A method for measuring the three-dimensional microscopic topography of ultra-precision turning surfaces based on the characteristics of visible light reflection spectrum

A technology of reflection spectrum and measurement method, which is applied in the field of surface microscopic topography measurement, can solve the problems of slow measurement speed, unreliability of the surface to be measured, and limitation of measurement area, and achieve small impact on measurement accuracy, non-destructive quantitative measurement, and measurement high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

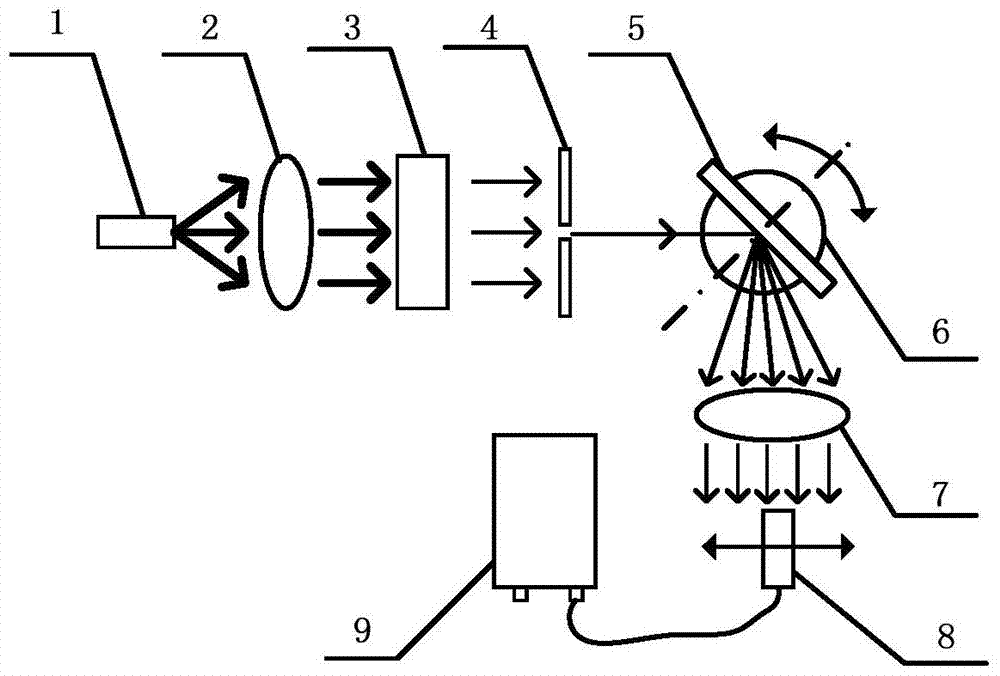

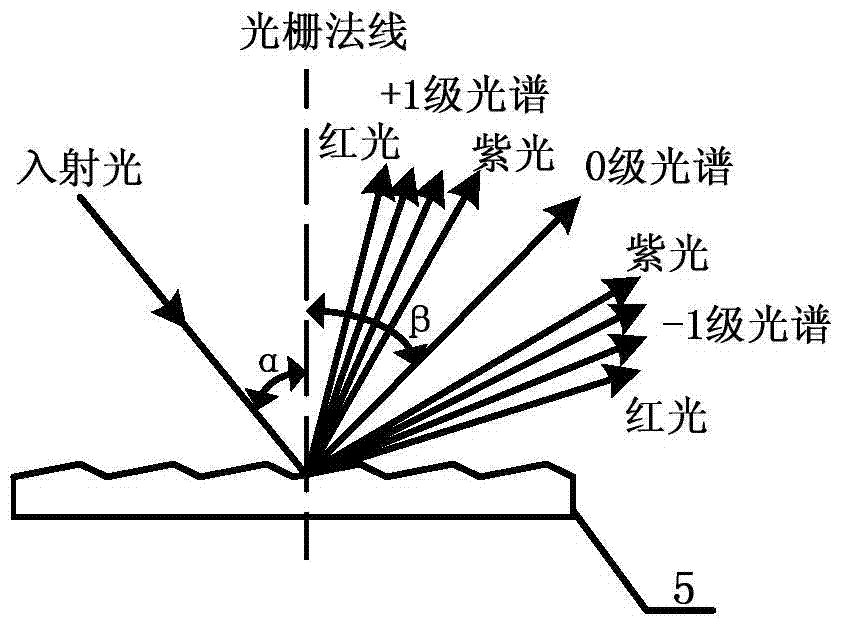

[0034] Such as figure 1 As shown, a measuring device for three-dimensional microscopic topography of an ultra-precision turning surface based on the reflectance spectrum characteristics of visible light is composed of a visible light source 1, a collimating lens 2, a linear attenuation film 3, a small hole diaphragm 4, a workpiece to be measured 5, The rotary table 6, the lens 7, the optical fiber measuring head 8 and the spectrometer 9 are composed. The incident light output by the visible light source 1 is modulated by the collimating lens 2 and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com