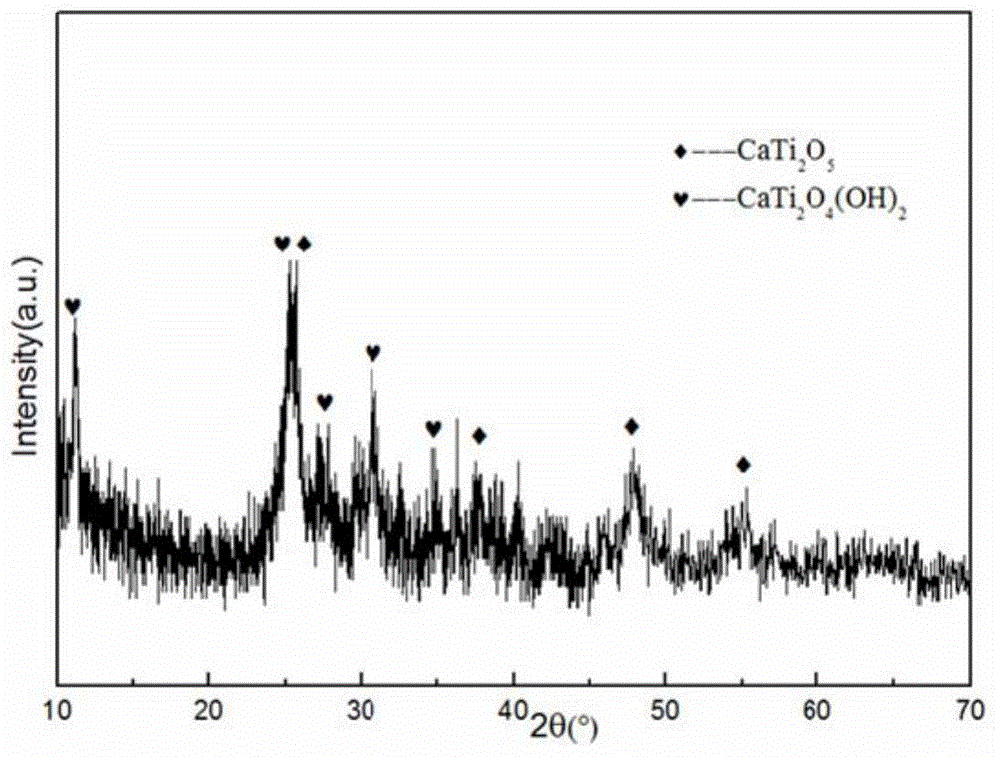

CaTi2O5/CaTi2O4(OH)2 composite micro-nano structure material and preparation method thereof

A micro-nano structure and sheet-like structure technology, applied in the field of photocatalysis, can solve the problems of complex conditions of metastable micro-nano structure materials, no composite micro-nano structure materials, unfavorable industrial production, etc., and achieve excellent photocatalytic performance , Improve the use value and economic benefits, and promote the effect of application and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example CaTi 2 O 5 / CaTi 2 O 4 (OH) 2 The preparation method of composite micro-nano structure material, its steps are as follows:

[0023] (1) Dissolve butyl titanate in ethanol, according to the molar ratio of butyl titanate: ethanol = 1:5, stir until uniform to obtain liquid A;

[0024] (2) Dissolve anhydrous calcium chloride in distilled water, then mix with ethanol, and stir until uniform to obtain liquid B; according to the molar ratio of anhydrous calcium chloride: distilled water: ethanol = 1:50:10;

