Dynamic membrane bioreactor regulating and control method and device based on surface constant potential control

A bioreactor and control device technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of high energy consumption in aerobic MBR operation, unsatisfactory promotion and application, and MBR process investment Advanced problems, to achieve the effect of reducing dynamic membrane fouling, shortening the required time, and prolonging the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

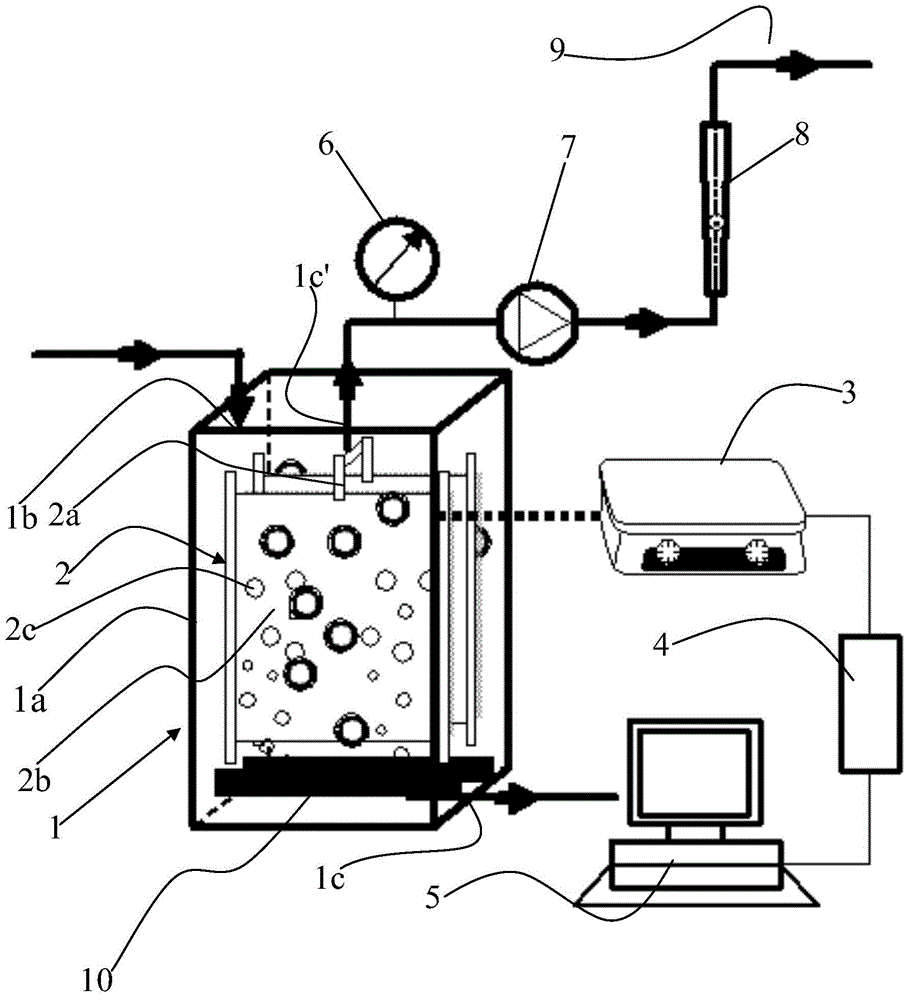

example 1

[0055] Anaerobic DMBR is used to treat cold rolling wastewater. The membrane modules are in the form of flat membranes. The influent COD concentration is 1587±256.4mg / L, the effluent COD concentration is 225±20.5mg / L, and the average removal rate is 92.1%. During the operation, the concentration of mixed liquor sludge is 13g / L, the Zeta potential of anaerobic sludge is -60mV, and the dynamic membrane surface potential is controlled to be -100mV. The operating flux is 20L / m 2 h.

