Method and testing device for reducing membrane pollution through alternate inhomogeneous field

A non-uniform electric field and experimental device technology, applied in chemical instruments and methods, electrodialysis, membrane technology, etc., can solve the problems of imperfection, unadjustable high-voltage pulse size and frequency, inconvenient use, etc. The effect of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

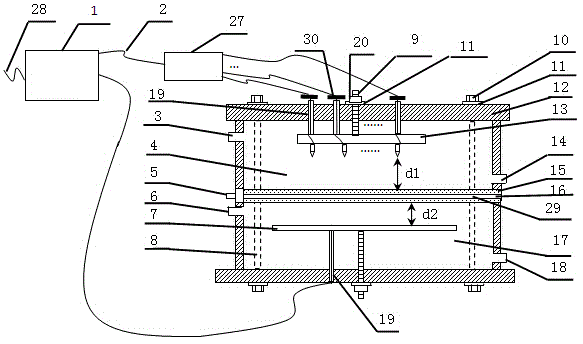

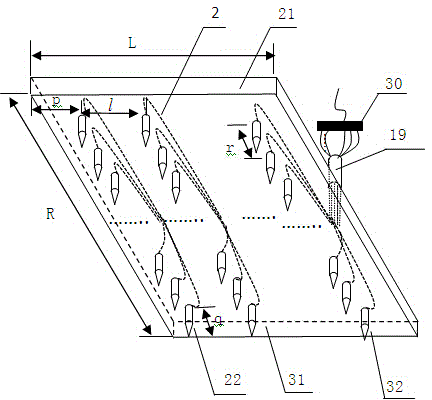

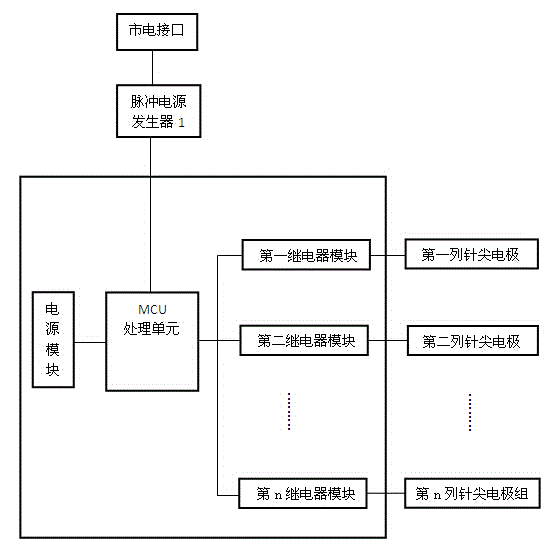

[0021] See figure 1 The main part of the alternate non-uniform electric field mitigation membrane fouling device of the present invention is a vertical symmetric structure with the flat microfiltration membrane 29 as the center of symmetry. The external protection device 12 is located outside the main body of the entire device for protection and fixation. The flat microfiltration membrane 29 is horizontally located in the middle part of the entire device, and the device is equally divided into two parts in volume. The flat microfiltration membrane 29 is composed of a membrane layer and a membrane pad 15, a filter plate 16, and a water intake 5. The filter plate 16 supports the membrane layer and membrane pad 15 attached to its upper and lower surfaces. There are many grooves on the filter plate 16. The trough can lead the material liquid filtered through the membrane layer and the membrane pad 15 to the water intake 5 and flow out from the water intake 5 under the action of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com