A pipeline emergency plugging material

A plugging material and pipeline technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesives, etc., can solve the problems of insufficient mechanical properties of plugging materials, and achieve good water resistance, strong bonding ability, The effect of a wide range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

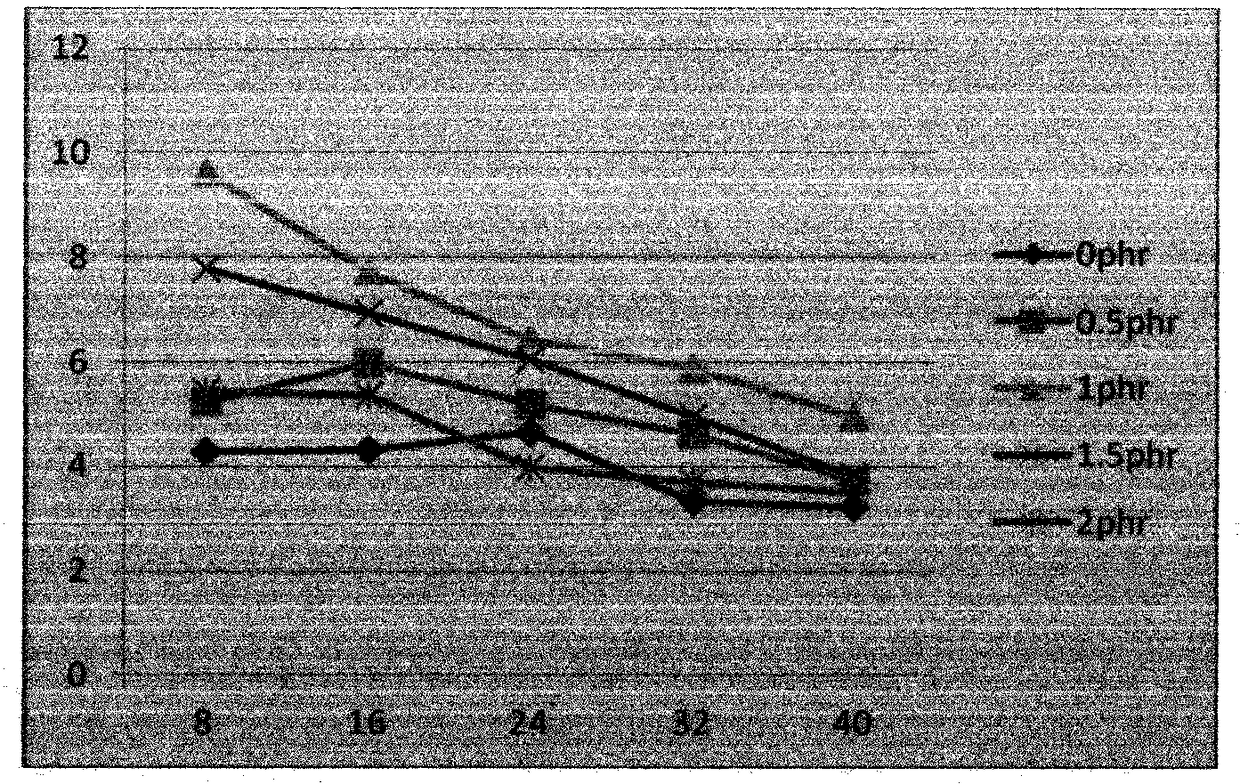

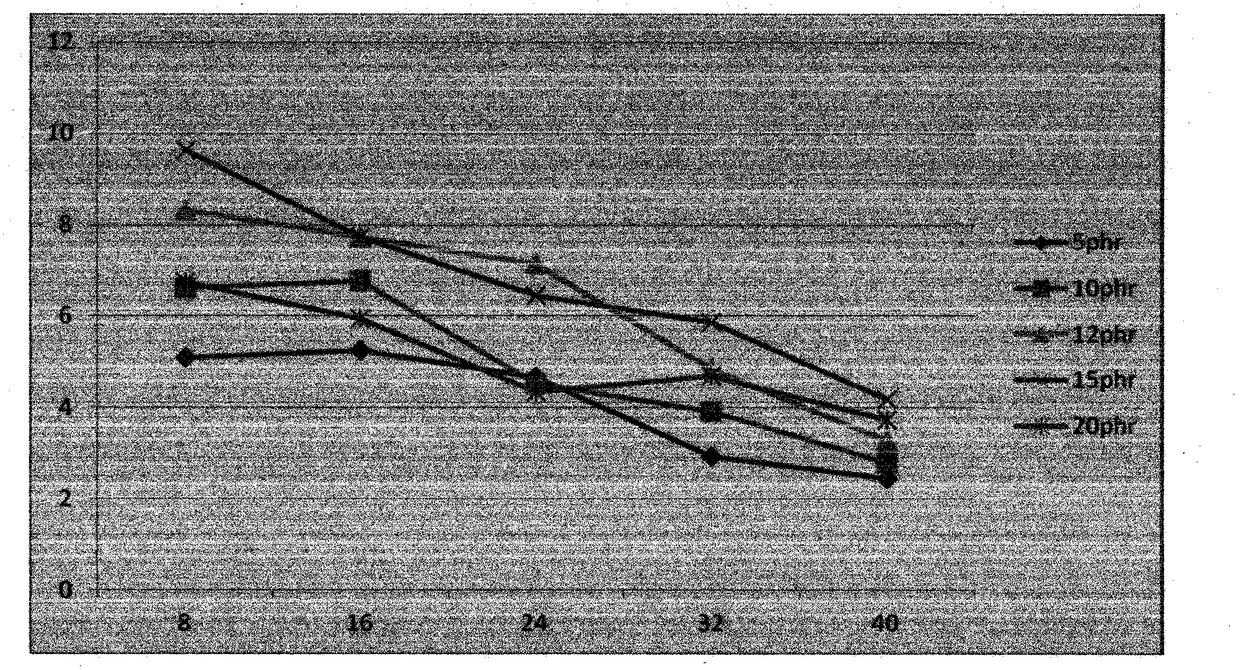

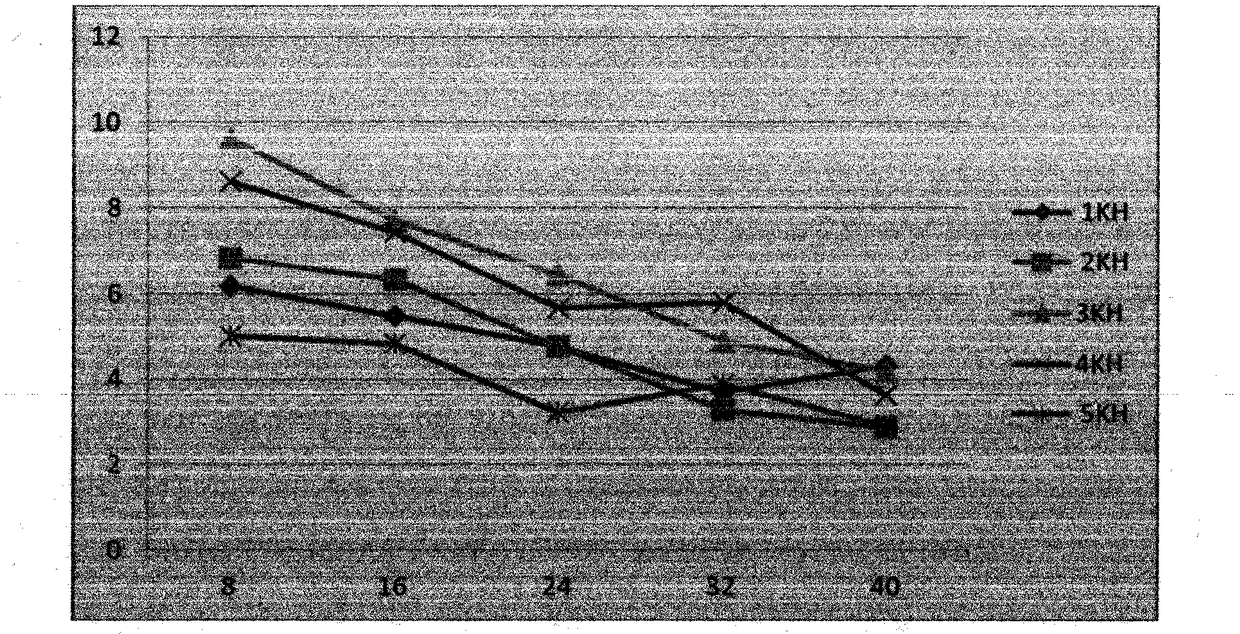

Image

Examples

Embodiment 1

[0048] Embodiment 1 part is filler screening:

Embodiment 1-1

[0050] Components and ratios are: epoxy resin E-44 50%; polyurethane: 2.5%; meteorological silica 0.1%; reactive single epoxy diluent 5%; silane coupling agent KH560 1.5%; talcum powder 25% ; Modified phenalkamine curing agent 15%; DMP-301%.

Embodiment 1-2

[0052] Components and proportions are: epoxy resin E-44 50%; polyurethane: 2.5%; meteorological silica 0.1%; active single epoxy diluent 5%; silane coupling agent KH560 1.5%; diatomaceous earth 25% %; modified phenalkamine curing agent 15%; DMP-301%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com