Apparatus and methods for processing substrates

A technology for substrates and equipment, applied in the field of processing coated substrates, can solve problems such as unsealing, consumption, interruption, etc., and achieve the effects of low input cost and maintenance cost, small wear, and avoidance of loading corrosive substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

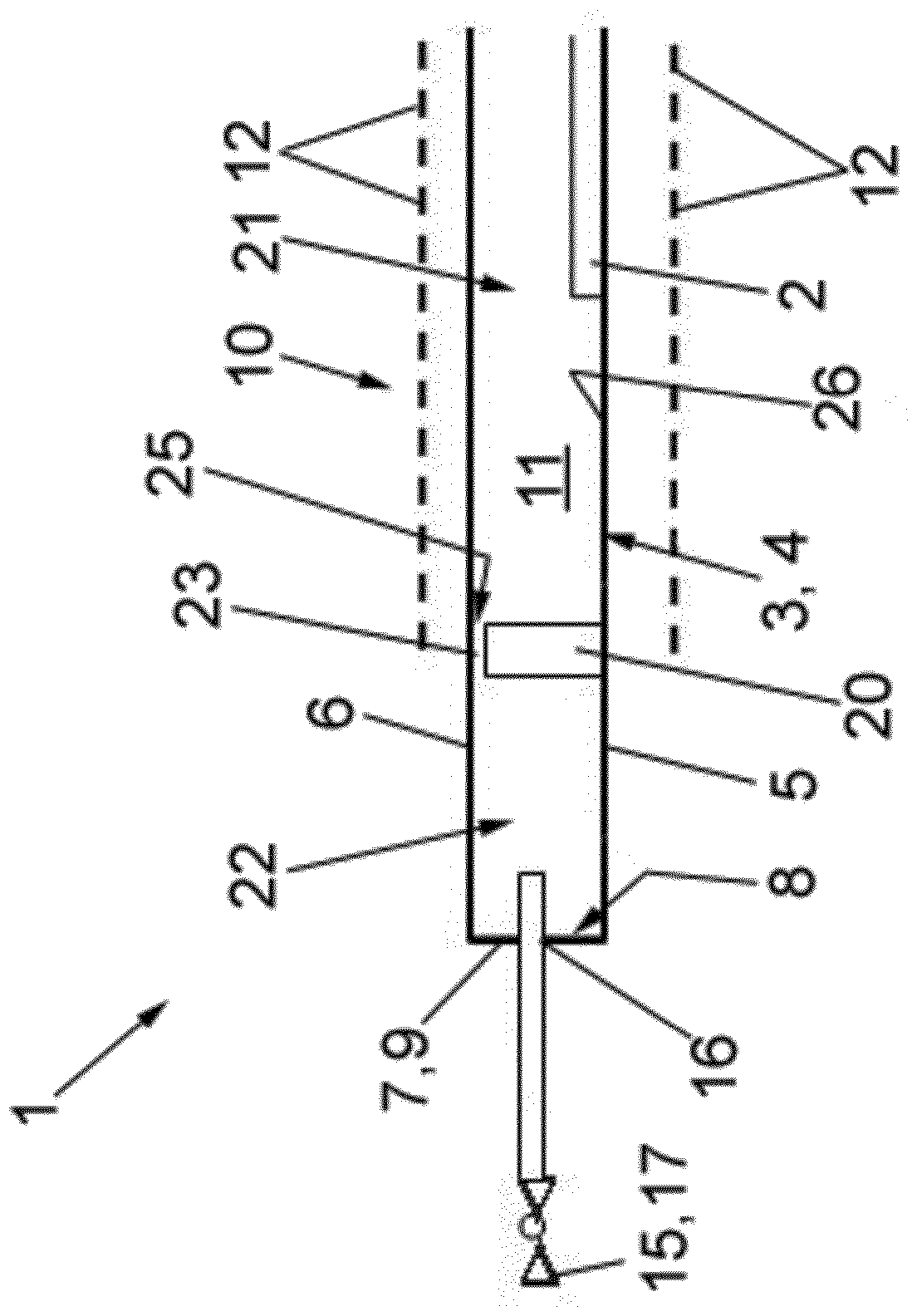

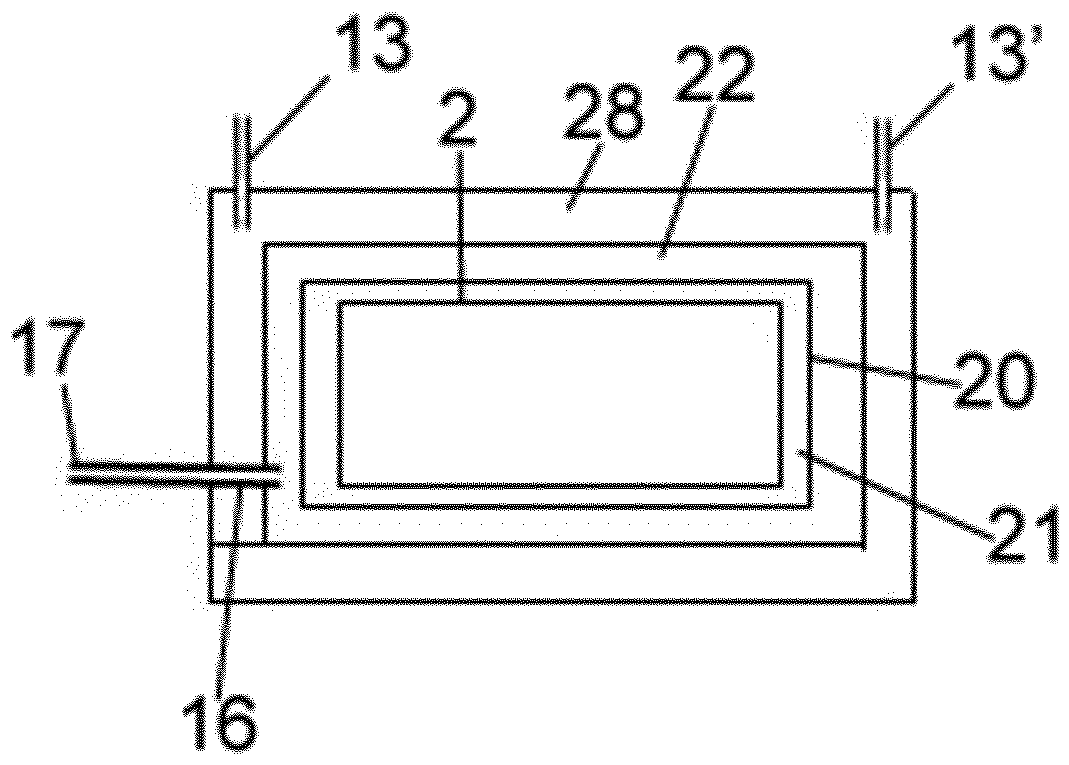

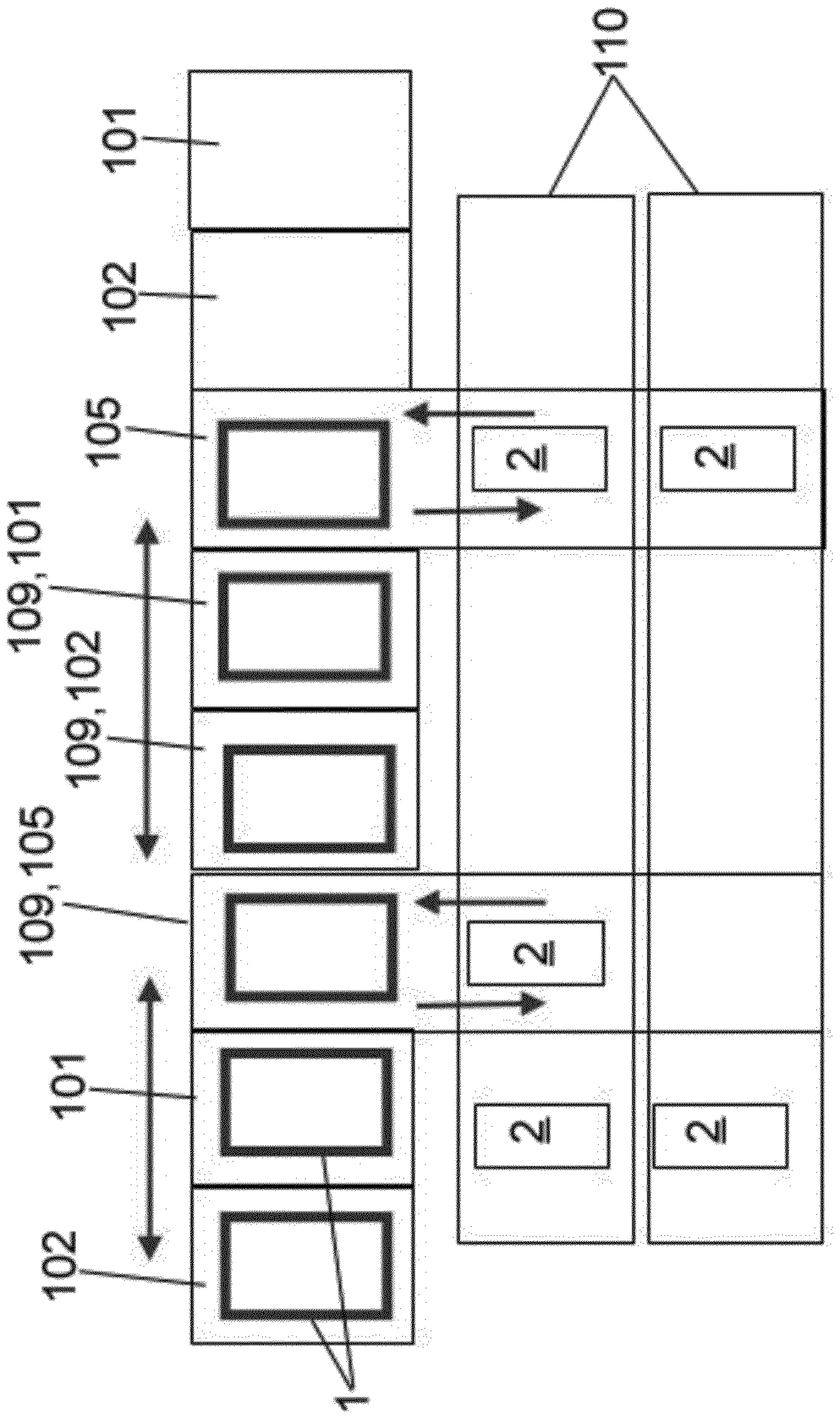

[0110] exist Figures 1 to 5A A process box oriented horizontally in a typical working position is illustrated in -5F. It is understood that the treatment tank can also be oriented differently and that the positions and orientations stated in the following description refer only to the illustration of the treatment tank in the figures, and this is not to be understood as limiting.

[0111] first observe figure 1 and 2 , which shows a generalized cross-sectional view of a processing box 1 for processing a coated substrate 2 ( figure 1 ) and a perspective view of such a treatment box 1 with an end-side closure part 9 ( figure 2 ).

[0112] The treatment box 1 is used for the treatment of substrates 2 coated on one side, for example for the thermal treatment of precursor layers for conversion into compound semiconductors, in particular chalcopyrite compounds. Although only a single substrate 2 is shown, the processing box 1 can equally be used for processing two or more sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com