Coal liquefaction catalyst and preparation method and application thereof

A catalyst, coal liquefaction technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the limitations of catalyst overall activity and particle size stability, catalyst activity reduction, small specific surface area, etc. problem, to achieve the effect of adjustable carrier particle size range, less usage and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of coal liquefaction catalyst of the present invention comprises the following steps:

[0028] 1) Water configuration ferrous salt solution, wherein ferrous ion Fe 2+ The concentration is: 0.05mol / L~1.5mol / L, add 50~95wt% carrier of the catalyst to be synthesized into the prepared ferrous salt solution and stir evenly to form solution A;

[0029] 2) Pass excessive air or oxygen into the above solution A, add alkali solution and stir evenly, control the pH of the reaction process by adding the content of alkali solution at 5.0-6.9, react for 0.5-4 hours, and the reaction temperature is 20-50 degrees Celsius ; The alkaline solution is a strong base or a weak base containing hydroxide ions;

[0030] 3) After the reaction is completed, the material is discharged, dehydrated and dried to obtain a supported catalyst whose active component is elongated α-FeOOH.

[0031] The present invention proposes the application of the coal liquefaction catalyst: t...

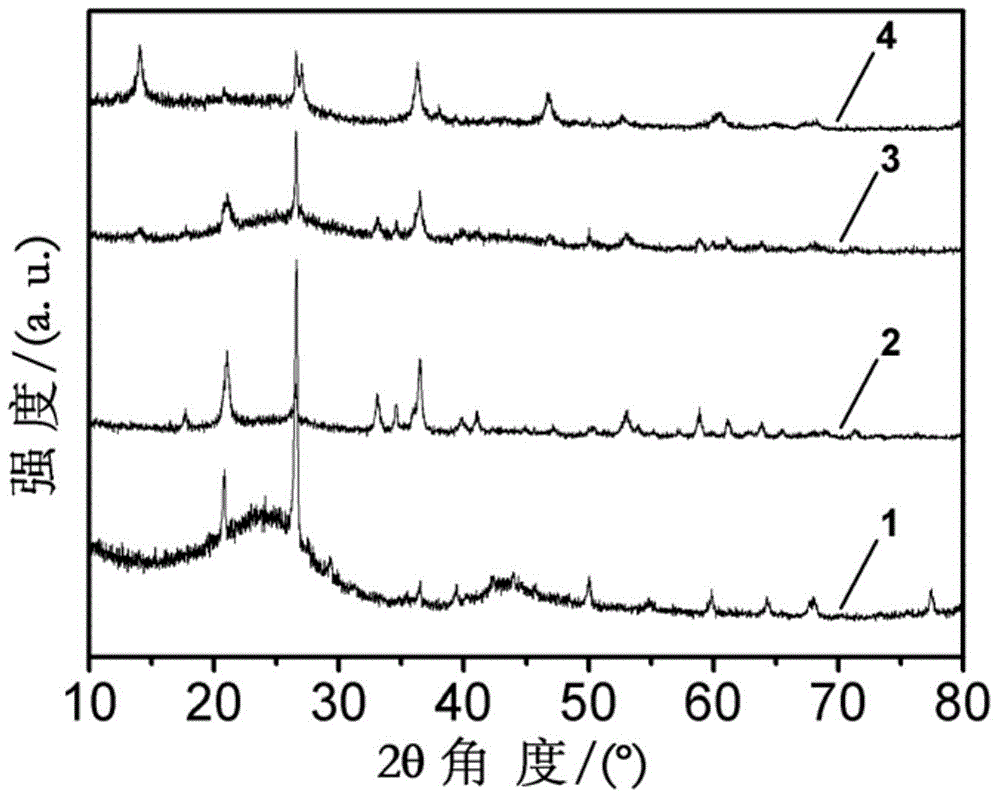

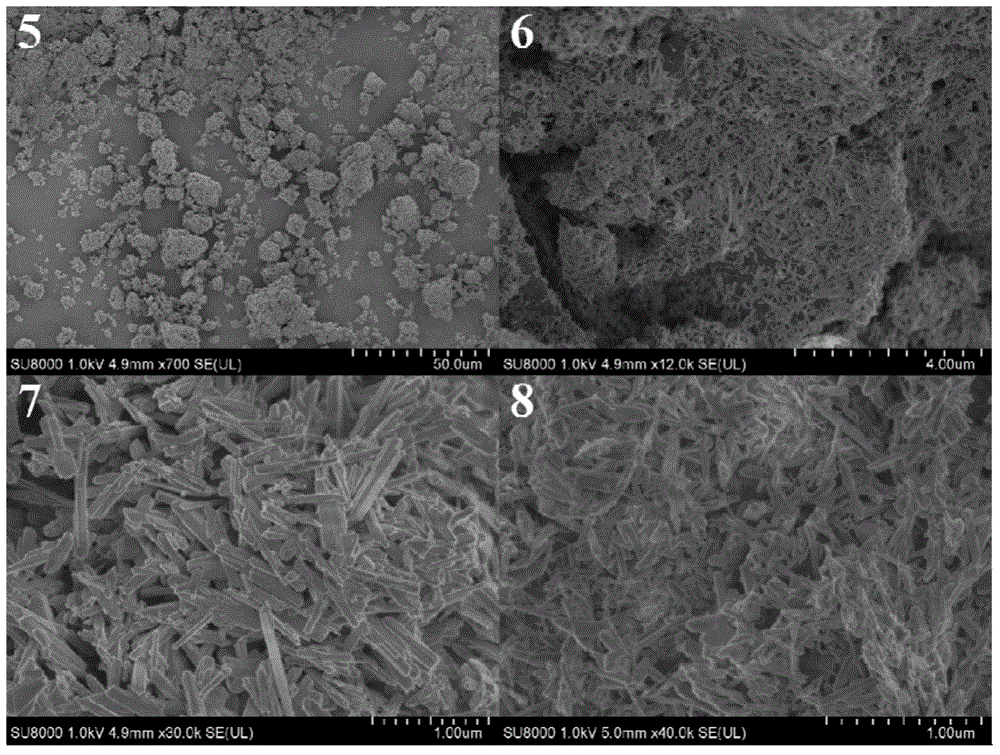

Embodiment 1

[0034] Prepare a ferrous sulfate salt solution with a concentration of 0.2mol / L with water, and add 5.34g of carrier to the salt solution; 3 Oxygen per hour, while gradually adding ammonia solution with a concentration of 1mol / L, controlling its pH at 6.0-7.0, reacting for 1.5 hours, and the reaction temperature is 38 degrees Celsius. Subsequent discharge, suction filtration and drying in a constant temperature drying oven at 100 degrees Celsius, to obtain the catalyst α-FeOOH / carrier of the present invention that is 20wt% with Fe metering load, the XRD of this catalyst is as follows figure 1 As shown, the SEM photos are as figure 2 shown.

Embodiment 2

[0036] Add 0.5 kg of ferrous sulfate heptahydrate to 10 kg of water, and add 2.88 kg of carrier, the flow rate is 2m 3 / h of air, while constantly adding 0.5 kg of 25wt% ammonia. React for 1.5 hours, and the reaction temperature is 25 degrees Celsius. Subsequent discharge, dehydration and drying at 100 degrees to obtain the catalyst α-FeOOH / carrier of the present invention with a Fe metering load of 5wt%, the XRD of the catalyst is as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com