Multiferroic compound and preparation method thereof

A multiferroic and compound technology, which is applied in the field of new multifunctional materials, can solve the problems of large leakage current, easy penetration, and no strong magnetoelectric coupling of materials, and achieves a simple and fast preparation method, high yield, The effect of cheap and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 prepares the method for novel single-phase multiferroic compound

[0035] At room temperature, add 2 millimoles of 4-phenylbutylamine, 1 millimole of copper chloride and 0.2 milliliters of 37% (mass) hydrochloric acid into 10 milliliters of water and stir, and slowly evaporate the solvent to obtain yellow flaky crystals with a yield of 96.5 %. The purity is characterized by elemental analysis, calculated C: 47.44%, H: 6.52%, N: 5.62%; test results C: 47.49%, H: 6.38%, N: 5.54%.

Embodiment 2

[0036] Embodiment 2 prepares the method for novel single-phase multiferroic compound

[0037] At room temperature, add 2 mmoles of 4-phenylbutylamine to 10 milliliters of ethanol, add 0.2 milliliters of concentrated hydrochloric acid dropwise under stirring, heat and boil to evaporate most of the solvent, and cool to obtain 4-phenylbutylamine hydrochloride. Add 4-phenylbutylamine hydrochloride and copper chloride at a ratio of 2:1 to ethanol and stir, and evaporate the solvent to obtain a yellow solid with a yield of 97.2%.

Embodiment 3

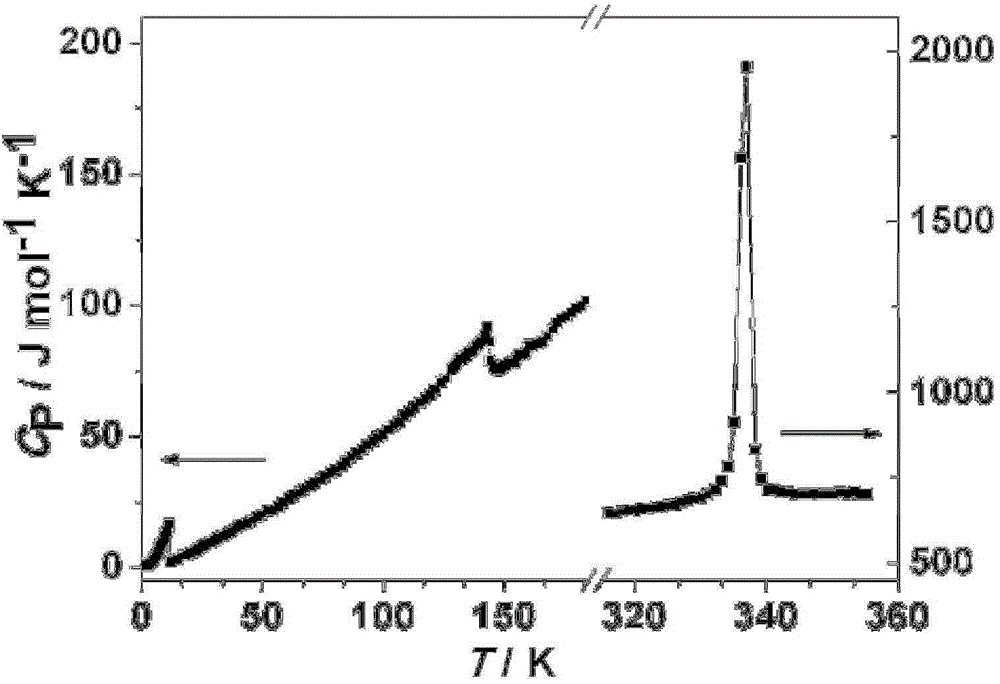

[0038] Embodiment 3 heat capacity test method

[0039] The heat capacity of the compound crystal was tested with Quantum Design's physical property measurement system (PPMS), and the test temperature range was 2-355K. The heat capacity test results show that the compound undergoes a phase transition at 337K, 143K, and 7.5K. The test results are shown in the attached figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com