Scraper conveyor re-manufacturing method

A conveyor and scraper type technology, which is applied in the field of scraper conveyor remanufacturing, can solve the problem that the scraper conveyor can not be reused for the remaining life of the groove steel, the middle plate or the bottom plate, and the wear resistance of the fuselage components is inconsistent. , the scrapping of fuselage components, etc., to achieve the effect of high hardness, good wear resistance and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

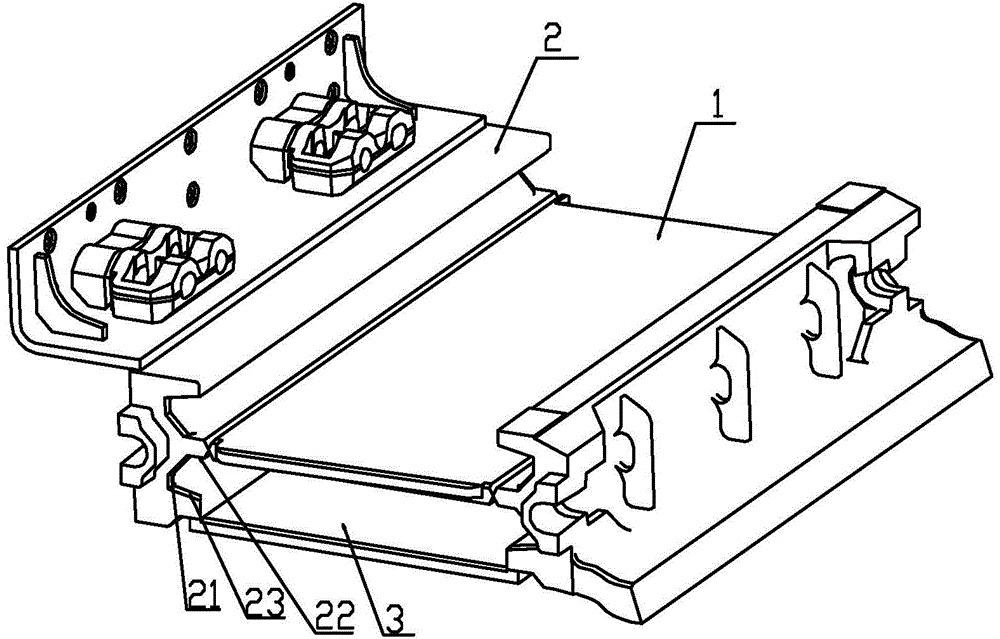

Image

Examples

Embodiment 1

[0050] A method for remanufacturing a scraper conveyor, the remanufacturing method comprising:

[0051](1) Use high-pressure water and shot blasting cleaning technology to carry out non-chemical cleaning methods on the fuselage components of waste scraper conveyors to remove pollutants on the surface of parts and pressure surfaces, and use soft abrasive sandblasting, shot blasting, and high-pressure water Jet cleaning and other technologies remove oxides, carbon deposits, oil stains and other pollutants on the surface of parts, so that the middle plate, bottom plate and channel side steel show metallic luster; after this step, the measurement is more accurate;

[0052] (2) Use a metal thickness gauge to measure the thickness of the head, tail, transition groove, and middle groove of the worn scraper conveyor, and determine the amount of wear failure. The amount of wear failure = thickness of the new product - remaining thickness after wear, chain path Abrasion failure amount i...

Embodiment 2

[0075] The same parts of this embodiment and Embodiment 1 will not be described again. The difference is that, when performing laser cladding in this embodiment, the laser power used is 2.8KW, and the laser scanning speed is 4mm / s.

Embodiment 3

[0077] The same parts of this embodiment and Embodiment 1 will not be described again. The difference is that when performing laser cladding in this embodiment, the laser power used is 3.2KW, and the laser scanning speed is 8mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com