Borate scintillating material

A scintillation material, borate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of unstable chemical properties, long decay life, low light yield, etc., to achieve the reaction conditions and requirements of simple equipment, attenuation The effect of short lifetime and high light yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Nitriding doped Ba of the present invention 3 InB 9 o 18 preparation of

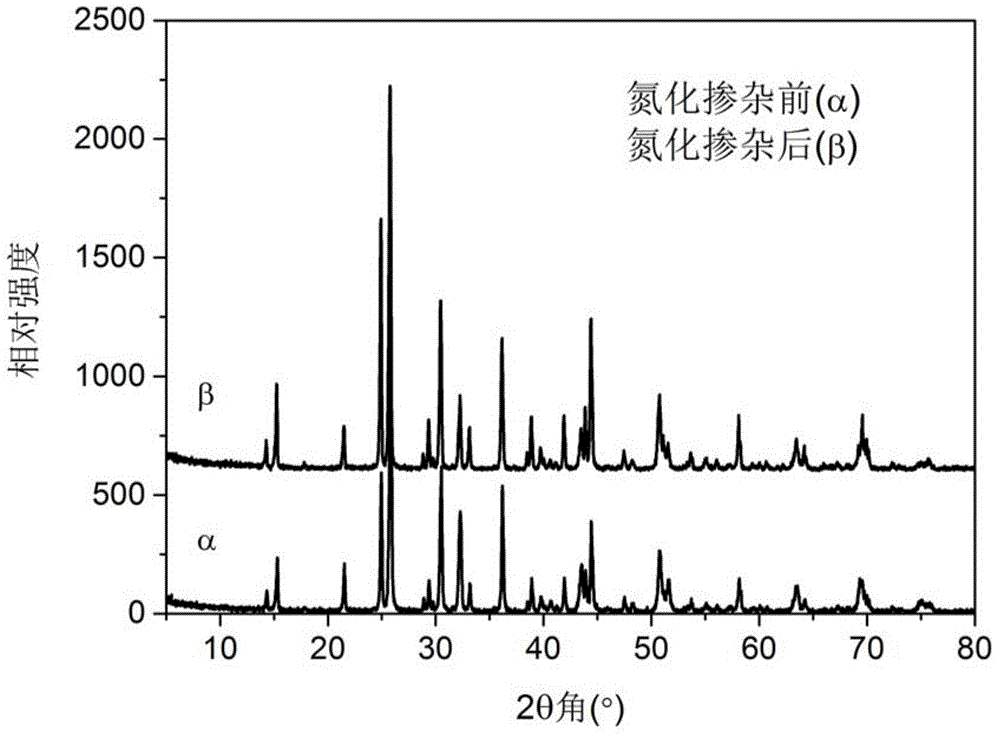

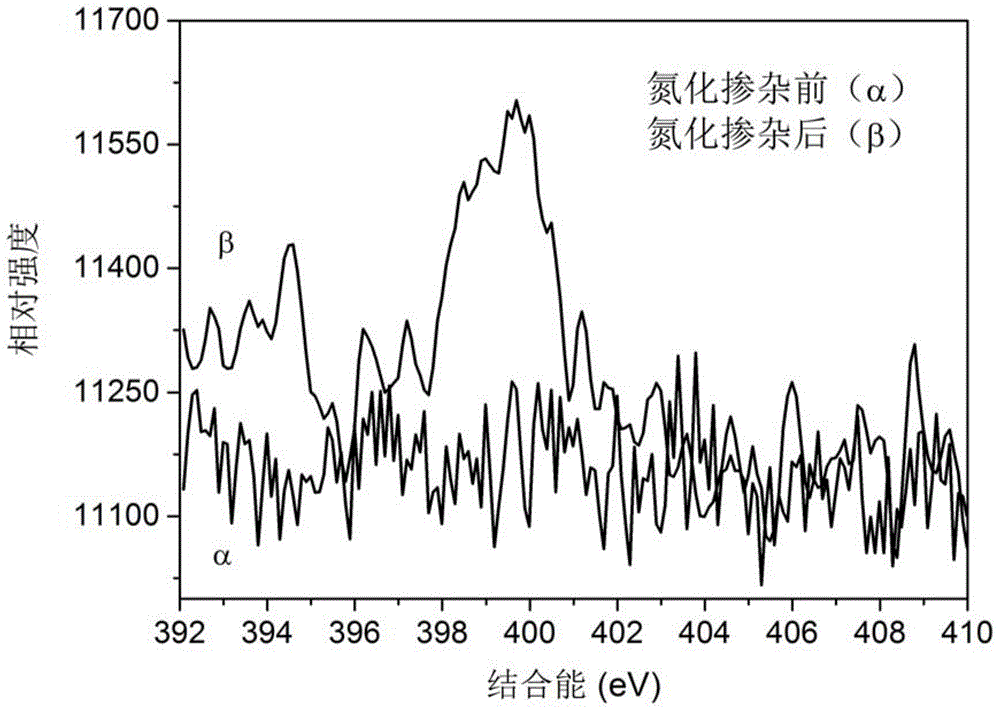

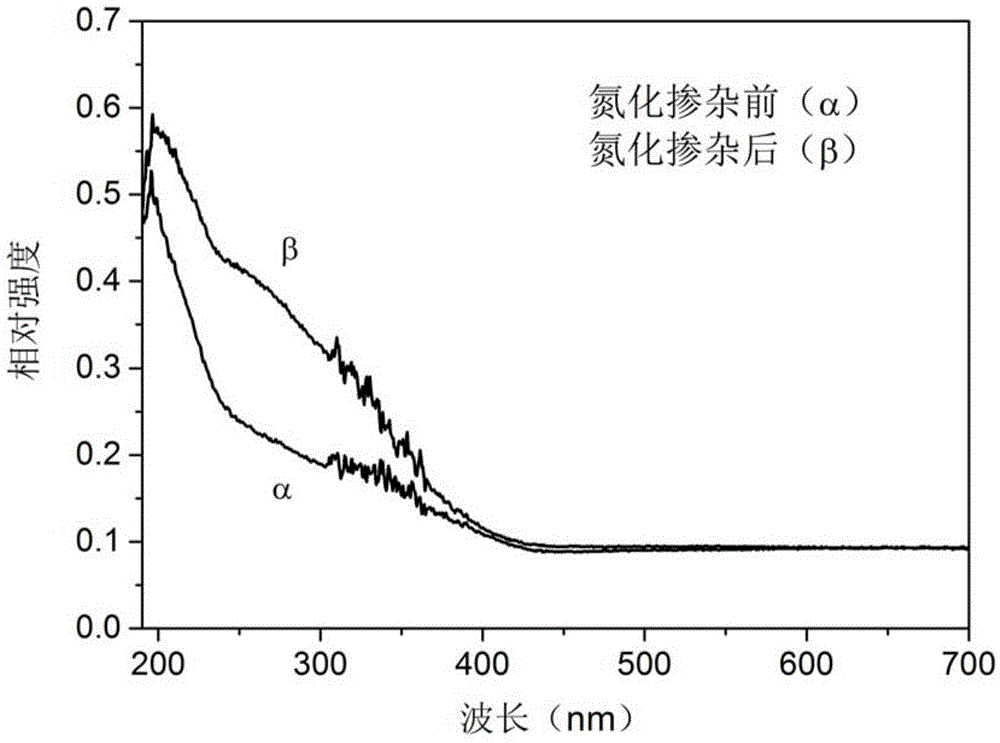

[0058] Weigh BaCO according to the molar ratio of Ba:In:B is 3.0:1.0:9.0 (+0.02~0.06) 3 、In 2 o 3 and H 3 BO 3 ; pre-sintering after grinding; melting after cooling; then annealing, grinding after cooling to obtain Ba 3 InB 9 o 18 Powder; the Ba 3 InB 9 o 18 The powder and urea powder are placed adjacent to the center of the heating zone of the quartz tube of the tube furnace. After the quartz tube is evacuated, the quartz tube is filled with Ar gas; Ba 3 InB 9 o 18 powder. figure 1 It is the nitride-doped Ba prepared in Example 1 3 InB 9 o 18 and Ba 3 InB 9 o 18 The X-ray diffraction patterns of the two have the same diffraction peaks, indicating that the crystal structure has not changed after nitriding doping. figure 2 Is the nitrogen-doped Ba prepared in Example 1 of the present invention 3 InB 9 o 18 and Ba 3 InB 9 o 18 The X-ray photoelectron energy spectrogram,...

Embodiment 2

[0069] In the preparation conditions of Example 1, the placed urea powder was changed to placed biuret powder, and the other synthesis conditions were unchanged to prepare the nitriding doped Ba with biuret as the nitrogen source. 3 InB 9 o 18 . Figure 10 For the X-ray diffraction pattern of the synthetic sample of this embodiment, Figure 11 It is the X-ray photoelectron spectrum of the sample synthesized in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com