Deep trench isolated anti-crosstalk photoelectric detector and manufacturing method thereof

A photodetector, anti-crosstalk technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of poor resistance-capacitance characteristics, loss of light energy, reduced photodetector responsivity, etc., to reduce the capacitance area. Small, improve the response speed, reduce the effect of intrinsic dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

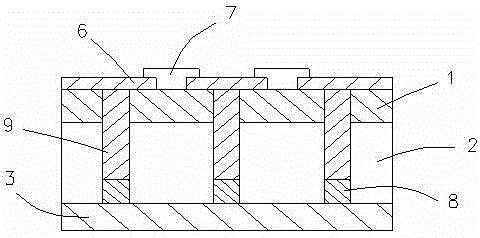

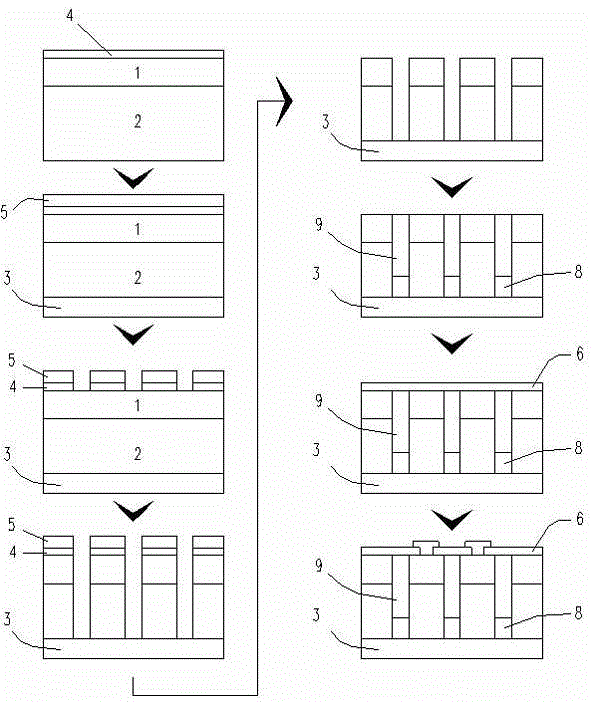

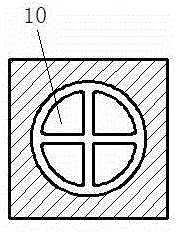

[0023] A deep groove isolation anti-crosstalk photodetector, comprising a P-i-N layered structure sequentially stacked by a P-type diffusion layer 1, a substrate layer 2 and an N-type diffusion layer 3, and an isolation region is arranged on the P-i-N layered structure , the isolation region divides the photosensitive surface of the P-i-N layered structure into multiple quadrants, and its innovation is that the isolation region is realized by the following structure: a deep groove is made on the photosensitive surface of the P-i-N layered structure, and the cross-section of the deep groove The contour matches the outer contours of multiple quadrants, the axial direction of the deep groove is the same as the stacking direction of the P-i-N layered structure, the depth of the deep groove reaches the upper end surface of the N-type diffusion layer 3, and the deep groove is filled with an insulating substance.

[0024] Further, the insulating material adopts spin-on glass and polyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com