Method for industrial production of polyester filament yarn by using polyester waste yarn

A polyester filament and waste filament technology, which is applied in the field of polyester filament production and processing, can solve the problems of poor performance of polyester POY filament, achieve process stability, improve utilization rate, and realize the effect of economic cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

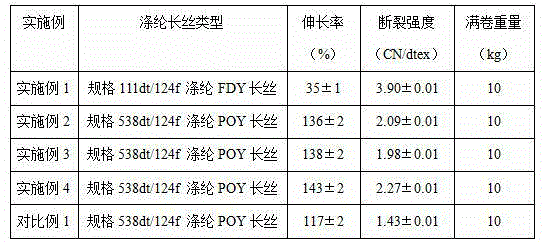

Examples

Embodiment 1

[0028] Embodiment 1, the method of utilizing polyester waste silk industrial production specification 111dt / 124f polyester FDY filament

[0029] (1) Preparation of foam material: Wash and dry the waste silk, cut off the fibers with a length of 8-12mm, use the foam material manufacturing machine to generate heat through mechanical friction to soften and bond the fibers into large granules, Then it is poured into water, and it bursts into small particles to obtain small particles, which is the foam material; the foam material is granular and irregular in shape, with a viscosity of 0.625dl / g, a melting point of 249.8°C, and an external moisture content of 3.0%. , bulk density is 450kg / m 3 .

[0030] (2) Crystallization: Put the foam material obtained in step (1) into the crystallization bed through a rotary valve, and keep boiling. The thickness of the crystallization bed material layer is 20cm, the crystallization time is 60min, and the crystallization temperature is 170°C;

...

Embodiment 2

[0036] Embodiment 2, the method for utilizing polyester waste silk industrial production specification 538dt / 124f polyester POY filament

[0037] (1) Preparation of foam material: Wash and dry the waste silk, cut off the fibers with a length of 8-12mm, use the foam material manufacturing machine to generate heat through mechanical friction to soften and bond the fibers into large granules, Then it is poured into water, and it bursts into small particles to obtain small particles, which is the foam material; the foam material is granular and irregular in shape, with a viscosity of 0.628dl / g, a melting point of 250.0°C, and an external moisture content of 4.0%. , bulk density is 448kg / m 3 .

[0038] (2) Crystallization: Put the foam material prepared in step (1) into the crystallization bed through a rotary valve, and keep boiling. The thickness of the crystallization bed material layer is 15cm, the crystallization time is 50min, and the crystallization temperature is 175°C; ...

Embodiment 3

[0044] Embodiment 3, the method for utilizing polyester waste silk industrial production specification 538dt / 124f polyester POY filament

[0045] (1) Preparation of foam material: Wash and dry the waste silk, cut off the fibers with a length of 8-12mm, use the foam material manufacturing machine to generate heat through mechanical friction to soften and bond the fibers into large granules, Then it is poured into water, and it bursts into small particles to obtain small particles, which is the foam material; the foam material is granular and irregular in shape, with a viscosity of 0.623dl / g, a melting point of 249.6°C, and an external moisture content of 2.0%. , bulk density is 452kg / m 3 .

[0046] (2) Crystallization: Put the foam material prepared in step (1) into the crystallization bed through a rotary valve, and keep boiling. The thickness of the crystallization bed material layer is 18cm, the crystallization time is 55min, and the crystallization temperature is 165°C; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com