Production process of double-layer thermal insulation glass cup

A technology of double-layer heat preservation and production technology, which is applied in the direction of drinking water containers, etc., can solve the problems of double-layer glass finished products bursting or cracking, waste of manpower, material resources, financial resources, and cumbersome production technology, so as to reduce the probability of bursting and reduce the production The effect of short cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

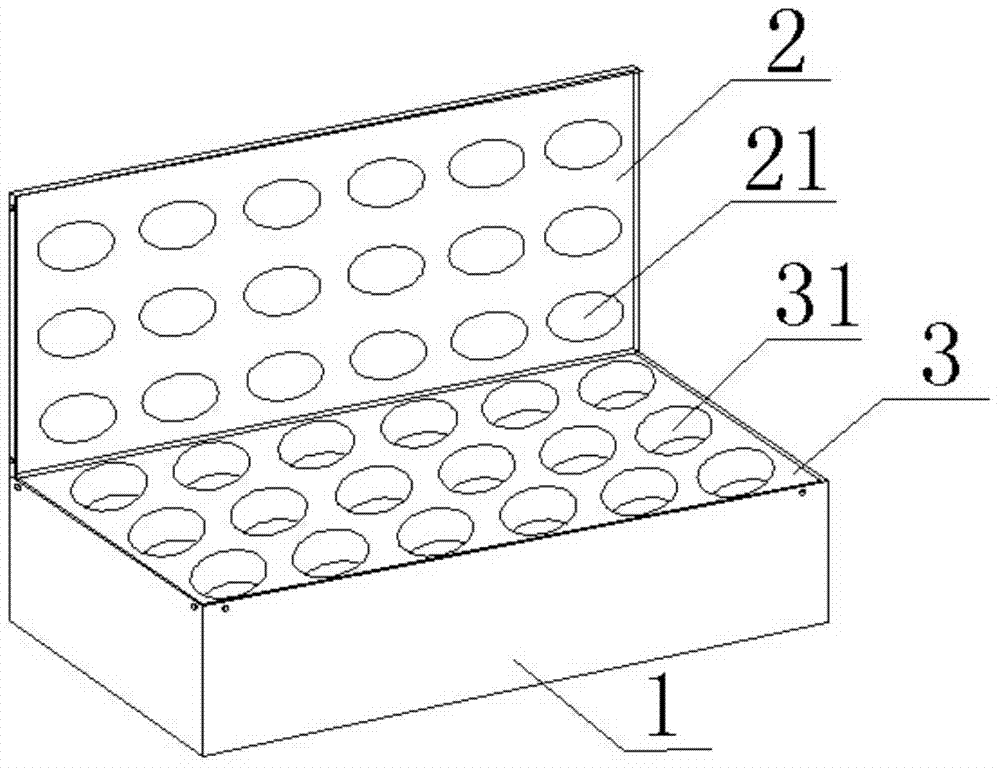

Image

Examples

Embodiment 1

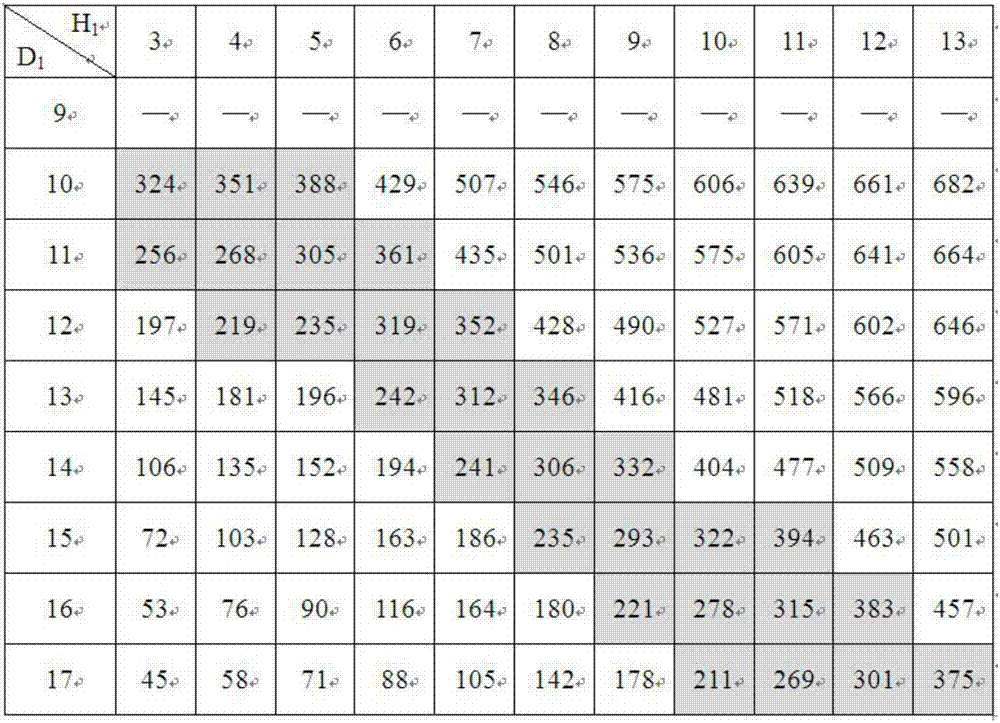

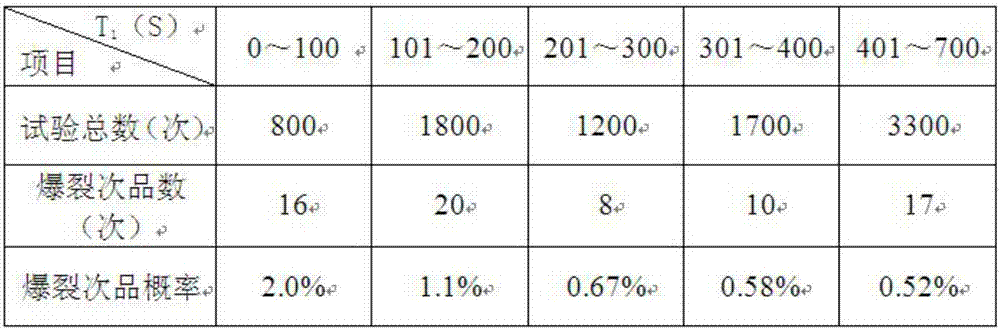

[0043] Taking the outer cup diameter of 10cm of the high-temperature double-layer glass as an example, the cylindrical concave hole 31 of the incubator has a diameter of D 1 Set 14cm, cylindrical concave hole 31 depth H 1 Set 7cm. After cutting, bottom pulling, pressing, sealing and heat preservation for 201~400S, then testing, assembly and packaging. Ensure that other external conditions are the same, repeat production 1000 times, and the probability of defective products such as bursts and cracks in the finished high-temperature double-layer glass is 0.68%.

Embodiment 2

[0045] Taking the outer cup diameter of 10cm of the high-temperature double-layer glass as an example, the cylindrical concave hole 31 of the incubator has a diameter of D 1 Set 14cm, cylindrical concave hole 31 depth H 1 Set 9cm. After cutting, bottom pulling, pressing, sealing and heat preservation for 201~400S, then testing, assembly and packaging. Ensure that other external conditions are the same, repeat production 1,000 times, and the probability of defective products such as bursts and cracks in the finished high-temperature double-layer glass is 0.59%.

Embodiment 3

[0047] Taking the high-temperature double-layer glass outer cup diameter 12cm as an example, the cylindrical concave hole 31 of the incubator has a diameter of D 1 Set 17cm, cylindrical concave hole 31 depth H 1 The setting is 8cm; the finished high-temperature double-layer glass after sealing is inverted and placed in an incubator. After heat preservation for 201-400 seconds, the temperature of the finished double-layer glass drops below 60°C. Ensure that other external conditions are the same, repeat production 1000 times, and the probability of defective products such as bursts and cracks in the finished high-temperature double-layer glass is 0.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com