Acid-alkali dual response intelligent nano container based anti-corrosion coating preparation method and application

A technology of anti-corrosion coatings and nano-containers, which is applied in the preparation of metal anti-corrosion coatings, anti-corrosion coating preparation field based on acid-base double response smart nano-containers, which can solve the waste of corrosion inhibitors, anti-corrosion coatings do not have acid-base stimulation Response to problems such as controlled release to achieve the effect of extending service life and ensuring persistence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

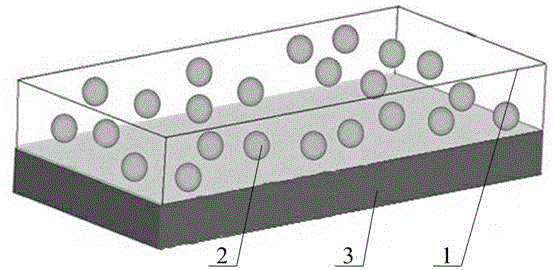

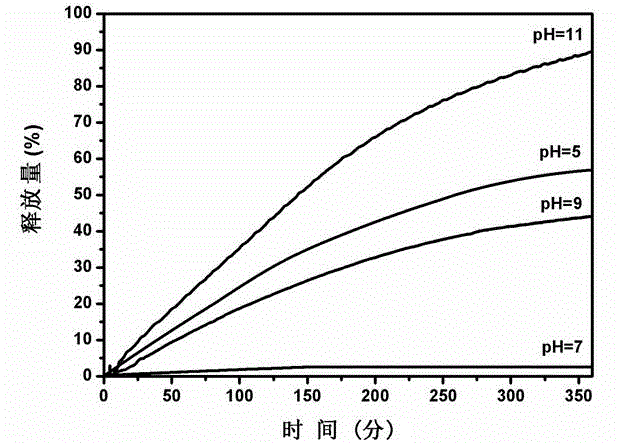

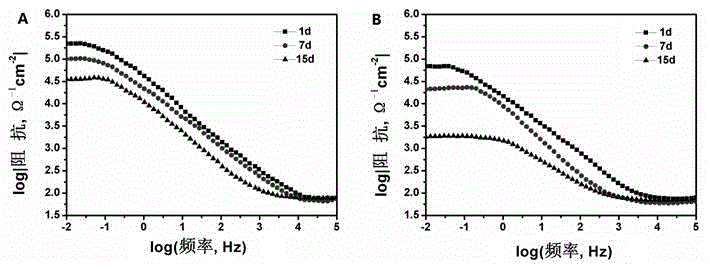

Image

Examples

Embodiment 1

[0034] Step 1, preparing hollow mesoporous silica microspheres.

[0035] 1. Drop 10mL polystyrene aqueous solution (8 wt%) into a mixture containing 0.8g cetyltrimethylammonium bromide (CTAB), 29mL deionized water, 15mL ethanol and 1mL concentrated ammonia water, at room temperature Stir for 15 min.

[0036] 2. Drop 1.38mL tetraethyl orthosilicate (TEOS) into the above mixture within 5min, react for 48h, centrifuge, wash with ethanol, and calcinate the obtained product in a muffle furnace at 550°C 8h.

[0037] 3. Reflux the calcined product in a mixture of 5mL concentrated hydrochloric acid and 100mL ethanol at 60°C for 5h, centrifuge, wash with methanol, and dry under vacuum at 60°C to obtain hollow mesoporous silica microspheres (HMSs).

[0038] Step 2, preparing an acid-base responsive smart nano container.

[0039]1. Disperse 100mg of hollow mesoporous silica microspheres in 15mL of anhydrous toluene, add 100mg of chloromethyltriethoxysilane (CMTES) dropwise under a nit...

Embodiment 2

[0048] Step 1, preparing hollow mesoporous silica microspheres.

[0049] 1. Drop 10mL polystyrene aqueous solution (8 wt%) into a mixture containing 1g cetyltrimethylammonium bromide (CTAB), 29mL deionized water, 15mL ethanol and 1mL concentrated ammonia water, at room temperature Stir for 15min.

[0050] 2. Drop 1.38mL tetraethyl tetrasilicate (TEOS) into the above mixture within 5min, react for 72h, centrifuge, wash with ethanol, and calcinate the obtained product in a muffle furnace at 500°C 6h.

[0051] 3. Reflux the calcined product in a mixture of 5mL concentrated hydrochloric acid and 50mL ethanol at 80°C for 6h, centrifuge, wash with methanol, and dry in vacuum at 60°C to obtain hollow mesoporous silica microspheres (HMSs).

[0052] Step 2, preparing an acid-base responsive smart nano container.

[0053] 1. Disperse 100mg of hollow mesoporous silica microspheres in 15mL of anhydrous toluene, add 120mg of chloromethyltriethoxysilane (CMTES) dropwise under a nitrogen ...

Embodiment 3

[0062] Step 1, preparing hollow mesoporous silica microspheres.

[0063] 1. Drop 10mL polystyrene aqueous solution (10 wt%) into a mixture containing 1g cetyltrimethylammonium bromide (CTAB), 29mL deionized water, 15mL ethanol and 1mL concentrated ammonia water, at room temperature Stir for 15min.

[0064] 2. Drop 1.38mL tetraethyl orthosilicate (TEOS) into the above mixture within 5min, react for 60h, centrifuge, wash with ethanol, and calcinate the obtained product in a muffle furnace at 530°C 7h.

[0065] 3. Reflux the calcined product in a mixture of 5mL concentrated hydrochloric acid and 100mL ethanol at 70°C for 5h, centrifuge, wash with methanol, and dry under vacuum at 60°C to obtain hollow mesoporous silica microspheres (HMSs).

[0066] Step 2, preparing an acid-base responsive smart nano container.

[0067] 1. Disperse 100mg of hollow mesoporous silica microspheres in 15mL of anhydrous toluene, add 80mg of chloromethyltriethoxysilane (CMTES) dropwise under a nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com