Oriented particle board with ultrathin particles on surface layer, and preparation process thereof

A technology of oriented particle board and preparation process, which is applied in the direction of manufacturing tools, flat products, and other household appliances, etc. It can solve the problems that the mechanical properties of the board cannot be improved at the same time, the elastic modulus and internal bonding strength are low, and the surface is uneven, etc., to achieve improved The effect of overall mechanical properties, small density deviation and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

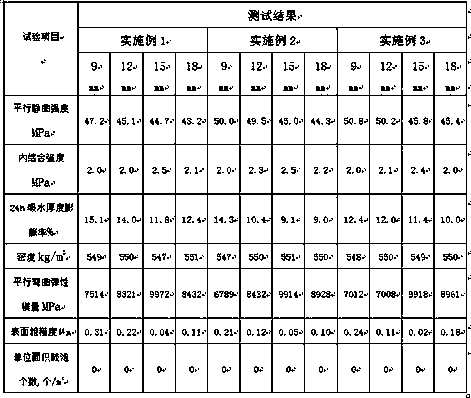

Examples

Embodiment 1

[0038] Embodiment 1 A kind of surface layer is the oriented strand board and its preparation process of ultra-thin large shavings

[0039] A surface layer of the present invention is an oriented strand board with ultra-thin large flakes of shavings, and its preparation process comprises the following steps: preparation of core layer and subsurface shavings, preparation of surface shavings, raw material drying, raw material screening, sizing, paving, heating pressure and post-processing. details as follows:

[0040] (1) Preparation of core and subsurface shavings:

[0041] The shavings of the core layer and the sub-surface layer are made of rotary-cut waste veneer, branch wood, slab, etc., which are sawn and then passed through a ring planer to make shavings with a length of 60-120 mm, a width of 5-40 mm, and a thickness of 0.5-1.0 mm. , transported to wet shavings silo for storage.

[0042] (2) Preparation of surface shavings:

[0043] The surface shavings are made of smal...

Embodiment 2

[0067] Embodiment 2 A kind of surface layer is the oriented strand board and its preparation process of ultra-thin large shavings

[0068] A surface layer of the present invention is an oriented strand board with ultra-thin large flakes of shavings, and its preparation process comprises the following steps: preparation of core layer and subsurface shavings, preparation of surface shavings, raw material drying, raw material screening, sizing, paving, heating pressure and post-processing. details as follows:

[0069] (1) Preparation of core and subsurface shavings:

[0070] The shavings of the core layer and the sub-surface layer are made of rotary-cut waste veneer, branch wood, slab, etc., which are sawn and then passed through a ring planer to make shavings with a length of 60-120 mm, a width of 5-40 mm, and a thickness of 0.5-1.0 mm. , transported to wet shavings silo for storage.

[0071] (2) Preparation of surface shavings:

[0072] The surface shavings are made of smal...

Embodiment 3

[0096] Embodiment 3 A kind of surface layer is the oriented strand board and its preparation process of ultra-thin large shavings

[0097] A surface layer of the present invention is an oriented strand board with ultra-thin large flakes of shavings, and its preparation process comprises the following steps: preparation of core layer and subsurface shavings, preparation of surface shavings, raw material drying, raw material screening, sizing, paving, heating pressure and post-processing. details as follows:

[0098] (1) Preparation of core and subsurface shavings:

[0099] The shavings of the core layer and the sub-surface layer are made of rotary-cut waste veneer, branch wood, slab, etc., which are sawn and then passed through a ring planer to make shavings with a length of 60-120 mm, a width of 5-40 mm, and a thickness of 0.5-1.0 mm. , transported to wet shavings silo for storage.

[0100] (2) Preparation of surface shavings:

[0101] The surface shavings are made of smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com