A kind of processing method of rock tea and greening machine used in greening process thereof

A processing method and technology of rock tea, applied in the field of greening machines, can solve the problems of difficult control of the temperature of the greening machine, affecting the quality of rock tea, and low yield of rock tea, so as to shorten the withering time, enhance the water absorption rate of cells, The effect of improving fragrance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

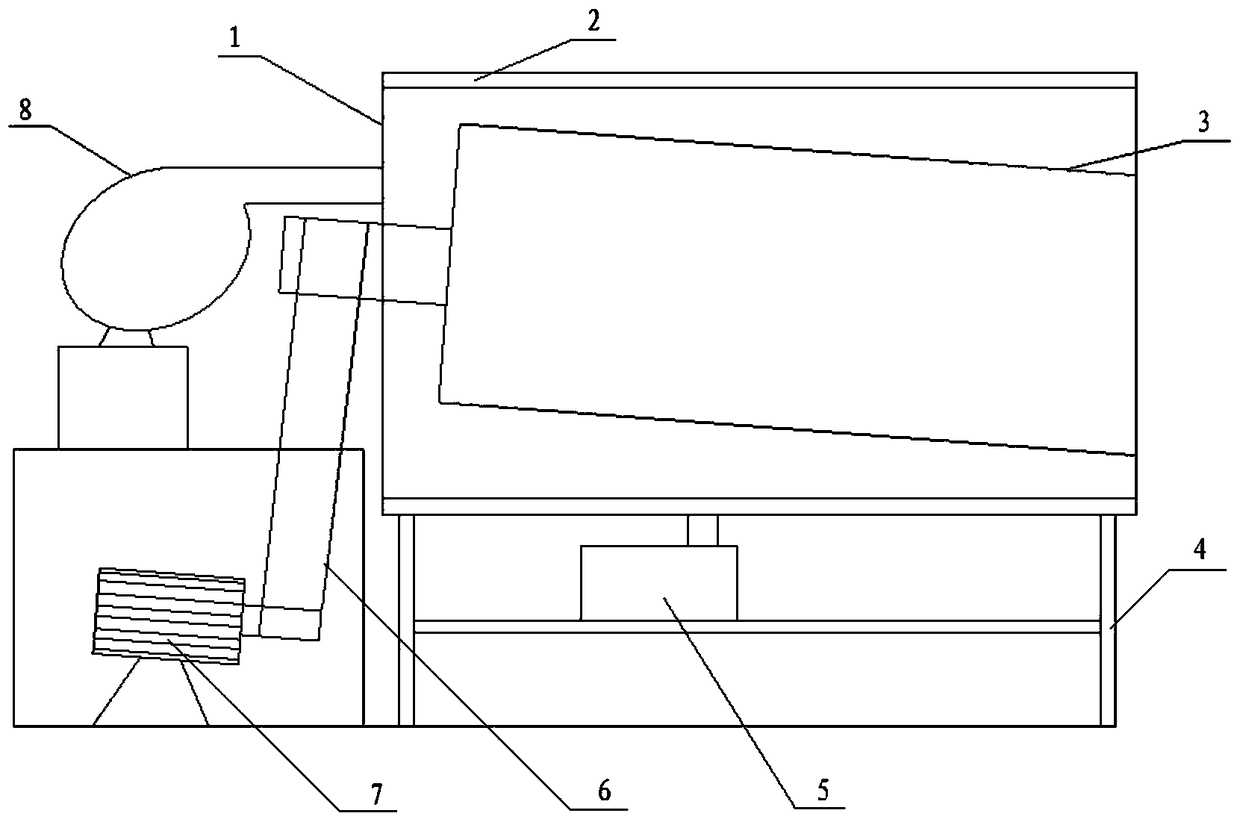

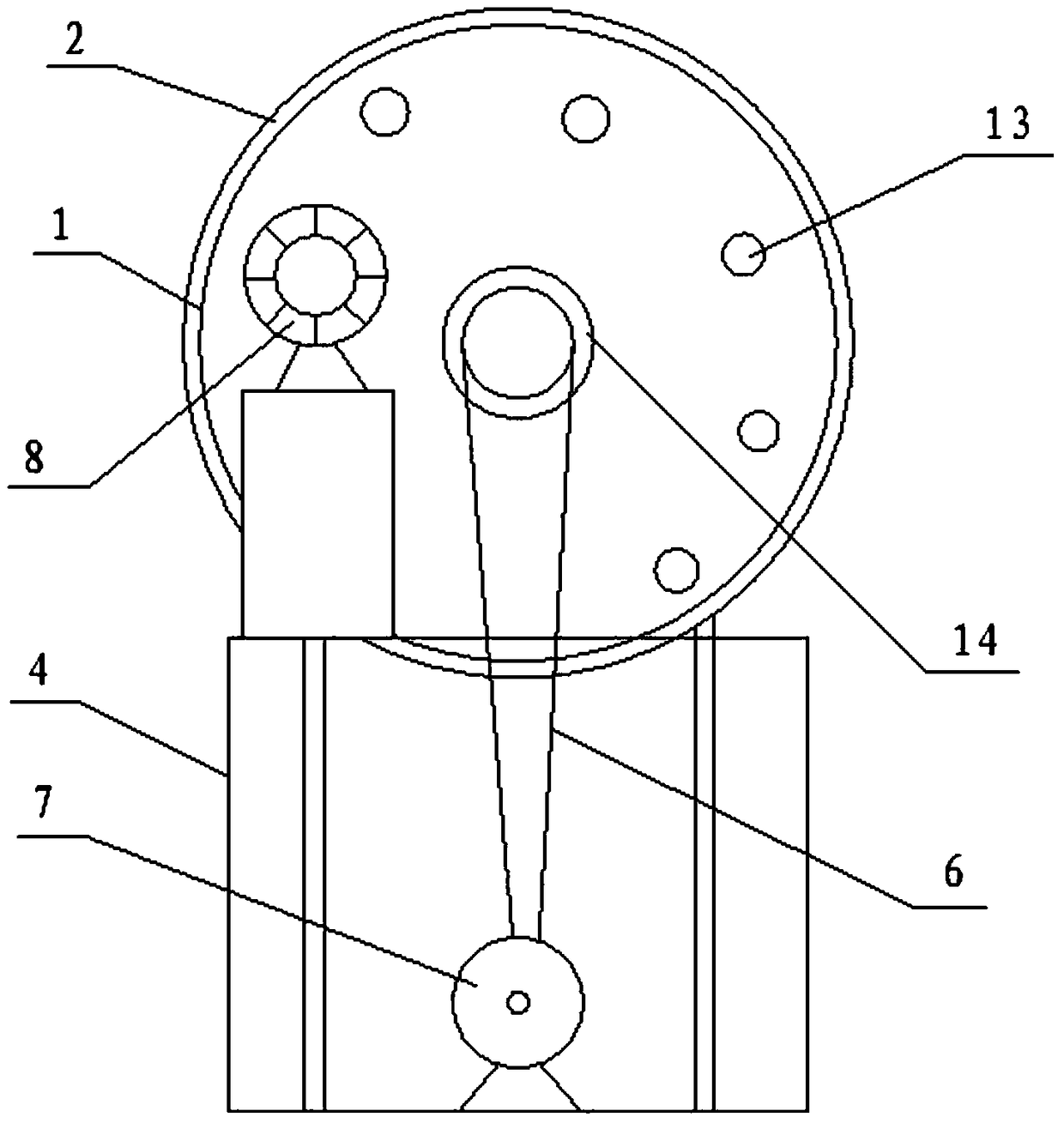

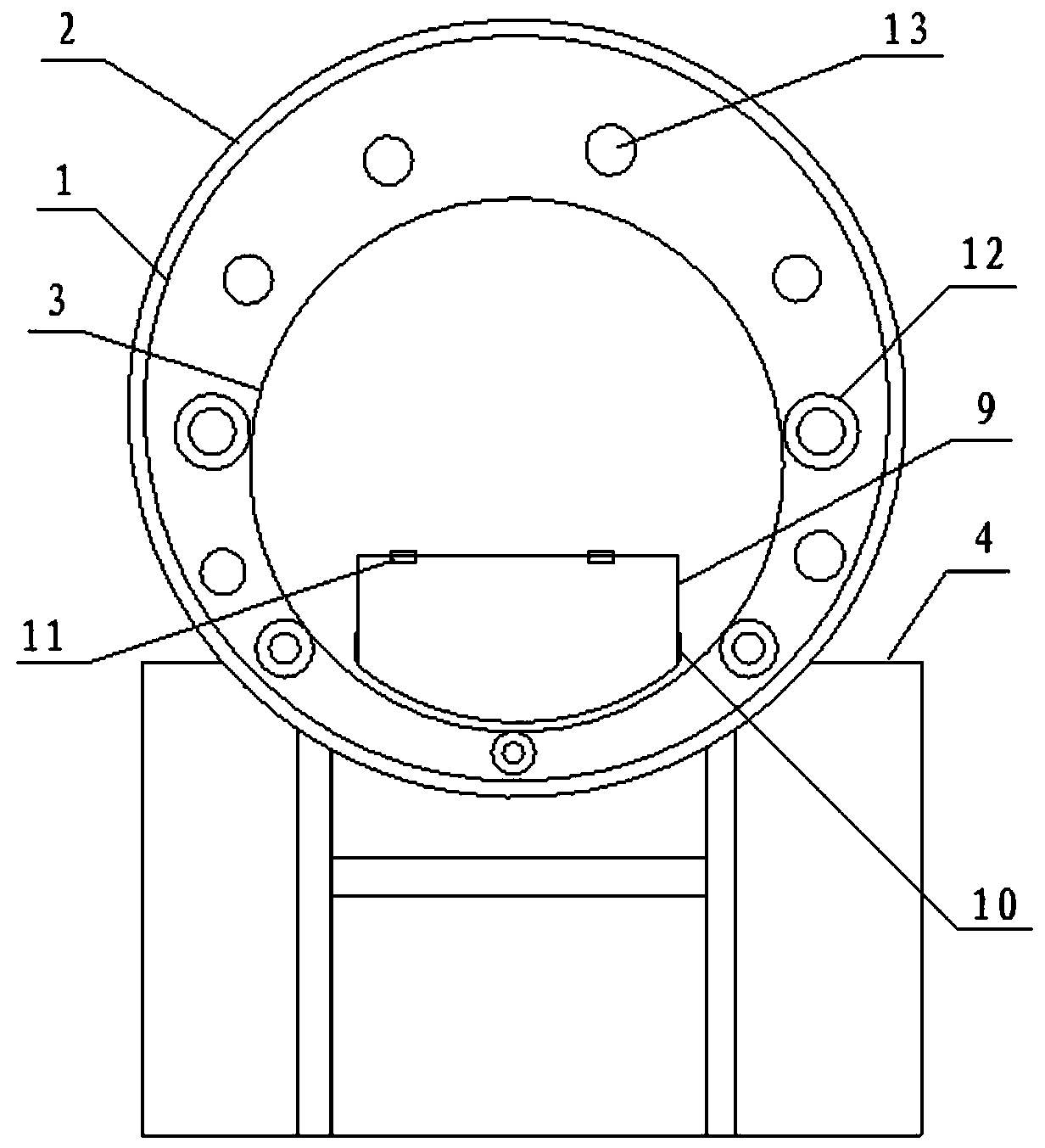

[0038] Such as figure 1 , figure 2 and image 3 As shown, in the greening machine used in the greening process of the processing method of rock tea, the fixed cylinder 1 is welded on the frame 4, and the frame 4 is provided with a blower 8, and the air outlet of the blower 8 is installed on the bottom of the fixed cylinder 1. On one side, cold air or hot air is blown into the fixed cylinder by a blower to adjust the temperature in the fixed cylinder 1 . A bearing 14 is installed on the side of the fixed cylinder 1 close to the motor 7, and several rollers 12 are installed on the other side. A