Method for generating emulsion in micro-channel

A microchannel and microfluidic channel technology, which is used in the field of emulsion generation in microchannels, can solve the problems of inability to realize the size and volume of the emulsion, as well as the dispersion and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

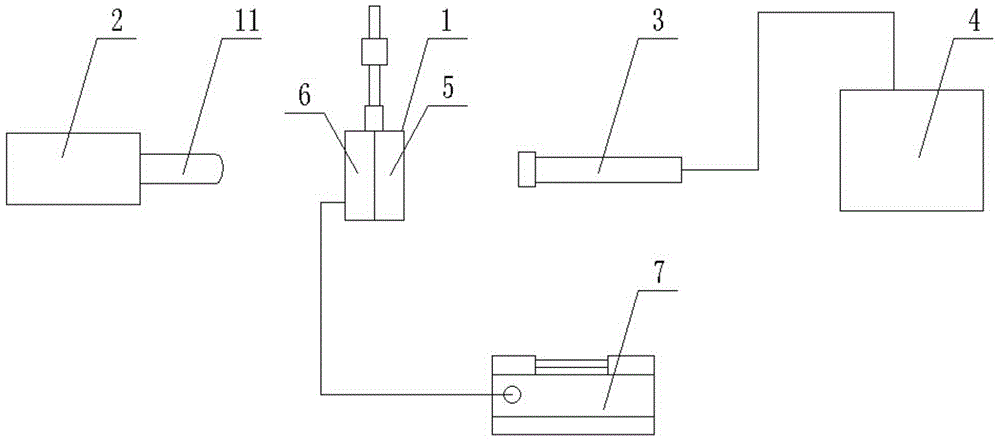

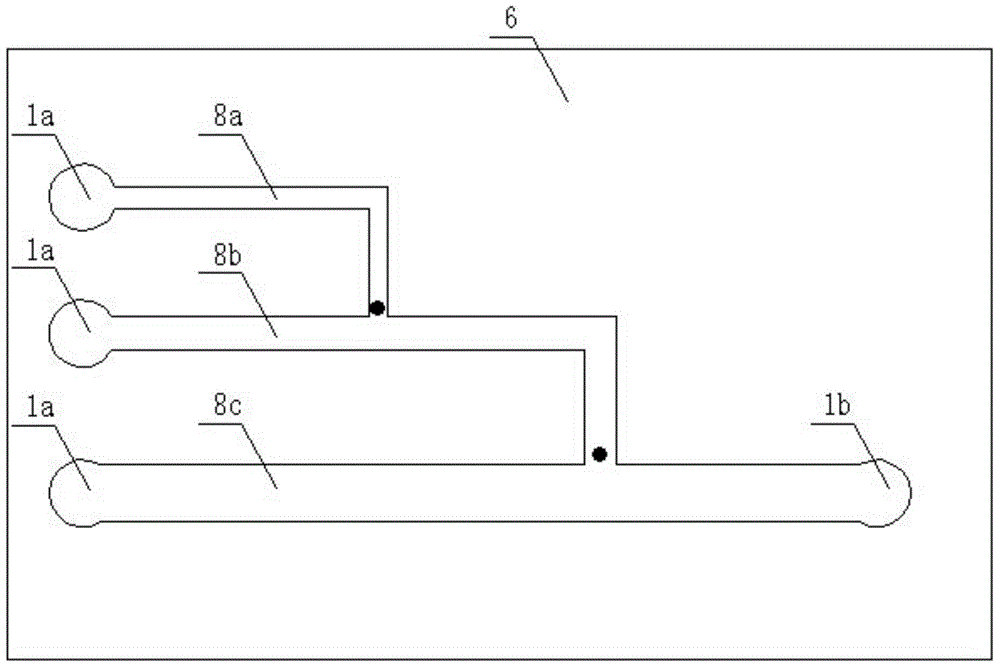

[0022] like figure 1 , figure 2 As shown, this embodiment includes the following steps:

[0023] a. Make a microfluidic channel mold on the silicon wafer, pour the prepared polydimethylsiloxane solution on the silicon wafer, and then put it on the heating plate to bake. A piece of polydimethylsiloxane 5 is torn off from the silicon chip, then forms microchannel on the surface of the first piece of polydimethylsiloxane 5, and this microchannel comprises primary emulsification inlet channel 8a, secondary emulsion The inlet channel 8b and the emulsion forming channel 8c, the inlet end of the primary emulsification inlet channel 8a, the inlet end of the secondary emulsion inlet channel 8b and the inlet end of the emulsion forming channel 8c are all provided with an inlet hole 1a and a microfluidic chip 1 External communication, the outlet end of the primary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com