Double-sided gluing machine for chip material in photo album with glue transfer shaft

A technology of inner chip and gluing machine, which is applied to the device and coating of the surface coating liquid, can solve the problems of poor economic and social benefits, small size of the inner sheet of the album, and the inability to recycle, etc., to achieve Significant economic and social benefits, maintaining thickness and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

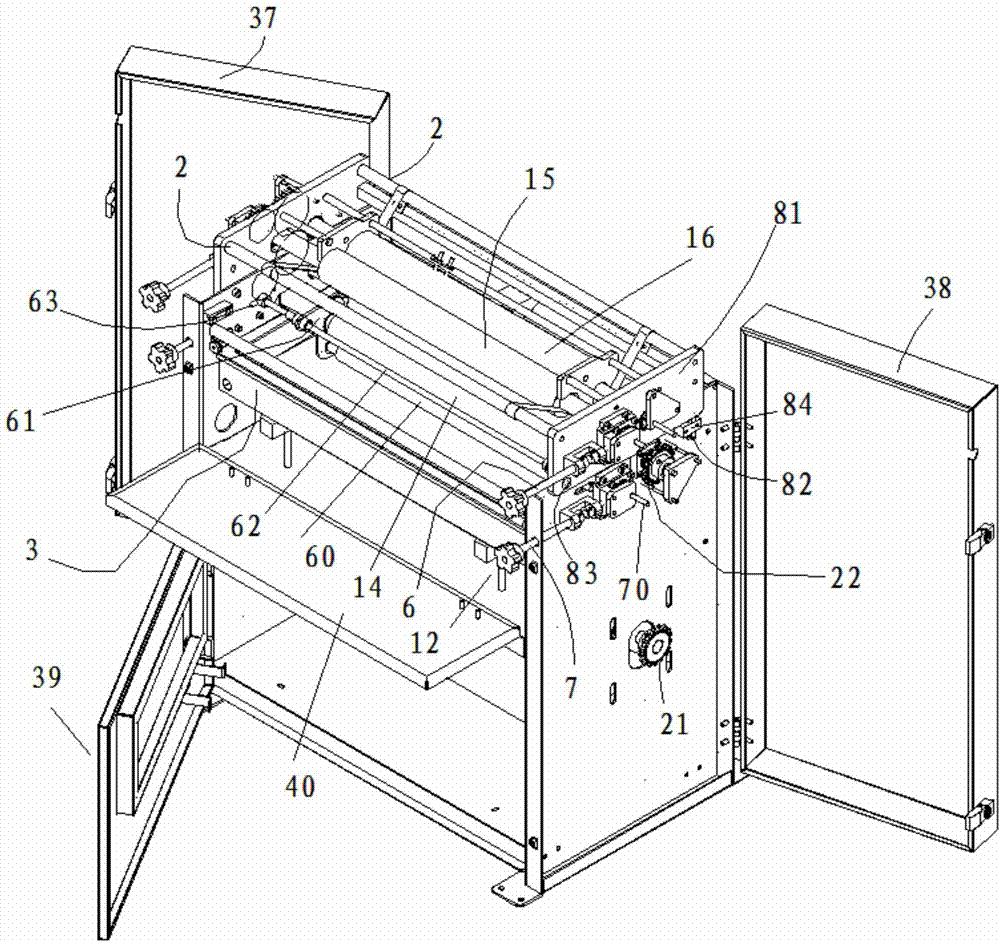

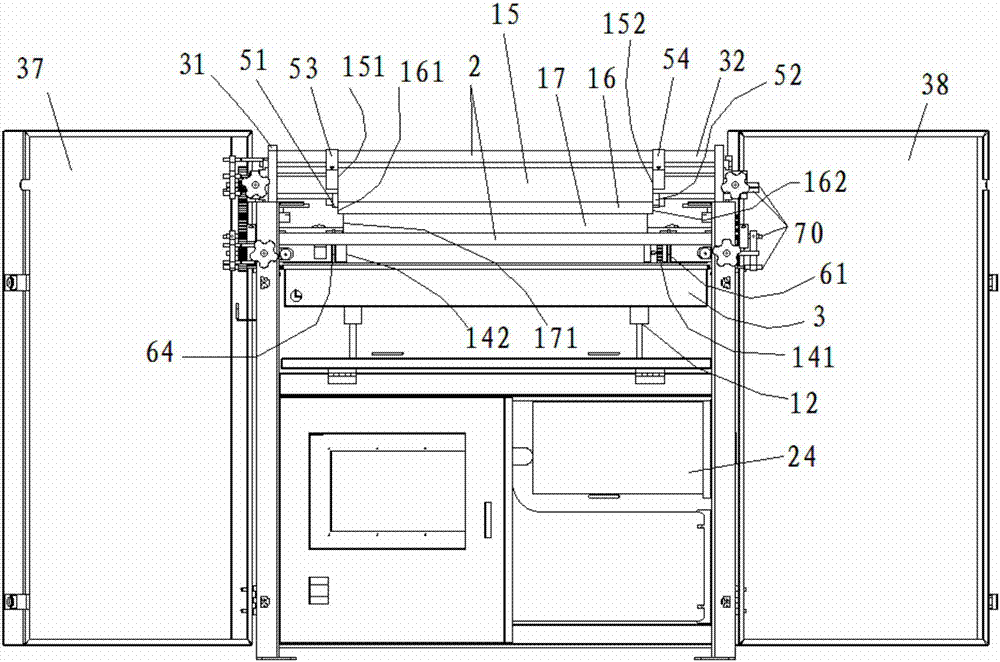

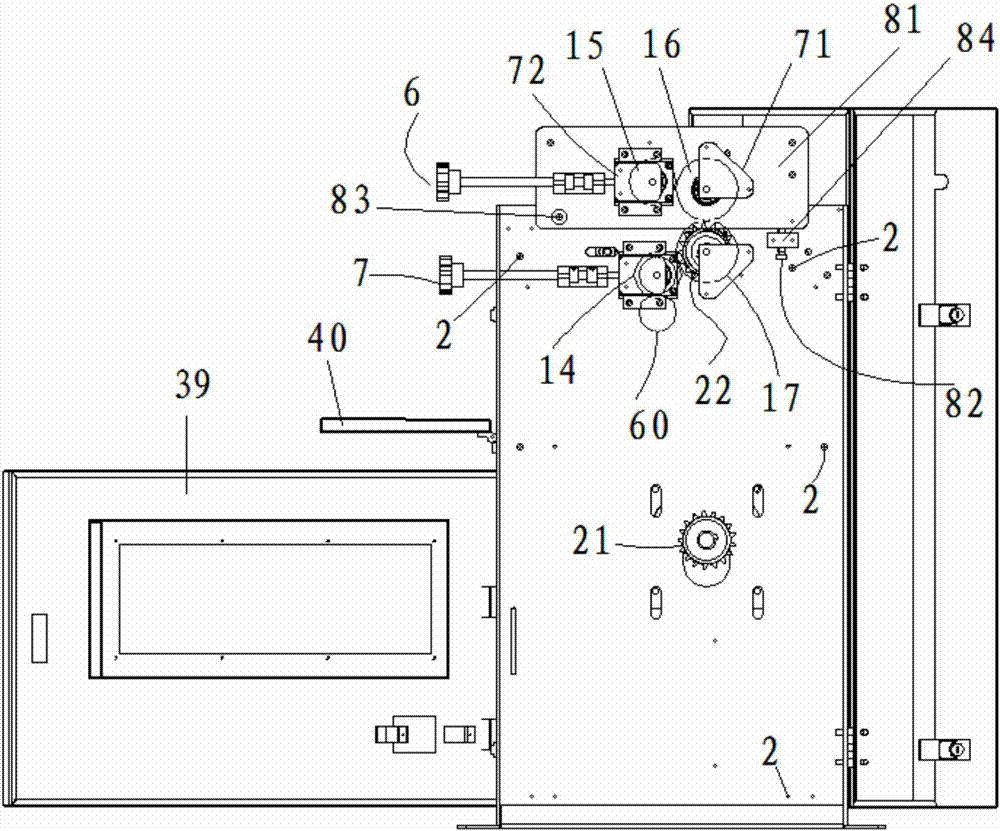

[0036] Such as Figure 1 to Figure 7 As shown, a double-sided gluing machine for album core material with a rubber transfer shaft includes a frame, an upper rubber shaft 16, a lower rubber shaft 17, an upper optical shaft 15, and a lower optical shaft 14. The frame includes left and right The vertical connecting plates on both sides, namely the left connecting plate 31 and the right connecting plate 32, the left connecting plate 31 and the right connecting plate 32 are connected by the horizontal connecting rod 2, and the horizontal connecting rod 2 is in the upper, middle and lower parts of the frame. The position is provided with multiple, the upper rubber shaft 16 and the lower rubber shaft 17 cooperate to drive the inner core material to move, and the two ends of the upper rubber sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com