Three-level separation type cyperus esculentus harvester

A technology of oily bean and harvester, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of high labor intensity, reduced harvest, multi-manpower and material resources, etc., to achieve high net rate, avoid waste, The effect of improving the net rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

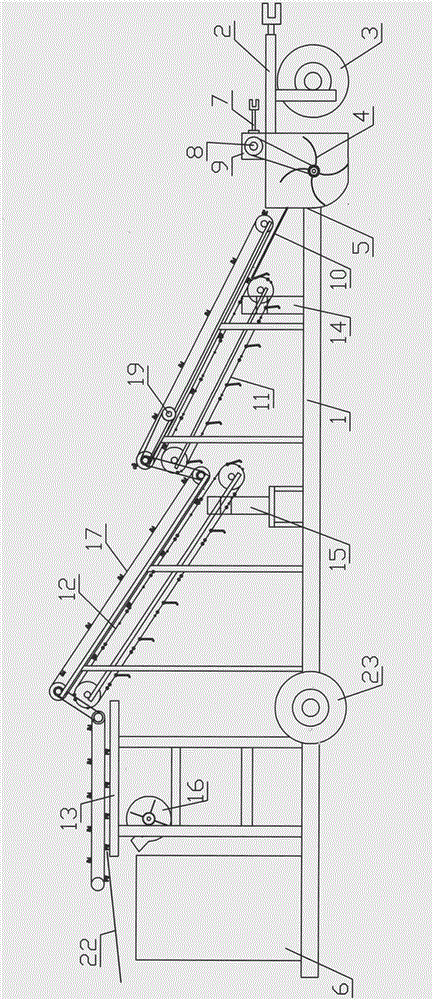

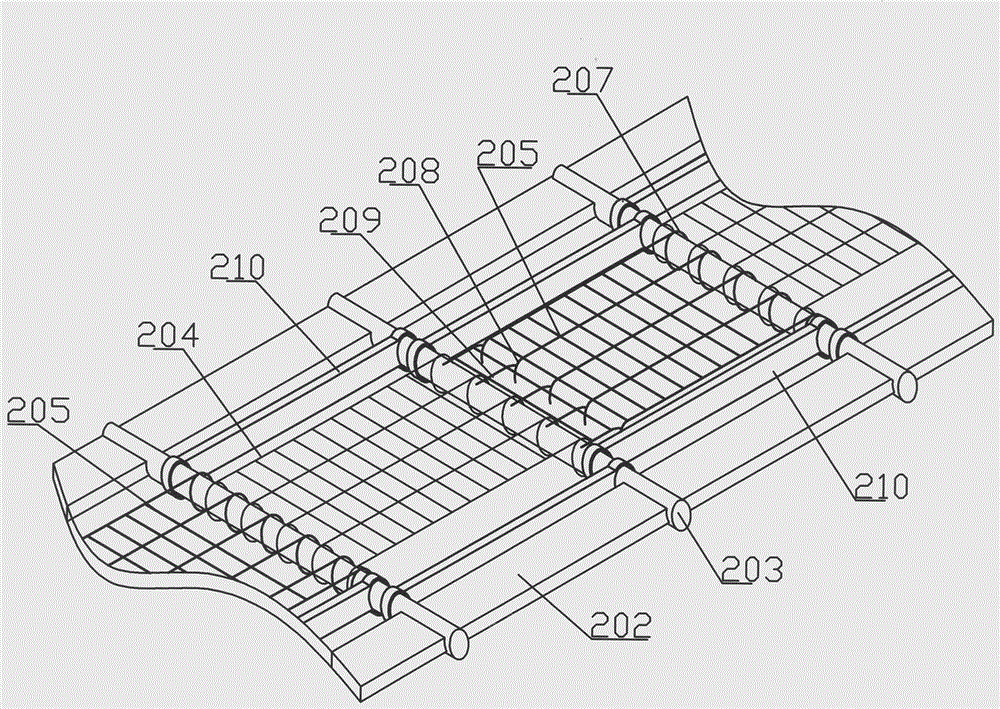

[0029] Embodiment 1: as Figure 1 to Figure 6As shown, the three-stage sorting oil sand bean harvester includes a frame main body 1, a traction frame 2, a depth-fixing wheel 3, a rotary harrow 4, a shovel plate 5, a material storage box 6, and a traveling wheel 23. The top of the front end of the frame main body 1 is provided with a drive shaft 7 whose axial direction is the same as the traveling direction of the frame main body 1, and a transmission shaft 8 whose axial direction is perpendicular to the traveling direction of the frame main body 1; the driving shaft 7 and the transmission shaft 8 are transmitted through a transmission gearbox 9 connection; one end of the transmission shaft 8 is connected to the rotary harrow 4 through a chain transmission; the frame main body 1 behind the shovel plate 5 is provided with a transition plate 10 connected end to end and arranged front and back, a primary screening device 11, and a secondary screening device 12 and a third-stage sc...

Embodiment 2

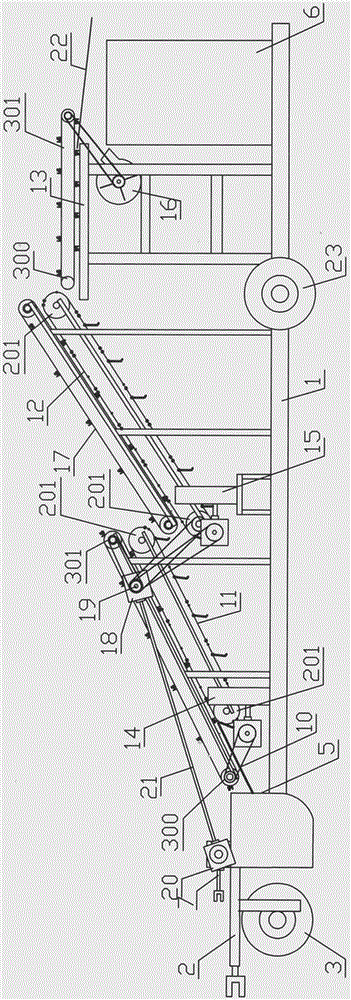

[0031] Embodiment 2: as Figure 4 to Figure 9 As shown, the three-stage sorting oil sand bean harvester includes a frame main body 1, a traction frame 2, a depth-fixing wheel 3, a rotary harrow 4, a shovel plate 5, a material storage box 6, and a traveling wheel 23. The top of the front end of the frame main body 1 is provided with a drive shaft 7 whose axial direction is the same as the traveling direction of the frame main body 1, and a transmission shaft 8 whose axial direction is perpendicular to the traveling direction of the frame main body 1; the driving shaft 7 and the transmission shaft 8 are transmitted through a transmission gearbox 9 connection; one end of the transmission shaft 8 is connected to the rotary harrow 4 through a chain transmission; the frame main body 1 behind the shovel plate 5 is provided with a transition plate 10 connected end to end and arranged front and back, a primary screening device 11, and a secondary screening device 12 and the third-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com