A welding jig for irregular parts and its welding method

A technology for welding fixtures and parts, applied in vehicle parts, welding equipment, welding equipment, etc., can solve the problems of reduced welding efficiency and safety, poor position accuracy of welding parts, affecting work progress, etc., to save energy consumption, improve Welding efficiency and welding quality, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

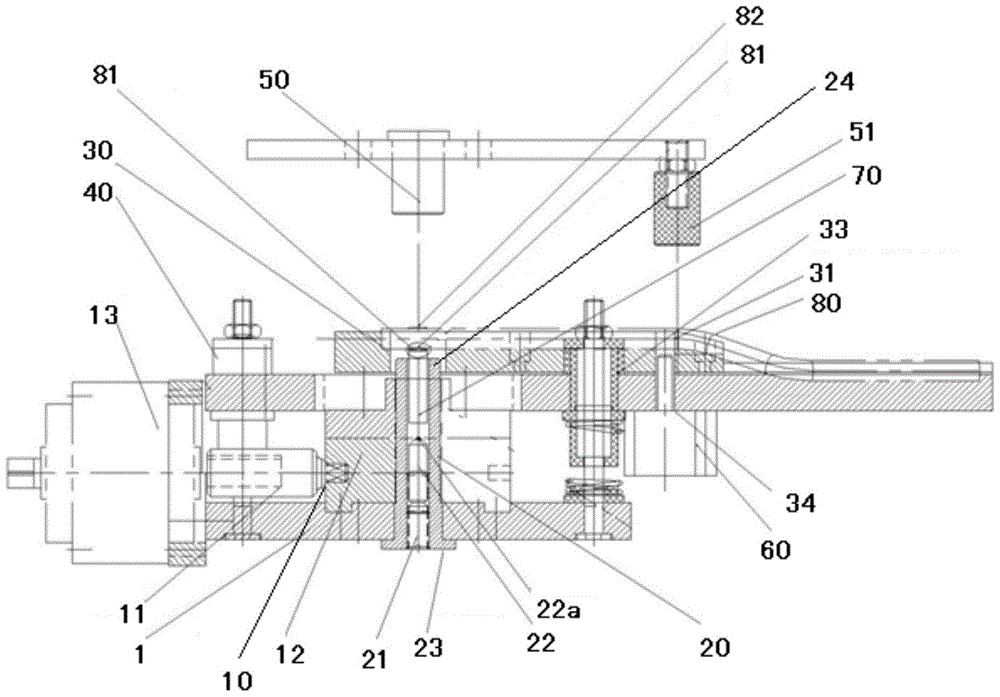

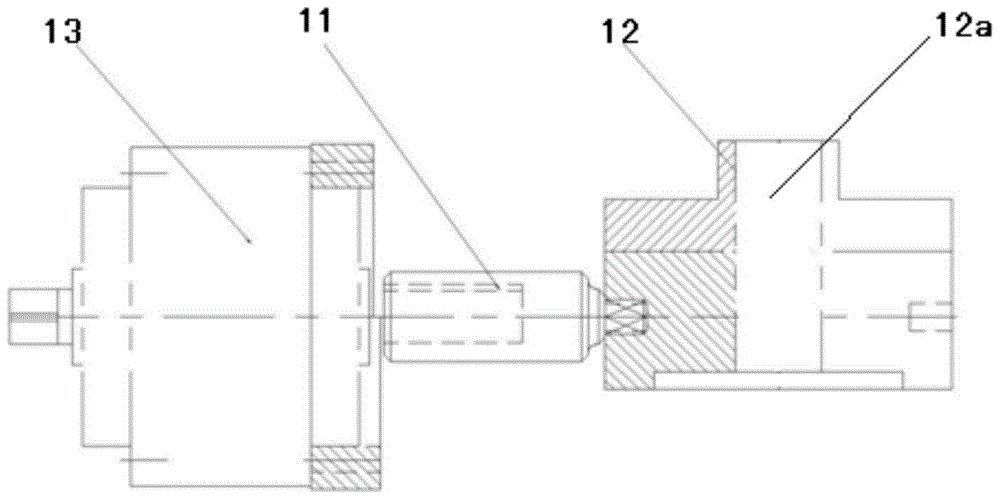

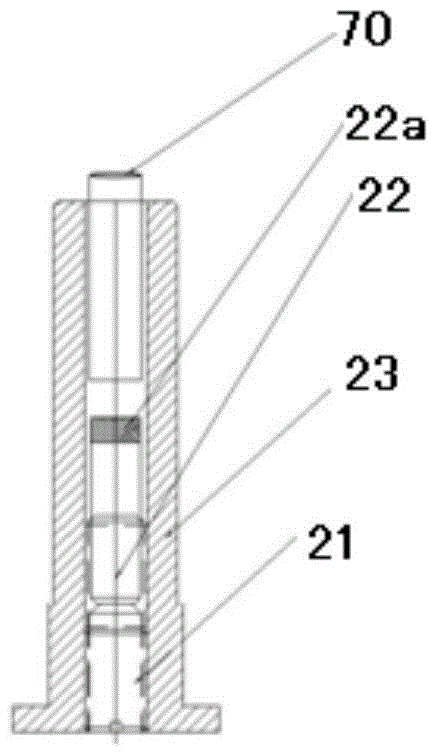

[0044] see Figure 1 to Figure 9As shown, the present invention discloses a welding fixture for irregular parts, including a base 1 and a clamping device 10 installed on the base 1. The clamping device 10 consists of a driving rod 11 and clamps connected to the two ends of the driving rod 11 respectively. Clamping claw cover 12 and driving mechanism 13 are formed, and the middle part of clamping claw cover 12 is provided with the clamping hole 12a that vertically passes through clamping claw cover, and driving mechanism 13 can be driven by air cylinder or oil cylinder or motor drive, and it according to actual situation It needs to be determined; the clamping claw sleeve 12 maintains self-locking to prevent loosening when clamping the three-lobe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com