example 2

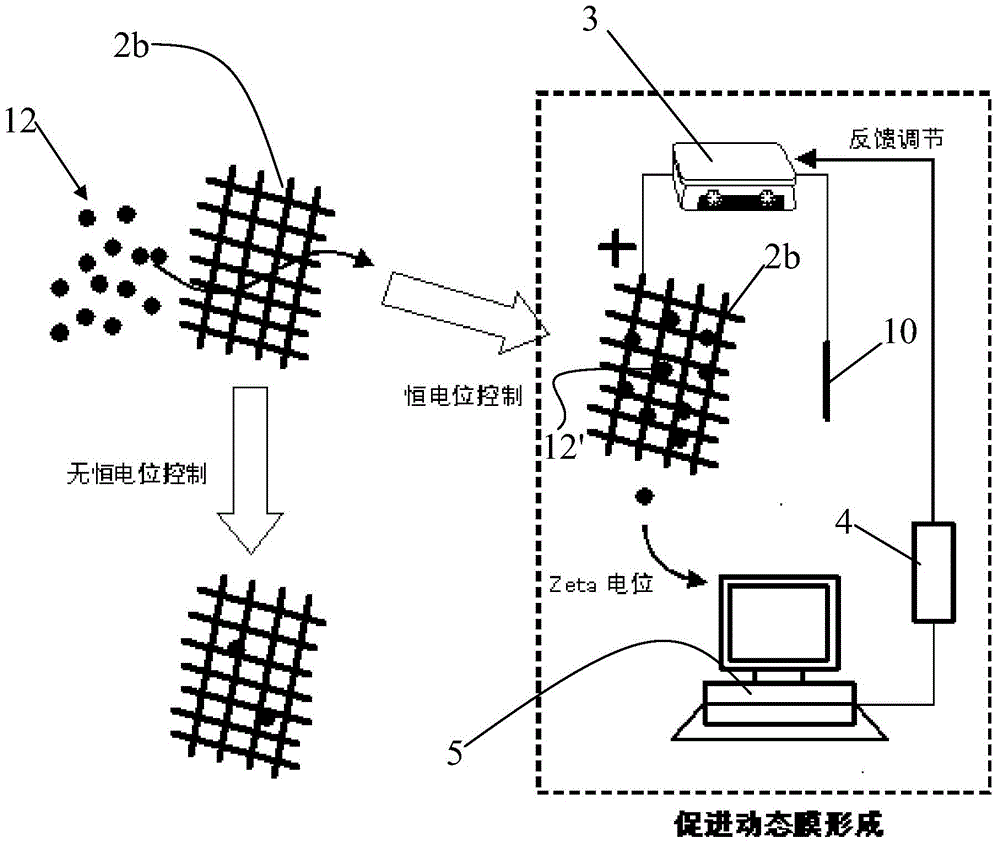

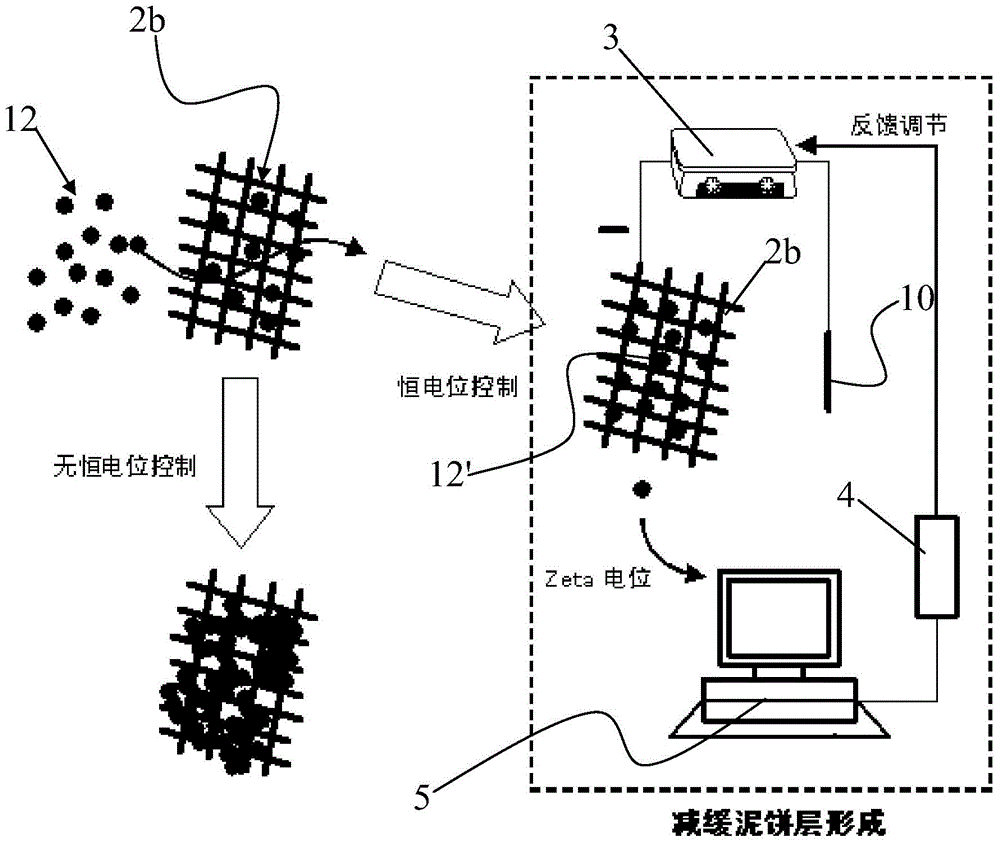

[0057] Aerobic DMBR is used to treat coking sewage, and the membrane module adopts 380 mesh stainless steel wire mesh. Reactor sludge concentration MLSS=4.5g / L, membrane module operating flux 20L / m 2 h, the activated sludge Zeta potential is -10mV during operation. The influent COD concentration is 286.0±71.2mg / L. During the start-up stage of the dynamic membrane bioreactor, a constant potential of +30mV is applied on the membrane surface, and the suspended solids (SS) in the effluent of the reactor will drop below 10mg / L within 20 minutes. The average concentration of COD in the effluent of DMBR in stable operation is 25±5mg / L, and a constant potential of ‐30mV is applied to the membrane surface. In the control group, constant potential control was not applied during the start-up and stabilization phases of the reactor, and the SS dropped below 10 mg / L after 2 hours of effluent from the reactor.

example 3

[0059] The membrane module uses 250-mesh stainless steel wire mesh to construct a DMBR to treat an industrial wastewater. The COD concentration of the influent water is 386±82mg / L, and the ammonia nitrogen concentration is 34±8mg / L. A constant potential of -80 mV was applied to the membrane surface. DMBR sludge concentration MLSS=8g / L, membrane module operating flux 20L / m 2 h. The average concentration of COD in DMBR stable operation water is 20±4.3mg / L, and the concentration of ammonia nitrogen is less than 1.0mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com