Tail gas purification method and device for thermal desorption of organic polluted soil

A tail gas purification device and organic pollution technology, applied in the restoration of polluted soil, chemical instruments and methods, separation methods, etc., can solve the problems of increasing costs and increasing energy consumption, achieving zero emissions and reducing the amount of hazardous waste generated , the effect of reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

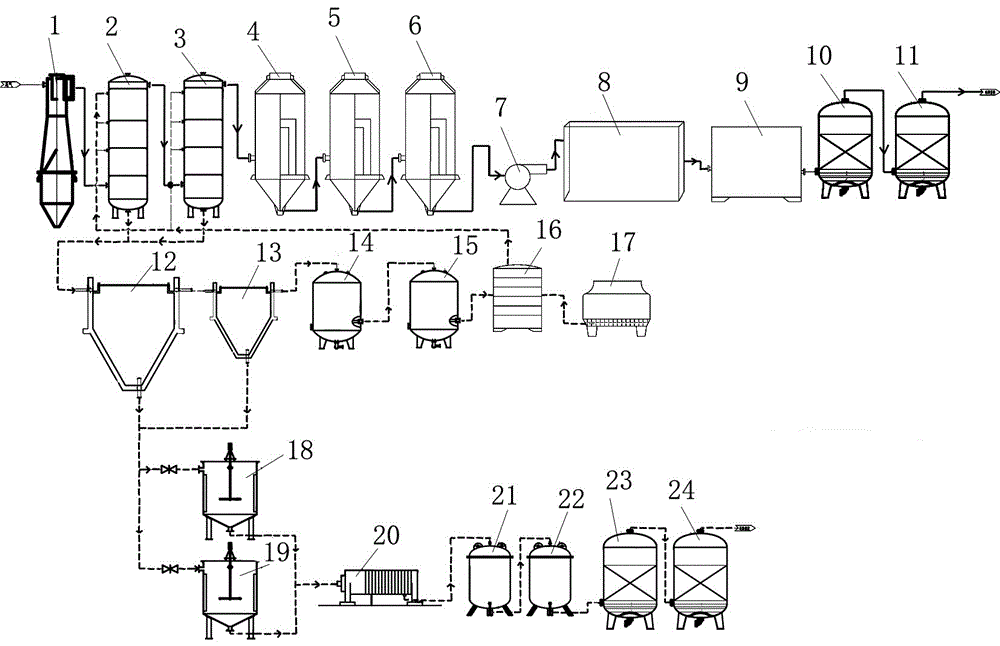

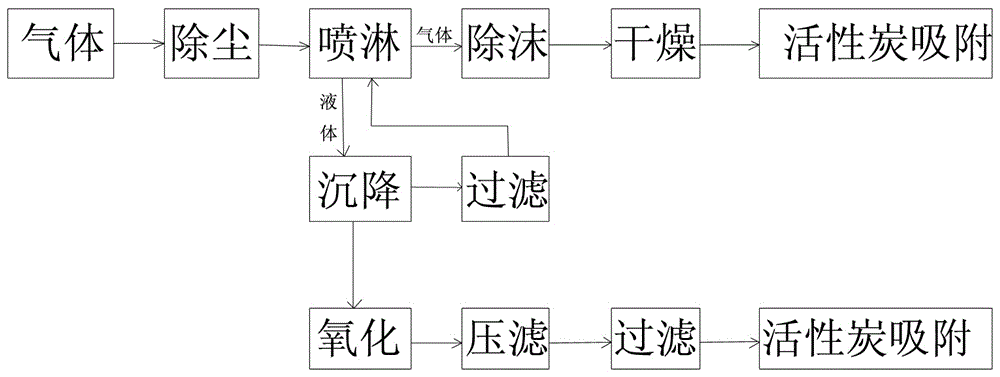

[0018] See attached picture. The tail gas purification device in this embodiment includes a cyclone dust collector 1, one end of the cyclone dust collector 1 is connected to the dusty high-temperature tail gas outlet of the front-end equipment, the other end is connected to the gas inlet at the bottom of the primary spray tower 2, and the top of the primary spray tower 2 The gas outlet is connected to the gas inlet at the bottom of the secondary spray tower 3, and the gas outlet at the top of the secondary spray tower 3 is connected to the primary demister 4; the primary demister 4, the secondary demister 5 and the tertiary demister 6 Connected in series, the three-stage demister 6 is sequentially connected to the induced draft fan 7, the cold dryer 8 and the regenerator 9, and the regenerator 9 is connected to the primary gas activated carbon adsorption tank 10 and the secondary gas activated carbon adsorption tank 11.

[0019] The liquid outlet at the bottom of the primary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com