Material formula and production technology of plastic clip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

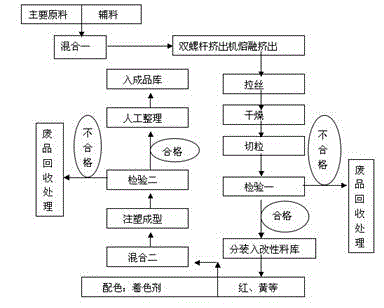

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] see figure 1 , the material formula and production process of the plastic magazine, including main raw materials and auxiliary materials, the main raw materials include 80kg polypropylene and 35kg polyethylene, and the auxiliary materials include 25kg toughening agent, 18.5kg heat stabilizer, 10.5kg low temperature retaining agent , 11kg anti-aging agent and 5kg lubricant, in the present embodiment, described toughening agent is EPDM rubber, heat stabilizer is barium composite stabilizer, low temperature retaining agent is vinyl acetate, lubricant is PE wax.

[0011] The production process of the present invention is as follows: a. uniformly mixing the main raw materials and auxiliary materials in the boiler for the first time; b. adding the mixed main raw materials and auxiliary materials into a twin-screw extruder for melt ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com