Hollow electrode medium blocking structure

A dielectric barrier, hollow electrode technology, applied in electrical components, plasma and other directions, can solve the problem of increased difficulty in exciting air, and achieve the effects of easy portability, low cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

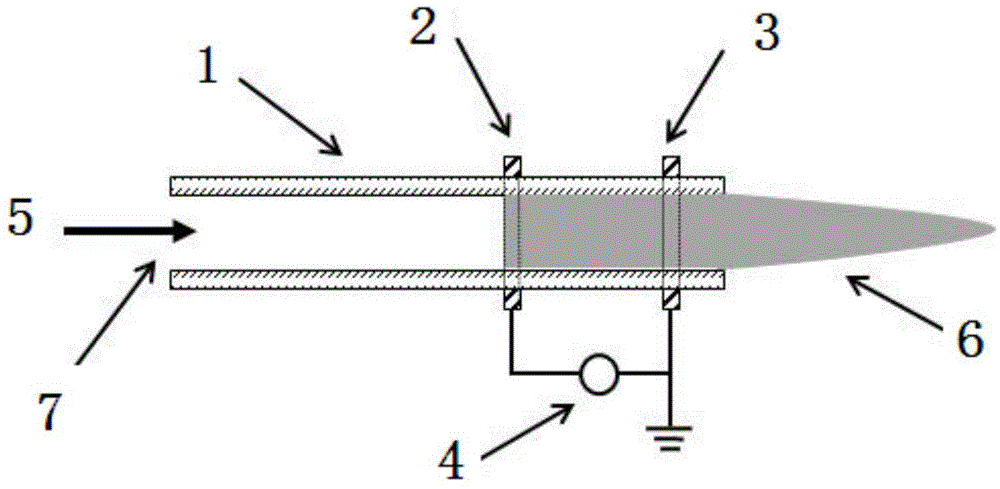

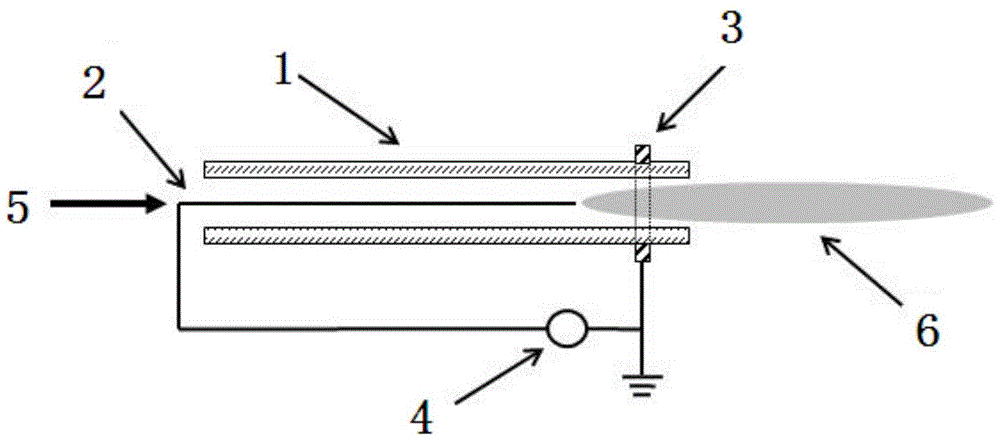

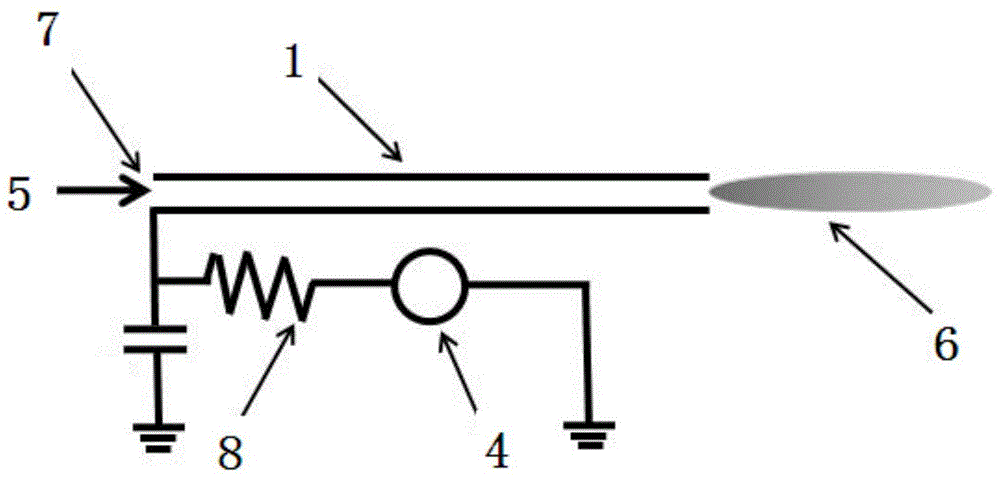

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The section length of the air outlet 17 is adjusted to be 1 / 3, 2 / 3 and 1 time of the air inlet 15 respectively, the working gas 18 is air, and the air flows in at a flow rate of 300 L / h through the adjustment of the gas control switch 16 Hollow discharge structure, the frequency 20kHz power supply 13 constantly raises the voltage to excite the hollow discharge structure.

[0037] Such as Figure 6 As shown, the result of the electron density of Example 1 of the present invention increases with the reduction of the gas outlet 17, and the electron density is as high as 10 15 / cm 3 Magnitude.

[0038] Such as Figure 7 As shown, the gas pressure and turbulence distribution results in Embodiment 1 of the present invention decrease with the reduction of the gas outlet 17 (as Figure 7 (a)~ Figure 7 As shown in (c), the internal pressure of the hollow electrode dielectric barrier structure increases, and there is obvious turbulence.

Embodiment 2

[0039] Embodiment 2: The working gas 18 is air, and the air flow rate is controlled by the gas control switch 16 to flow into the hollow discharge structure at 200L / h, 300L / h and 400L / h respectively, and the cross-sectional length of the air outlet 17 is 1 of the air inlet 15. / 3, the high voltage power supply 13 with a frequency of 20kHz continuously raises the voltage to excite the hollow discharge structure.

[0040] Such as Figure 8 As shown, the result of the electron density in Example 2 of the present invention increases with the increase of the air flow velocity, and the electron density is continuously increased, and the electron density is as high as 10 15 / cm 3 Magnitude.

[0041] Such as Figure 9 As shown, the gas pressure and turbulence distribution results increase with the increase of the air flow velocity in the second embodiment of the present invention (as Figure 9 (a)~ Figure 9 As shown in (c), the internal pressure of the hollow electrode dielectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com