Anticorrosion structure and treatment method of outer bottom edge board of gas chamber

A bottom edge, gas cabinet technology, which is applied to building components, large-capacity bulk material storage, building insulation materials, etc. The effect of wide range, good containment and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

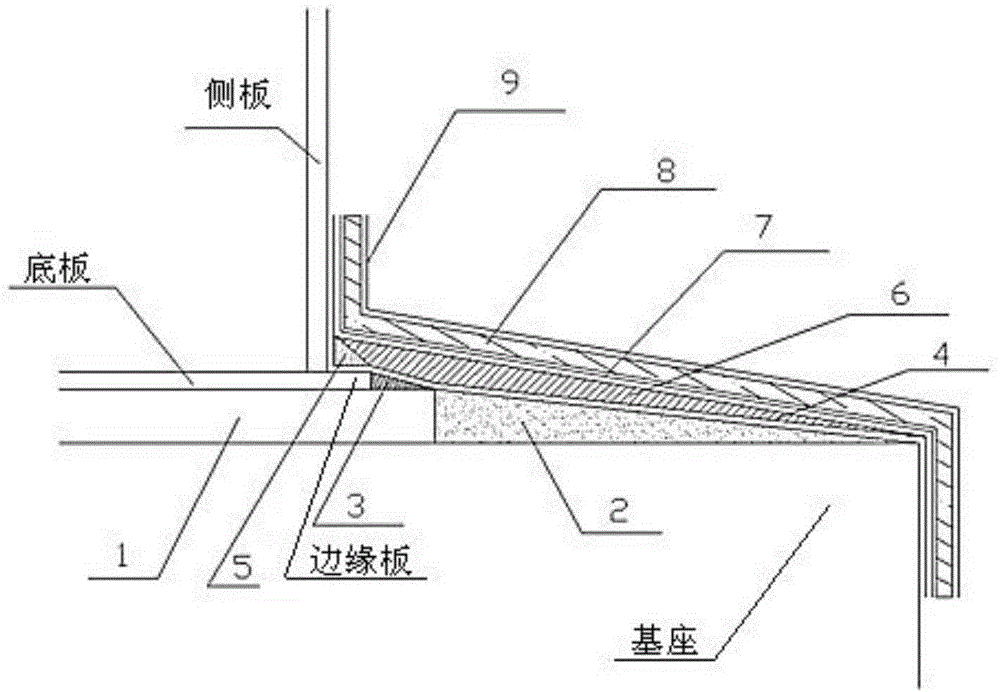

[0049] Embodiment 1 provided by the present invention is an embodiment of the anti-corrosion structure of the outer bottom edge plate of the gas cabinet provided by the present invention. Such as figure 1 Shown is a schematic cross-sectional view of an anti-corrosion structure of a gas cabinet outer bottom edge plate provided by the present invention, by figure 1 It can be seen that there is an asphalt mortar layer 1 between the bottom plate of the gas cabinet and the base, and the radius length of the asphalt mortar layer 1 is greater than that of the bottom plate and extends to the outside of the edge plate.

[0050] Between the upper end point on the outer side of the asphalt mortar layer 1 and the edge of the base, there are cement mortar water slopes 2 with successively decreasing thicknesses.

[0051] An antiseptic 3 is filled between the upper end point on the outer side of the edge board and the upper end point on the outer side of the asphalt mortar layer 1 .

[005...

Embodiment 2

[0065] Embodiment 2 provided by the present invention is an embodiment of an anti-corrosion treatment method for the outer bottom edge plate of a gas cabinet provided by the present invention, including:

[0066] Step 1, determine the outside of the gas cabinet, the distance x from the bottom of the side plate of the gas cabinet to the distance y below the outside of the base is the anti-corrosion area of the outer bottom edge plate of the gas cabinet.

[0067] Step 2: In the area between the upper end point on the outer side of the asphalt sand cushion layer 1 and the edge of the base, a cement mortar water slope 2 with decreasing thickness is made, and the surface of the cement mortar water slope 2 is smoothed and dried.

[0068] Step 3, filling the preservative 3 between the upper end point on the outer side of the edge board and the upper end point on the outer side of the asphalt mortar layer 1 .

[0069] Step 4, in the anti-corrosion area, paint the first elastic polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com