Method and device for measuring non-soluble iron content of thermodynamic system of thermal power plant unit

A technology for insoluble iron and thermal power plants, applied in the direction of removing certain components and weighing, etc., can solve the problems of high price, long overhaul period, and inability to achieve continuous monitoring of iron, and achieve continuous monitoring and equipment costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

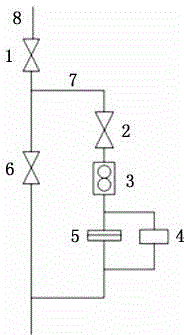

Image

Examples

Embodiment 1

[0028] For a 600MW unit, the water supply adopts AVT(R) treatment method. During the unit overhaul inspection, it was found that the deposition rate of the water wall, economizer, and steam turbine blades was relatively high, and the scaling rate of the water wall toward the fire side was 95 g / (m 2 a), the fouling rate of the economizer to the smoke side is 73 g / (m 2 ·a), the maximum rate of salt accumulation on the blades of the high-pressure cylinder of the steam turbine is 5.4mg / (cm 2 • a). In order to reduce the deposition rate and improve the safety and economy of unit operation, after the unit is chemically cleaned, the feed water of the unit is subjected to oxidation treatment. After two years of oxidation treatment, the unit is overhauled and inspected. The scale rate is 34 g / (m 2 ·a), the fouling rate of the economizer to the smoke side is 29 g / (m 2 ·a), the maximum rate of salt accumulation on the blades of the high-pressure cylinder of the steam turbine is 1.4mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com