Self-supporting method for surrounding rock of soft rock roadway and stirring injection drilling rig for support

A soft rock and roadway technology, applied in the field of stirred injection drilling rigs, can solve problems such as early release of masonry support body stress, anchor-spray support, unsatisfactory effect of anchor-spray combined with anchor cable support, and large roadway deformation. Achieve the effect of improving construction safety and using mechanization level, good self-supporting effect and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Description of the supporting method

[0039] A self-supporting method for the surrounding rock of a soft rock roadway, the steps are: crushing the soft rock of the soft rock surrounding rock of the roadway, stirring and mixing the curing agent, and compacting it at the rear, mixing the curing agent and the chopped soft rock The rock is fully mixed, so that the surrounding rock of the roadway fully mixed with the curing agent is basically solidified in situ to form a supporting rock mass with supporting capacity, and the surrounding rock of the roadway itself is consolidated as aggregate to harden and become complete.

[0040] The present invention takes 1200mm as an example to further illustrate: after part of the soft rock surrounding rock reaches a certain hardness, the thicker the hardened soft rock, the higher the supporting strength. It is to use physical and chemical methods to add a curing agent that can harden the soft rock; the surrounding rock of th...

Embodiment 2

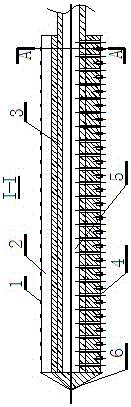

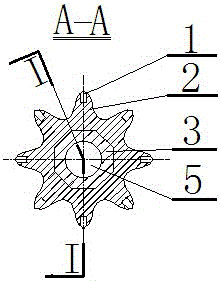

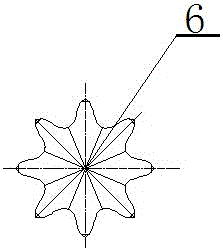

[0044] Example 2 Explanation of the Stirring Drilling Rig

[0045] A stirring injection drilling rig for soft rock roadway support, comprising a drill bit power box 10, a lifting rocker arm 11, a hydraulic jack 12, a left and right turntable 14, a grouting mixing mechanism 15, a machine body 16, and a walking crawler belt 17, and a pair of A gear-type meshing drill bit 8, the drill bit is sleeved on one end of the octagonal drill rod 3, and the other end of the octagonal drill rod 3 passes through the octagonal holes at the center of the two power output gear shafts of the drill power box 10; The top of the teeth of the drill bit is provided with small serrations 1, and each tooth is equidistantly equipped with small serrations 1, and the small serrations are arranged radially and spirally on the teeth 2, and the spiral directions of the two drill bits are opposite; A small pulp hole 4, the small pulp hole 4 on the gear teeth is arranged in the middle between the two small ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com