high temperature resistant rubber sleeve is installed between the rotating drum 3 and the fixed drum 1 at the back, forming a closed space between the rotating drum 3 and the fixed drum 1 . The water cover 2 is wrapped on the outer surface of the fixed cylinder 1, an electric heater 5 is arranged in the frame 4 below the fixed cylinder 1, and the electric heater 5 is connected with th...

Embodiment 2

[0040] A processing method of rock tea, comprising the following steps:

[0041] (1) Picking: When the tea tree germinates in spring every year, fresh leaves with one bud and three leaves are manually picked to ensure the integrity and uniformity of the fresh leaves, and they are not picked in rainy days or hot days;

[0042] (2) Withering: adjust the temperature in the withering machine to be 25°C and the humidity to be 60%, put the fresh rock tea leaves into the withering machine, and the withering time is 60min to obtain withered leaves with a moisture content of 73%;

[0043] (3) Greening: Repeat 5 times according to the program of shaking green → blowing → standing. In the drum-type greening machine, shake green at a speed of 20r / min for 7 minutes, then take out the withered leaves, and use a blower to blow air in the withered leaves for 30 minutes, and then adjust the temperature of the standing room to 24°C , the humidity is 70%, and the withered leaves are sent to the...

Embodiment 3

[0051] A processing method of rock tea, comprising the following steps:

[0052] (1) Picking: When the tea tree germinates in spring every year, fresh leaves with one bud and four leaves are manually picked to ensure the integrity and uniformity of the fresh leaves, and they are not picked in rainy days or hot days;

[0053] (2) Withering: adjust the temperature in the withering machine to be 30°C and the humidity to be 70%, put the fresh rock tea leaves into the withering machine, and the withering time is 70min to obtain withered leaves with a moisture content of 68%;

[0054](3) Greening: Repeat 6 times according to the program of shaking green → blowing → standing. In the drum-type greening machine, shake green at a speed of 24r / min for 7 minutes, then take out the withered leaves, and use a blower to blow air in the withered leaves for 35 minutes, and then adjust the temperature of the standing room to 26°C , the humidity is 80%, and the withered leaves are sent to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com