Traditional Chinese medicine combination for migraine treatment and production method thereof

A composition and technology for migraine, applied in the field of traditional Chinese medicine, can solve the problems of large toxic and side effects of western medicine, unsatisfactory treatment effect of traditional Chinese medicine, unsustainable treatment effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

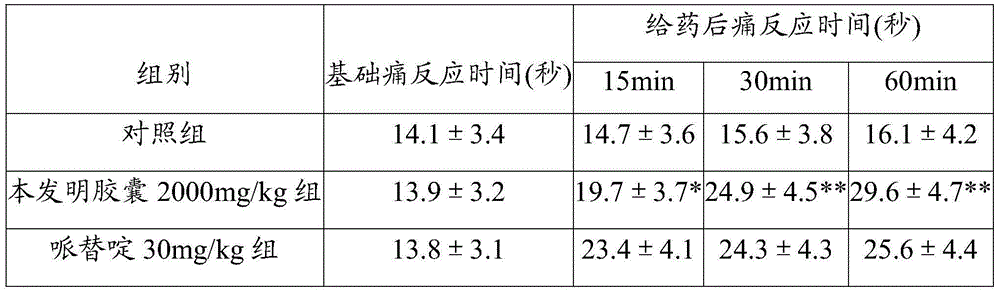

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the above-mentioned traditional Chinese medicine composition, comprising:

[0042] Mix the components in the raw material components in proportion, soak in 5-8 times the amount of water for 12-24 hours, extract the volatile oil with steam distillation, save the distilled medicinal residue and medicinal liquid separately, and recover the medicinal liquid under reduced pressure Concentrate to a relative density of 1.05-1.15 at 70-90°C to obtain A; the above-mentioned volatile oil is dissolved in ethanol at a ratio of 1:1, and the colloid milling method is used, and the ratio of volatile oil to β-cyclodextrin is 1:6-10, β -The ratio of cyclodextrin to water is 1:1-3, adopt appropriate grinding speed to grind for 15-30 minutes for clathrate, obtain paste, dry at 40-60°C, and pulverize to obtain clathrate B; Continue to extract the residue with 60-80% ethanol under reflux for 1-3 times, each time 6-10 times the solv...

Embodiment 1

[0047] Get 8 parts by weight of benzoin, 6 parts by weight of agrimony, 4 parts by weight of nutmeg, 5 parts by weight of Alisma, 4 parts by weight of agarwood, 8 parts by weight of safflower, 8 parts by weight of jujube, 5 parts by weight of Ligustrum lucidum, and Asarum 4 parts by weight, 7 parts by weight of Prunella vulgaris, 10 parts by weight of cassia seed, 8 parts by weight of lovage, 12 parts by weight of Puhuang, 5 parts by weight of Fangfeng, 6 parts by weight of chrysanthemum, mixed in proportion; soaked in 5 times the amount of water for 12 hours, water The steam distillation method extracts the volatile oil, and the distilled medicinal residue and medicinal liquid are stored separately, and the medicinal liquid is recovered under reduced pressure and concentrated to a relative density of 1.05 at 70°C to obtain A; the above-mentioned volatile oil is dissolved by adding ethanol at a ratio of 1:1, and the colloidal milling method is used. The ratio of volatile oil to...

Embodiment 2

[0051] Take 12 parts by weight of benzoin, 10 parts by weight of agrimony, 10 parts by weight of nutmeg, 10 parts by weight of Alisma, 9 parts by weight of agarwood, 16 parts by weight of safflower, 17 parts by weight of jujube, 11 parts by weight of Ligustrum lucidum, and Asarum 10 parts by weight, 14 parts by weight of Prunella vulgaris, 18 parts by weight of Semen Cassiae, 12 parts by weight of lovage, 18 parts by weight of Puhuang, 10 parts by weight of Fangfeng, 12 parts by weight of Chrysanthemum, mixed in proportion; Mix them according to the proportion, soak in 8 times the amount of water for 24 hours, extract the volatile oil by steam distillation, save the distilled medicinal residue and medicinal liquid, recover and concentrate the medicinal liquid under reduced pressure until the relative density is 1.15 at 90°C to obtain A; the above-mentioned volatile oil Add ethanol at a ratio of 1:1 to dissolve, use the colloid milling method, the ratio of volatile oil to β-cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com