Throttle body

A throttle body and throttle valve technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of poor manufacturability, heavy structure, low integration, etc., and achieve improved assembly manufacturability, good production manufacturability, Good installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

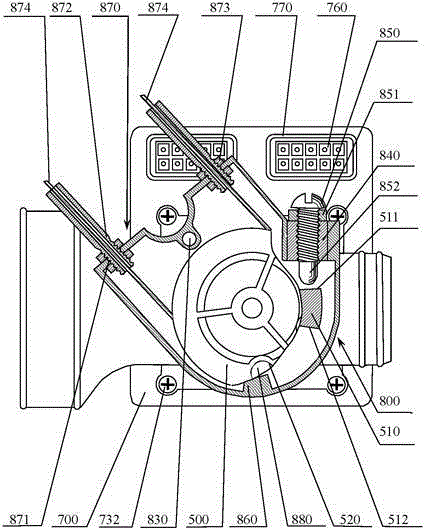

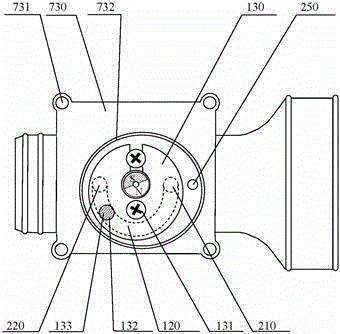

[0035] Such as figure 1 and figure 2 As shown, the throttle body of the present invention includes: a throttle body 100, an air intake passage 200 is arranged inside the throttle body 100; a throttle shaft 300 vertically arranged with the intake passage 200, the throttle shaft 300 passes through a 110 is connected with the throttle body 100; there is a gap in the middle of the throttle shaft 300, and the throttle plate 400 is embedded in it, and two screws 310 fix the throttle plate 400 and the throttle shaft 300 as one; and the return spring 600 acting on the throttle shaft 300, the return spring 600 acts on the throttle shaft 300, so that the throttle shaft 300 is always subjected to the reset force of the rotation to the idle opening.

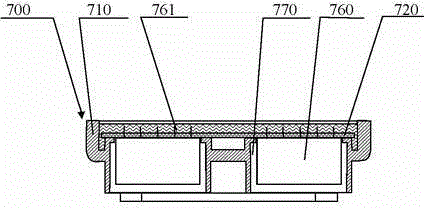

[0036] An electric control unit 700 is arranged on the side of the throttle body 100. The electric control unit 700 includes an electric control unit housing 710 and a circuit board 720 for engine control. The electric control unit housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com