Penetration-resistant ultra-high performance concrete

An ultra-high-performance, concrete technology, applied in the field of concrete materials, can solve the problems of high brittleness of ultra-high-strength concrete, inability to meet the requirements of high resistance and high penetration resistance of protective engineering, and weak penetration resistance. Excellent anti-penetration ability, high effect of anti-penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The following embodiments of the present invention adopt the same preparation process.

[0035] First, pour the glue material and fine aggregate into the forced mixer, and stir for 2-3 minutes until uniform;

[0036] Then pour in the coarse aggregate and stir for 1 min;

[0037] Add water reducing agent and water, stir for 3 minutes;

[0038] Slowly pour in steel fibers, stir for 3 minutes until the material is evenly discharged, and the penetration-resistant ultra-high performance concrete of the present invention can be obtained.

[0039] The prepared concrete was placed in the mold, vibrated on a vibrating table for 1min, and after standing for 24h, the mold was removed.

[0040] Finally, place the formed concrete specimen in a standard curing room with a temperature of 20°C ± 2°C and a humidity above 95% for curing for performance testing.

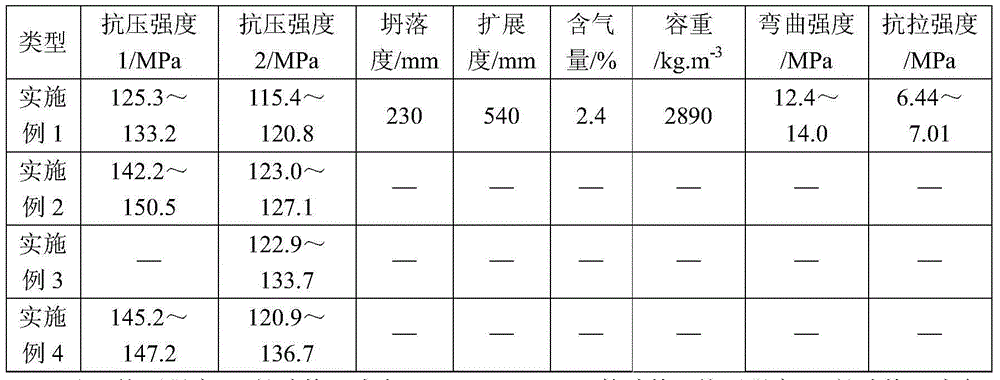

[0041] The performance detection of the embodiment is carried out according to the ordinary concrete test standard GB50081-...

Embodiment 1

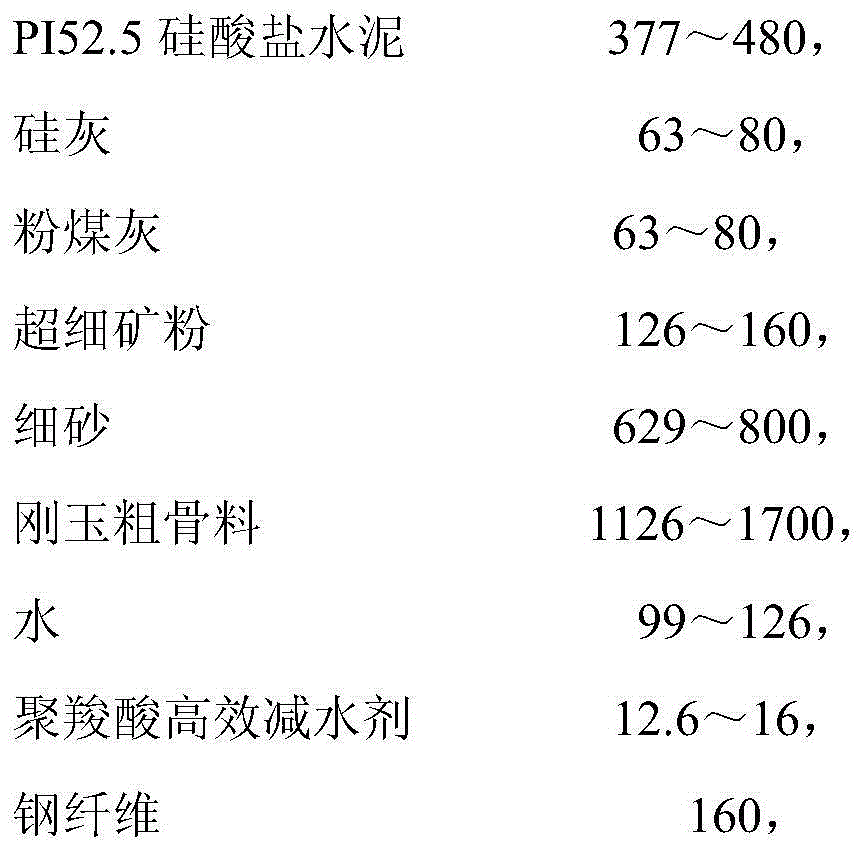

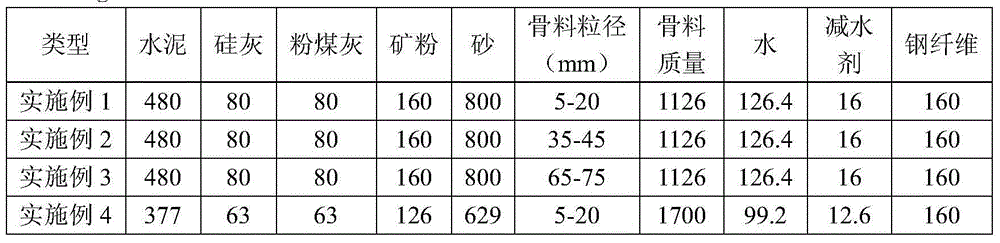

[0050] Ultra-high performance corundum aggregate steel fiber reinforced concrete, including:

[0051] PI52.5 Portland cement 480kg, silica fume 80kg, fly ash 80kg, ultrafine mineral powder 160kg, fine sand with a particle size of 0.25-0.35mm 800kg, corundum gravel with a particle size of 5-20mm 1126kg, polycarboxylic acid Type superplasticizer 16kg, steel fiber 160kg. The diameter of the steel fibers is 0.175 mm and the length is 13 mm.

Embodiment 2

[0053] Ultra-high performance corundum aggregate steel fiber reinforced concrete, including:

[0054] PI52.5 Portland cement 480kg, silica fume 80kg, fly ash 80kg, ultrafine mineral powder 160kg, fine sand with a particle size of 0.25-0.35mm 800kg, corundum gravel with a particle size of 35-45mm 1126kg, polycarboxylic acid Type superplasticizer 16kg, steel fiber 160kg. The diameter of the steel fibers is 0.175 mm and the length is 13 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com