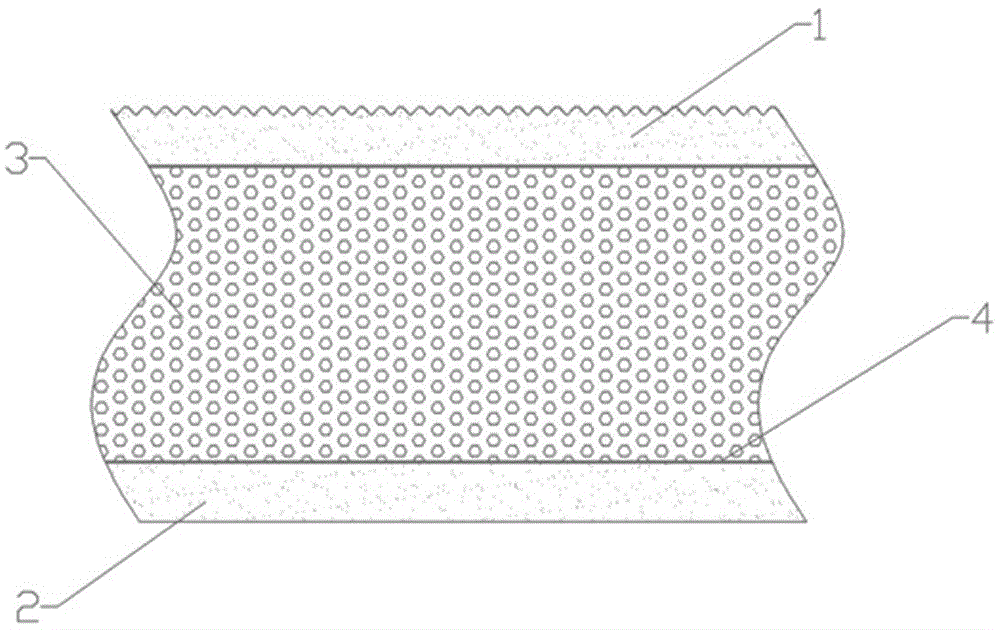

A shockproof, sound-insulating and heat-insulating lightweight partition wall board and its manufacturing method

A production method and a technology for sound insulation and heat preservation, applied in the field of building materials, can solve the problems of complex production process, cracking and shelling, and easy shelling of the joint surface, and achieve the effect of good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A kind of production steps of shockproof sound insulation insulation partition wall board:

[0022] A. Lay fiber mesh on the mould;

[0023] B. Pouring the first reinforcing surface layer, feeding the material to the mold, the feeding material is in the form of porridge, and the feeding material is a mixture containing cement, fly ash and iron slag, and it is rolled by a roller while feeding, in step A The fiber mesh is located inside the first reinforcement surface layer; the weight ratio of cement, fly ash and iron slag is 10:2.5:1, and the steel mesh and fiber mesh are pressed into the material by rolling to ensure the first reinforcement The thickness of the surface layer is 8 mm;

[0024] C, laying fiber net;

[0025] D. Pour the sound insulation layer on the first reinforced surface layer, and feed the material to the mold. The material is in the form of porridge, and the material is a mixture containing cement, fly ash and polystyrene particles. Vibration, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com