A single-layer hexagonal ag 3 po 4 /fe 3 o 4 /co‑ni LDH Composite Preparation Method

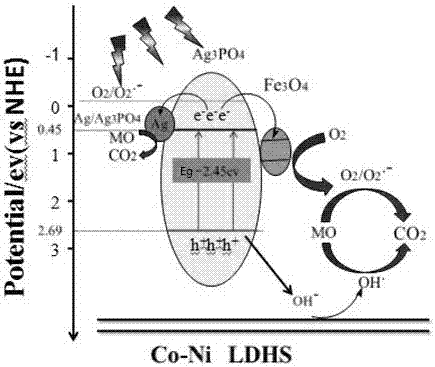

A composite material, single-layer technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve problems such as photocatalytic activity limitation and low utilization of sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

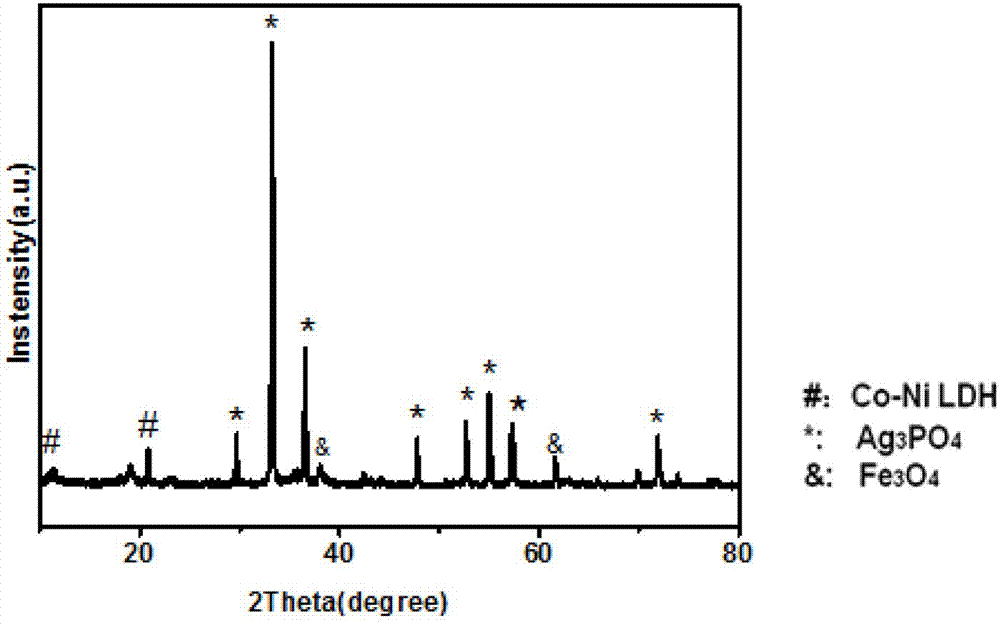

[0029] The monolayer hexagonal Ag of the present invention 3 PO 4 / Fe 3 o 4 / Co-Ni LDH composites were prepared as follows:

[0030] 1. Preparation of Co-Ni LDH

[0031] (1) 0.1189g CoCl 2 ·6H 2O, 0.059gNiCl 2 ·6H 2 O and 0.6308g hexamethylenetetramine are added to the distilled water of 100ml;

[0032] (2) Ultrasonic disperse the mixture for 10 minutes to fully dissolve it; there is no requirement for the frequency, as long as it is dispersed.

[0033] (3) Transfer the mixed solution into a 100ml reaction kettle and react at 120°C for 5h; the OH content contained in Co-Ni LDH prepared at 120°C is higher than that of Co-Ni LDH prepared at 95°C - More, it is beneficial to generate OH·;

