Liquid silkscreen conducting resin and preparation method thereof

A technology of conductive adhesive and liquid silk, which is applied in the field of conductive adhesive, can solve the problems of conductive adhesive or conductive adhesive film, such as conductive performance, poor bonding effect, cumbersome use process, and low lamination pass rate, so as to achieve strong production practicability , low production cost, enhanced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Correspondingly, the embodiment of the present invention also provides a preparation method of liquid screen printing conductive adhesive, comprising the following steps:

[0028] S01. According to the formula of the above-mentioned liquid screen printing conductive adhesive, weigh each component;

[0029] S02. adding the conductive silver particles to the epoxy-modified acrylic resin, and dispersing them in the reactor to obtain the first dispersion;

[0030] S03. Add the conductive crystal transistor and the conductive fiber to the above-mentioned first dispersion for dispersion treatment to obtain the second dispersion;

[0031] S04. Add the defoamer and the leveling agent to the above second dispersion for dispersion treatment to obtain a liquid conductive adhesive for screen printing.

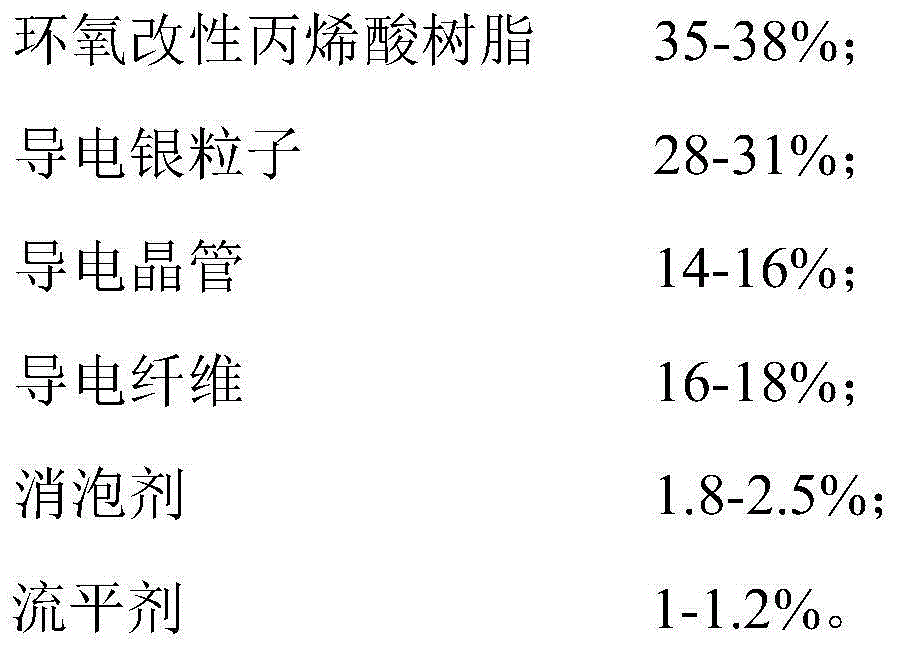

[0032] Specifically, in the above-mentioned step S01 of the embodiment of the present invention, the formula and preferred components of the liquid screen printing conductive adhes...

Embodiment 1

[0040] A liquid screen printing conductive adhesive, based on the total weight of the liquid screen printing conductive adhesive as 100%, including the following components in the following weight percentages:

[0041]

[0042] The preparation method of described liquid screen printing conductive glue, comprises the following steps:

[0043] S11. According to the formula of the above-mentioned liquid screen printing conductive adhesive, weigh each component;

[0044] S12. Add the conductive silver particles to the epoxy-modified acrylic resin, and carry out dispersion treatment in the reactor to obtain the first dispersion. Disperse the damaged grinding disc for 90 minutes;

[0045] S13. Add the conductive crystal transistor and the conductive fiber to the above-mentioned first dispersion for dispersion treatment to obtain the second dispersion. The method of the dispersion treatment is to disperse for 60 minutes under the condition that the rotation speed is 500 rpm;

[...

