above purification operation 2 to 3 times to obtain a white transparent oily liquid, that is, a single-end epoxy polysiloxane. The mass of chloroplatinic acid added is 0.15-0.35% of the total mass of reactants, the reaction temperature is 90-110°C, and the reaction time is 4-6h.

...

Embodiment 1

[0029] A preparation method of polyamide-amine modified by polysiloxane, comprising the following steps:

[0030] Step 1: Add terminal hydrogen-containing polysiloxane and allyl glycidyl ether with a molar ratio of 1:0.8, solvent toluene, and catalyst chloroplatinic acid with a total mass of reactants of 0.15% to the reaction vessel, and mix well Raise the temperature to reflux, reflux at 90°C for 4 hours, remove the reaction solvent toluene at 70-90°C after the reaction is completed, then dissolve the solution in methanol, let stand to separate layers, take the supernatant, pour out the lower oily liquid, and then 40 The methanol was distilled off under reduced pressure at ~60°C to obtain a crude extract, and the above purification operation was repeated 2 to 3 times to obtain a white transparent oily liquid, that is, a single-end epoxy polysiloxane.

[0031] Step 2: Add the first-generation polyamidoamine and single-ended epoxy polysiloxane into the reactor at a molar ratio ...

Embodiment 2

[0034] A preparation method of polyamide-amine modified by polysiloxane, comprising the following steps:

[0035] Step 1: Add terminal hydrogen-containing polysiloxane and allyl glycidyl ether with a molar ratio of 1:0.9, solvent toluene, and catalyst chloroplatinic acid with a total mass of reactants of 0.15% to the reaction vessel, and mix well Raise the temperature to reflux, reflux at 90°C for 5 hours, remove the reaction solvent toluene at 70-90°C after the reaction is completed, then dissolve the solution in methanol, stand to separate layers, take the supernatant, pour out the lower oily liquid, and then 40 The methanol was distilled off under reduced pressure at ~60°C to obtain a crude extract, and the above purification operation was repeated 2 to 3 times to obtain a white transparent oily liquid, that is, a single-end epoxy polysiloxane.

[0036] Step 2: Add the first-generation polyamidoamine and single-ended epoxy polysiloxane into the reactor at a molar ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com