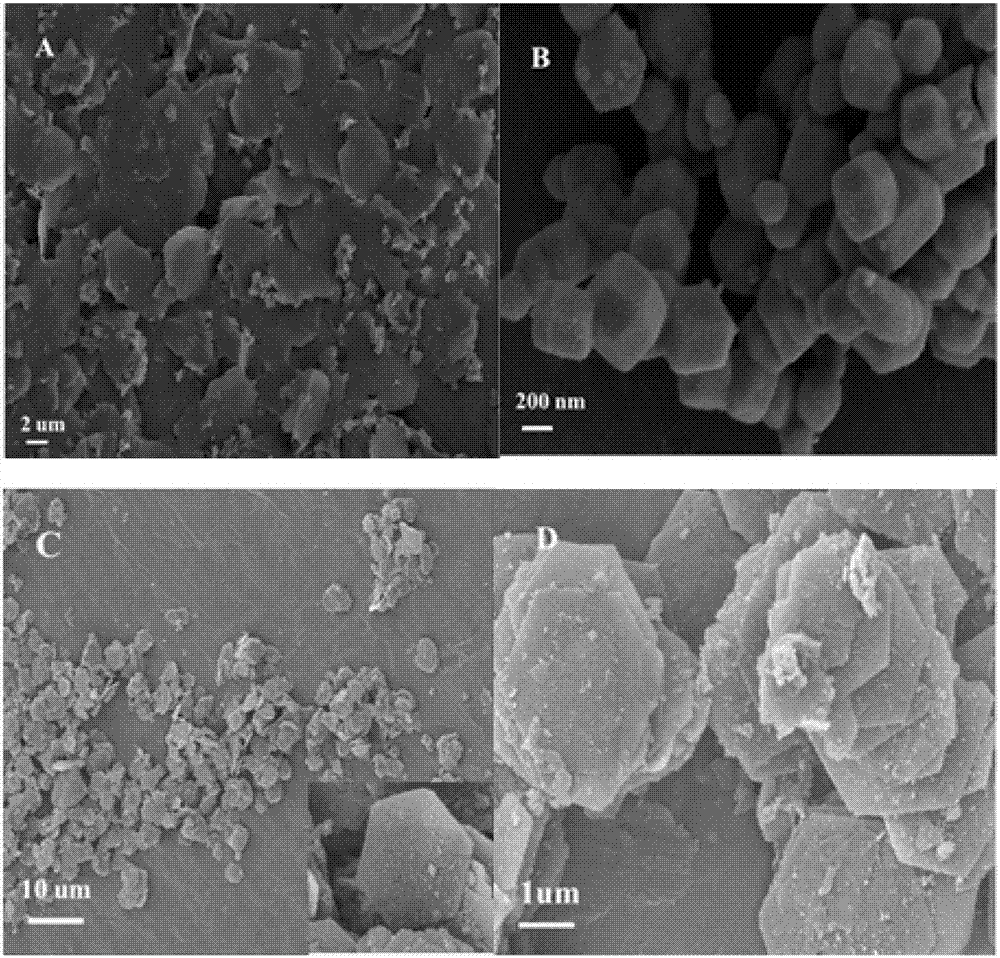

[0034] (4) After cooling, the mixture was suction-filtered, washed with secondary water until neutral, and a pale yellow precipitate was obtained, which was dried at room temperature to prepare Co-Ni LDH. figure 1 A is the scanning electron microscope image of the prepared Co-Ni LDH....

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049] Step 3CH 3 In the preparation of COOAg, AgNO 3 The concentration of the solution is 1.0 mol / L.

[0050] In step 4, the hexagonal Ag 3 PO 4 / Fe 3 o 4 The preparation method of / Co-Ni LDH composite material is: take the 0.089g Fe prepared in the above steps 3 o 4 Nanoparticles (0.387mmol), 0.065g Co-Ni LDH (0.698mmol) and Na 2 HPO 4 Dissolve 0.80g (0.0056mol) in 100ml of deionized water, stir for 24 hours, and rinse off excess Na 2 HPO 4 , to obtain a black precipitate by suction filtration, and dissolve the black precipitate in a solution containing 2.804g CH 3 COOAg (0.0168mol) in 50ml of deionized water was stirred for 24h, and the black powder obtained by suction filtration was dried at room temperature to obtain Co-Ni loaded Ag 3 PO 4 and Fe 3 o 4 Hexagonal layers of nanoparticles, i.e. hexagonal Ag 3 PO 4 / Fe 3 o 4 / Co-Ni LDH composites.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is:

[0053] Step 3CH 3 In the preparation of COOAg, AgNO 3 The concentration of the solution is 2.5mol / L.

[0054] In step 4, the hexagonal Ag 3 PO 4 / Fe 3 o 4 The preparation method of / Co-Ni LDH composite material is: take the 0.0479g Fe prepared in the above steps 3 o 4 Nanoparticles (0.2067mmol), 0.050g Co-Ni LDH (0.5376mmol) and Na 2 HPO 4 1.130g (0.0079mol) was dissolved in 100ml of deionized water, stirred for 24h, and excess Na was washed away 2 HPO 4 , to obtain a black precipitate by suction filtration, and dissolve the black precipitate in a solution containing 3.985g CH 3 COOAg (0.0237mol) in 50ml deionized water was stirred for 24h, and the black powder obtained by suction filtration was dried at room temperature to obtain Co-Ni loaded Ag 3 PO 4 and Fe 3 o 4 Hexagonal layers of nanoparticles, i.e. hexagonal Ag 3 PO 4 / Fe 3 o 4 / Co-Ni LDH composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com