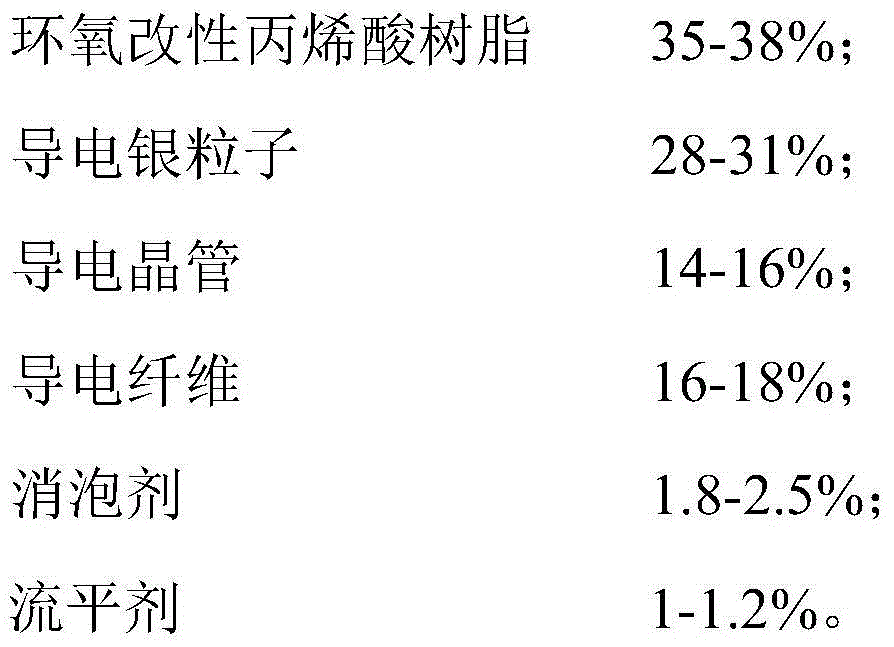

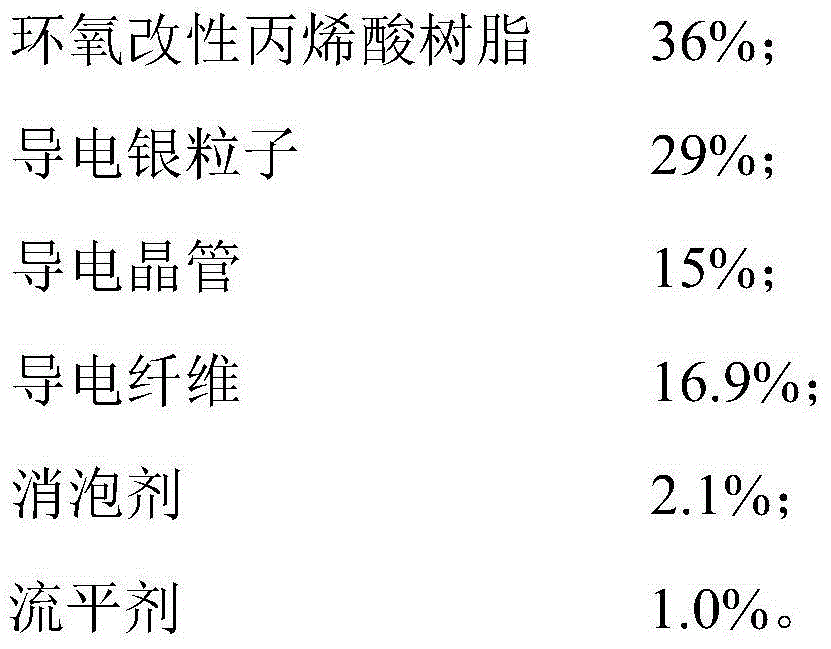

Embodiment 2

[0048] A liquid screen printing conductive adhesive, based on the total weight of the liquid screen printing conductive adhesive as 100%, including the following components in the following weight percentages:

[0049]

[0050] The preparation method of described liquid screen printing conductive glue, comprises the following steps:

[0051] S21. According to the formula of the above-mentioned liquid screen printing conductive adhesive, weigh each component;

[0052] S22. Add the conductive silver particles to the epoxy-modified acrylic resin, and carry out dispersion treatment in the reactor to obtain the first dispersion. Disperse the damaged grinding disc for 85 minutes;

[0053] S23. Add the conductive crystal transistor and the conductive fiber to the above-mentioned first dispersion for dispersion treatment to obtain the second dispersion. The dispersion treatment method is to disperse for 65 minutes under the condition that the rotation speed is 450 rpm;

[0054] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com