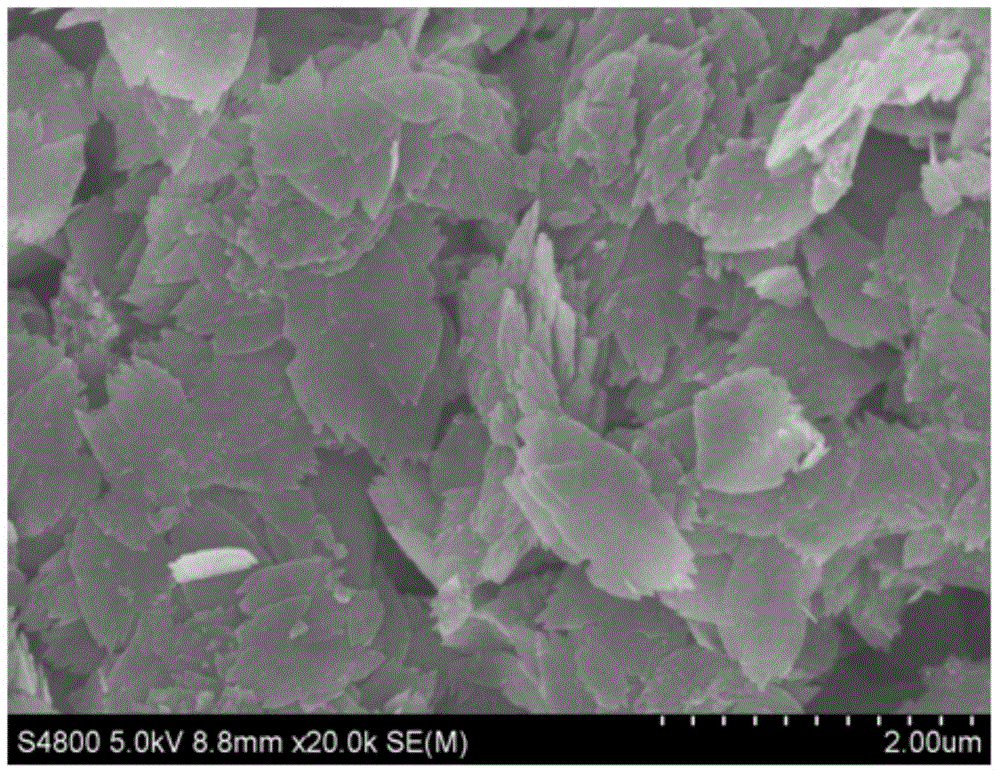

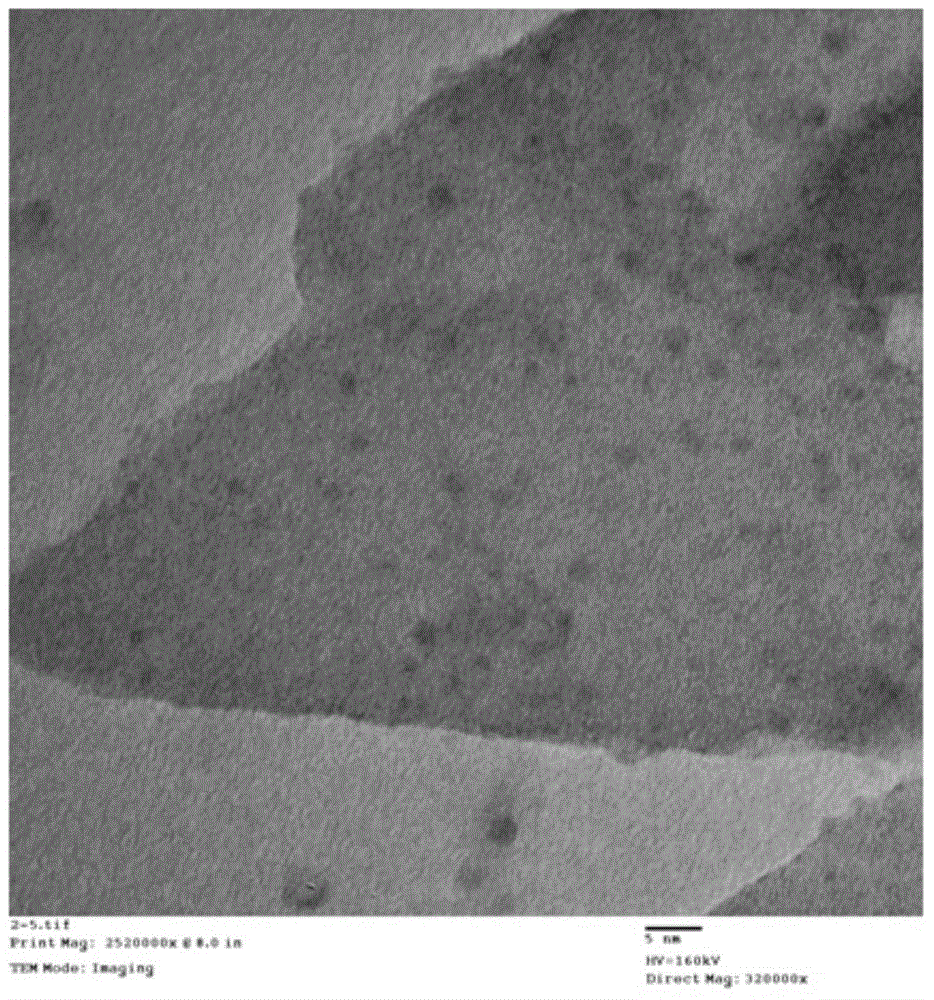

[0025] (3) According to the molar ratio of butyl titanate:anhydrous calcium chloride = 1:1, drop the above A solution into the B solution and stir for 10 minutes, then add 3M / L NaOH solution dropwise and continue stirring for 15 minutes, according to the molar ratio Ratio NaOH solution: distilled water = 0.02:1; then put it in a hydrothermal kettle, keep it at 180℃ for 36h, wash with distilled water 6 times to obtain CaTi 2 O 4 (OH) 2 Flake structure supports CaTi 2 O 5 N...

Embodiment 2

[0027] Example CaTi 2 O 5 / CaTi 2 O 4 (OH) 2 The preparation method of composite micro-nano structure material, its steps are as follows:

[0028] (1) Dissolve butyl titanate in ethanol, according to the molar ratio of butyl titanate:ethanol=1:10, stir until uniform to obtain liquid A;

[0029] (2) Dissolve anhydrous calcium chloride in distilled water, then mix it with ethanol, and stir until uniform to obtain liquid B; according to the molar ratio of anhydrous calcium chloride: distilled water: ethanol = 1:400:5;

[0030] (3) According to the molar ratio of butyl titanate:anhydrous calcium chloride = 1:1, drop the above A solution into the B solution and stir for 10 minutes, then add 3M / L NaOH solution dropwise and continue stirring