High-count and high-density downproof fabric and processing method thereof

A high-count, high-density, processing method technology, applied in the direction of textile, biochemical fiber treatment, fabrics, etc., can solve the problems of affecting the thermal comfort of fabrics, not soft enough to feel, and low moisture regain of polyester, so as to reduce the anti-feather performance and organizational structure. Strong, soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

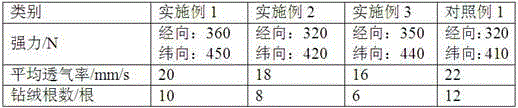

Embodiment 1

[0031] Yarn: The feather-proof fabric is made of 100% long-staple cotton fiber 80S. The long-staple cotton fiber has soft handle, soft and bright luster, good yarn strength, evenness and less hairiness. The weaving specification is 80S*80S / 173*156.

[0032] Weaving process: warping → sizing → threading → reeding → weaving. The fabric sizing process is that the average single yarn strength of the yarn is 170N, and the Uster evenness coefficient of variation is 12%. Air-jet loom is used for weaving, wherein the weaving yarn tension is 450kg, the vehicle speed is 450m / min, the opening time is 250°, the air pressure of the main nozzle is 0.20Mpa, and the air pressure of the auxiliary nozzle is 0.25Mpa.

[0033] Fabric structure: The structure of the fabric structure adopts the plain weave interweaving method with stable structure, and the warp and weft yarns are woven on the air-jet loom according to the interweaving rule of one up and one down.

Embodiment 2

[0044] Yarn: The feather-proof fabric is made of 100% long-staple cotton fiber 100S. The long-staple cotton fiber has soft handle, soft and bright luster, good yarn strength, evenness and less hairiness. The weaving specification is 100S*100S / 200*170.

[0045] Weaving process: warping → sizing → threading → reeding → weaving. The average single yarn strength of the yarn is 150N, and the Uster evenness coefficient of variation is 14%. Air-jet loom is used for weaving, wherein the weaving yarn tension is 350kg, the vehicle speed is 500m / min, the opening time is 280°, the air pressure of the main nozzle is 0.15Mpa, and the air pressure of the auxiliary nozzle is 0.20Mpa.

[0046] Fabric structure: The structure of the fabric structure adopts the plain weave interweaving method with stable structure, and the warp and weft yarns are woven on the air-jet loom according to the interweaving rule of one up and one down.

[0047] Sizing: Starch sizing is used for sizing, which is easy...

Embodiment 3

[0056] Yarn: The feather-proof fabric is made of 100% long-staple cotton fiber 100S. The long-staple cotton fiber has soft handle, soft and bright luster, good yarn strength, evenness and less hairiness. The weaving specification is 100S*100S / 200*170.

[0057] Weaving process: warping → sizing → threading → reeding → weaving. The average single yarn strength of the yarn is 150N, and the Uster evenness coefficient of variation is 14%. Air-jet loom is used for weaving, wherein the weaving yarn tension is 350kg, the vehicle speed is 500m / min, the opening time is 280°, the air pressure of the main nozzle is 0.15Mpa, and the air pressure of the auxiliary nozzle is 0.20Mpa.

[0058] Fabric structure: The structure of the fabric structure adopts the plain weave interweaving method with stable structure, and the warp and weft yarns are woven on the air-jet loom according to the interweaving rule of one up and one down.

[0059] Sizing: Starch sizing is used for sizing, which is easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com