Optical power measuring device

A measurement device and optical power technology, applied in transmission monitoring/testing/fault measurement systems, etc., to achieve the effect of easy use and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

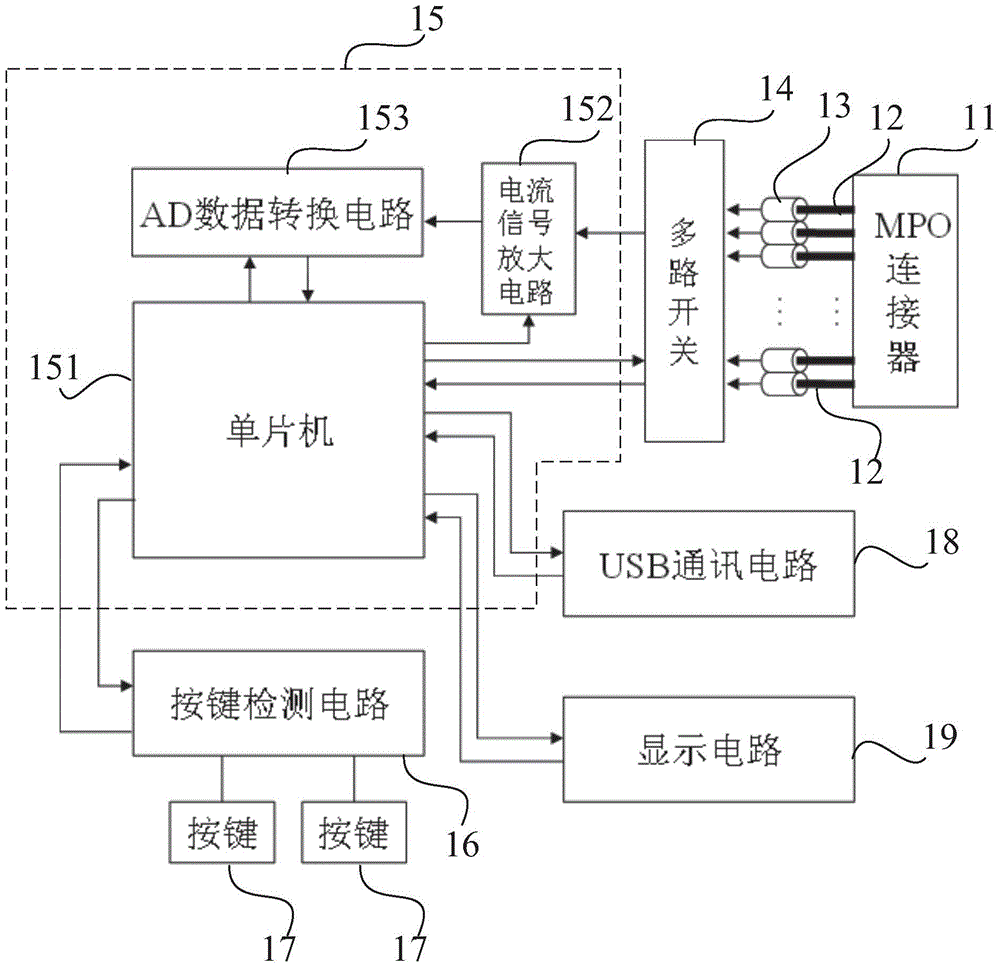

[0032] A kind of optical power measuring device, is used for measuring the power of the multi-path laser signal that transmits in a tested ribbon fiber, see figure 1 , the optical power measurement device includes:

[0033] An MPO connector 11 is used to realize the detachable (movable) connection between the optical fiber and the optical fiber. It precisely butts the two end faces of the optical fiber so that the optical energy output by the transmitting optical fiber can be coupled into the receiving optical fiber to the maximum extent. Go, and minimize the impact on the system due to its intervention in the optical link;

[0034] A ribbon optical fiber 12 with the same number of cores as the number of channels of the MPO connector 11;

[0035] The number of first detectors 13 is the same as the number of channels of the MPO connector 11, the first detector can be an indium gallium arsenide photodetector (InGaAs), the effective detection diameter is 75 μm (micrometer), and ...