for 15 minutes, according to the molar ratio Ratio NaOH solution: distilled water=0.06:1; then put it in a hydrothermal kettle, keep it at 160℃ for 36h, wash with distilled water 6 times to obtain CaTi 2 O 4 (OH) 2 Flake structure supports CaTi 2 O 5 Na...

Embodiment 3

[0032] Example CaTi 2 O 5 / CaTi 2 O 4 (OH) 2 The preparation method of composite micro-nano structure material, its steps are as follows:

[0033] (1) Dissolve butyl titanate in ethanol, according to the molar ratio of butyl titanate: ethanol = 1:8, stir until uniform to obtain liquid A;

[0034] (2) Dissolve anhydrous calcium chloride in distilled water, then mix with ethanol, and stir until uniform to obtain liquid B; according to the molar ratio of anhydrous calcium chloride: distilled water: ethanol = 1:200:10;

[0035] (3) According to the molar ratio of butyl titanate:anhydrous calcium chloride = 1:1, drop the above A solution into the B solution and stir for 10 minutes, and then add the 3M / L KOH solution dropwise and continue to stir for 5 minutes. Ratio KOH solution: distilled water=0.09:1; then put it in a hydrothermal kettle, keep it at 220℃ for 12h, wash with distilled water 6 times to obtain CaTi 2 O 4 (OH) 2 Flake structure supports CaTi 2 O 5 Nanoparticles of CaTi 2 O 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com