Preparation method of early-age high-moisture concrete

A concrete and early-age technology, which is applied in the field of preparation of high-moisture-retaining concrete at an early age, can solve the problems of reduced strength, high cost, poor compatibility, etc., and achieves improved frost resistance, less residue, and improved early crack resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

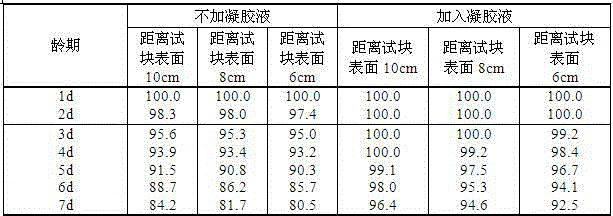

Image

Examples

Embodiment 1

[0028] (1) An early-age high moisture-retaining concrete, its components and dosage per cubic meter of concrete are as follows: 175kg of cement, 40kg of fly ash, 110kg of mineral powder, 848kg of river sand, 1010kg of gravel, 20kg of gel solution, Water agent 4.88kg, expansion agent 28kg, water 152kg.

[0029] (2) Mix the polymer gel and water at a ratio of 1:14, stir with a blade with a shearing device for 5 minutes, and then saturate and absorb water for 48 hours to obtain a gel solution.

[0030] (3) Add gravel and river sand to the mixer according to the raw material ratio in step (1), and dry mix for 15 seconds; then add cement, mineral powder, fly ash, and expansion agent into the mixer, and continue to dry mix for 15 seconds; then add the reduced The water agent, water and the gel solution obtained in step (2) are added to the mixer, and wet mixed for 5 minutes to obtain the mixture; the mixture is poured, vibrated, and cured, and the high-moisture concrete is obtained ...

Embodiment 2

[0042] (1) An early-age high-humidity concrete, its components and dosage per cubic meter of concrete are as follows: 230kg of cement, 60kg of fly ash, 60kg of mineral powder, 785kg of river sand, 1055kg of gravel, gel Liquid 20 kg, water reducer 7.5 kg, expansion agent 30 kg, water 175 kg.

[0043] (2) Mix the polymer gel and water at a ratio of 1:14, stir with a blade with a shearing device for 3 minutes, and then saturate and absorb water for 48 hours to obtain a gel solution.

[0044] (3) Add gravel and river sand to the mixer according to the raw material ratio in step (1), and dry mix for 15 seconds; then add cement, mineral powder, fly ash, and expansion agent into the mixer, and continue to dry mix for 15 seconds; The glue and water are added to the mixer, and wet mixed for 5 minutes to obtain the mixture; the mixture is poured, vibrated, and cured, and the high-moisture concrete can be obtained after 7 days.

[0045] Described cement is P.O42.5 cement.

[0046] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com