Embodiment 2

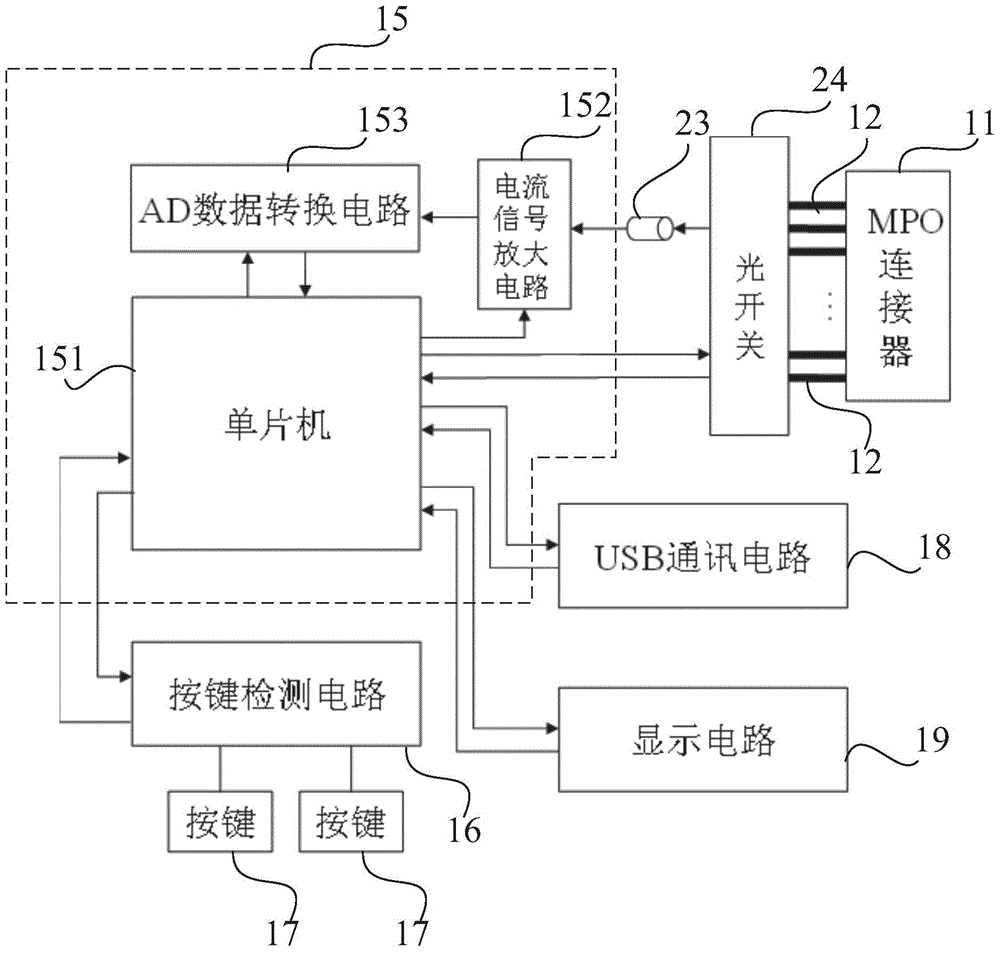

[0045] This embodiment is basically the same as Embodiment 1, the difference is that, see figure 2 , the optical power measuring device of the present embodiment does not include the first detector 13 and the multi-way switch 14 whose number is the same as the number of channels of the MPO connector 11, but includes:

[0046] A second detector 23 and an optical switch 24 (such as a MEMS optical switch) for converting laser signals into current signals; the ribbon fiber 12 is synchronously connected to each channel of the MPO connector 11 and the optical switch 24 for each of the inputs. The output end of the optical switch 24 is electrically connected to the current signal amplifying circuit 152 through the second detector 23 , and the single-chip microcomputer 151 is used to control the optical switch 24 to output a laser signal.

[0047] When using the optical power measuring device to measure the multiple laser signals transmitted in the tested ribbon fiber, it is necessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com