Sponge abrasive paper and manufacturing method of same

A technology of sponge sandpaper and manufacturing method, which is applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of inability to polish and polish the equipment, the abrasives are easy to fall off and damage, and are not durable, so as to meet the overall consistent design requirements and improve the surface smoothness. The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

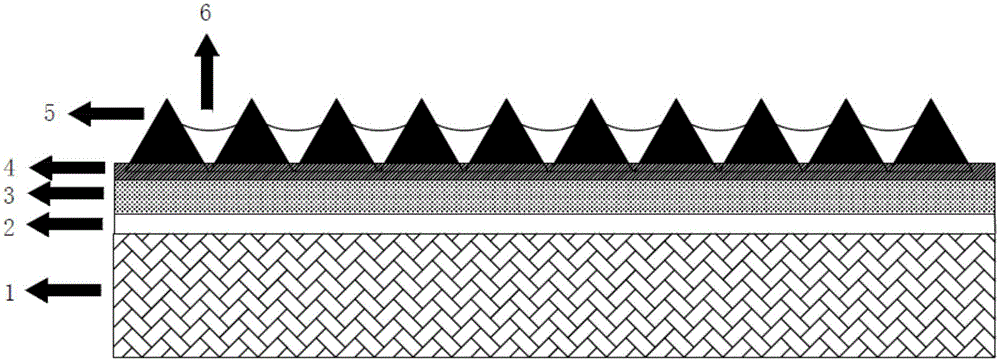

[0030] Such as figure 1 As shown, the present embodiment proposes a kind of sponge sandpaper, comprises sponge layer 1, bonding glue layer 2, primer layer 4, abrasive material layer 5 and compound glue layer 6, also comprises polyurethane film layer 3, and polyurethane film layer 3 passes through at least One layer of bonding adhesive layer 2 is bonded on the sponge layer 1, and the abrasive layer 5 is bonded on the polyurethane film layer 3 through at least one primer layer 4 and at least one layer of adhesive layer 6 covering the primer layer 4 .

[0031] In this embodiment, the abrasive material layer 5 is a silicon carbide layer, a brown corundum layer, a zirconium corundum layer, a white corundum layer or a quartz sand layer.

Embodiment 2

[0033] Such as figure 1 Shown, the manufacture method of sponge sandpaper of the present invention comprises the following processing steps:

[0034] (1) coating a layer of primer on one side of the polyurethane film, the parts by weight of the primer consist of: 100 parts of adhesive, 30 parts of curing agent, 20 parts of diluent, 20 parts of filler;

[0035] (2) Carry out sand planting on the primer, and choose electrostatic sand planting as the sand planting method;

[0036] (3) Dry the polyurethane film after electrostatic sand planting, and the drying method is to hang it in a drying room at 80°C for 0.5 hours;

[0037] (iv) Apply a layer of compound glue on the bottom glue dried after sand planting, the weight part of the compound glue is composed of: 100 parts of adhesive, 20 parts of diluent, 20 parts of filler;

[0038] (5) Curing the polyurethane film coated with glue, the curing method is to hang it in a drying room at 80°C for 1 hour;

[0039] (vi) The other si...

Embodiment 3

[0042] Such as figure 1 Shown, the manufacture method of sponge sandpaper of the present invention comprises the following processing steps:

[0043] (1) coating a layer of primer on one side of the polyurethane film, the parts by weight of the primer consist of: 100 parts of adhesive, 30 parts of curing agent, 30 parts of diluent, 30 parts of filler;

[0044] (2) Carry out sand planting on the primer, and choose electrostatic sand planting as the sand planting method;

[0045] (3) Dry the polyurethane film after electrostatic sand planting, and the drying method is to hang it in a drying room at 90°C for 0.75 hours;

[0046] (iv) Apply a layer of compound glue on the bottom glue dried after sand planting, the weight part of the compound glue is composed of: 100 parts of adhesive, 50 parts of diluent, and 50 parts of filler;

[0047] (5) Curing the polyurethane film coated with glue, the curing method is to hang it in a drying room at 90°C for 1.5 hours;

[0048] (vi) Coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com