Method for evaluating corrosivity index of transformer station soil to copper grounding grid

A copper grounding grid and index evaluation technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of not considering the annual average ambient temperature and soil air capacity of substations, and inaccurate evaluation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

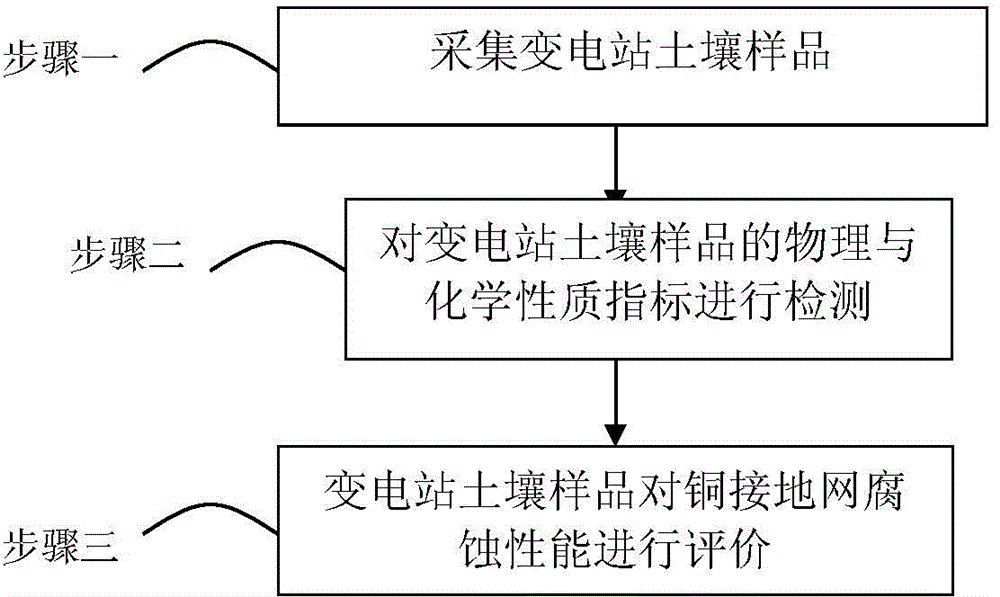

[0016] Specific embodiment one: the substation soil of the present embodiment is characterized in that it realizes according to the following steps to the index evaluation method of copper ground grid corrosion:

[0017] 1. Collect substation soil samples;

[0018] 2. Detect the physical and chemical properties of substation soil samples;

[0019] 3. Evaluation of the corrosion performance of copper grounding grid by soil samples in substations:

[0020] According to soil type, soil resistivity, pH value, water content, soluble Cl - amount, soluble SO 4 2- According to the test results of the nine indicators of copper content, air capacity, oxidation-reduction potential and regional annual average temperature, the copper evaluation index Z i , and calculate the total evaluation index B E , the corrosion performance of soil to galvanized steel grounding grid was evaluated by soil corrosion evaluation grade.

specific Embodiment approach 2

[0021] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is that step one is specifically:

[0022] Select a certain diagonal line of the substation site, and dig four test pits with a diameter of 0.8-1.0m along the diagonal direction; among them, the distance between each test pit is 10m-11m. The depth is the same; about 2kg to 2.5kg of soil samples are taken in each test pit.

[0023] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Specific implementation mode three: the difference between this implementation mode and specific implementation mode one or two is that step two is specifically:

[0025] According to the "Material Soil Corrosion Test Method" compiled by the National Soil Corrosion Test Website, and according to the correlation between the corrosion degree of galvanized steel grounding grid and the physical and chemical properties of the soil, the soil samples of the substation were collected, and the soil type, soil resistivity, pH value, water content, soluble Cl - content, soluble SO 4 2- Content, air capacity and oxidation-reduction potential are detected, and the monitoring data of the regional average annual temperature are obtained from the Meteorological Bureau in the area where the substation is located.

[0026] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Uniform corrosion rate | aaaaa | aaaaa |

| Uniform corrosion rate | aaaaa | aaaaa |

| Uniform corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com