Ferro-aluminum metal composite pot and machining method thereof

A technology of metal compounding and processing methods, which is applied to other household utensils, special materials for cooking utensils, cooking utensils, etc., to achieve the effects of simple processing methods, reducing energy consumption, and eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

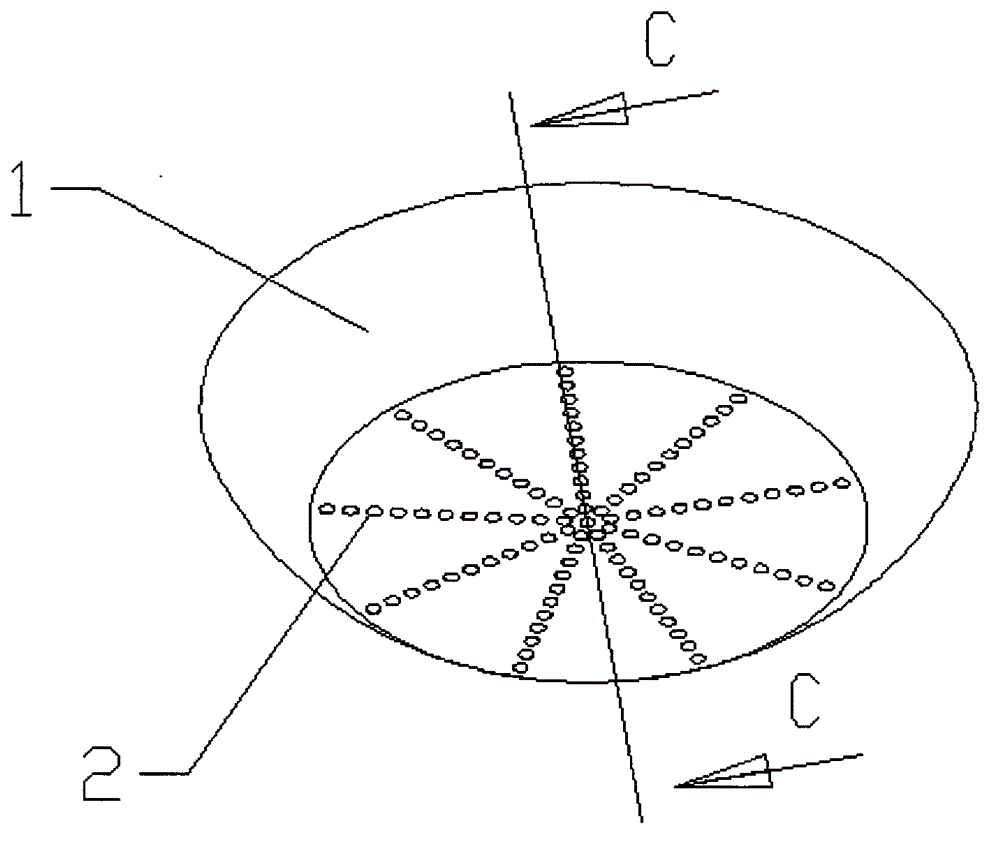

[0016] like figure 1 As shown, an aluminum-iron metal composite pot according to the present invention includes an iron pot body 1, and a circle of evenly distributed concave holes 2 is opened at the bottom of the pot body 1;

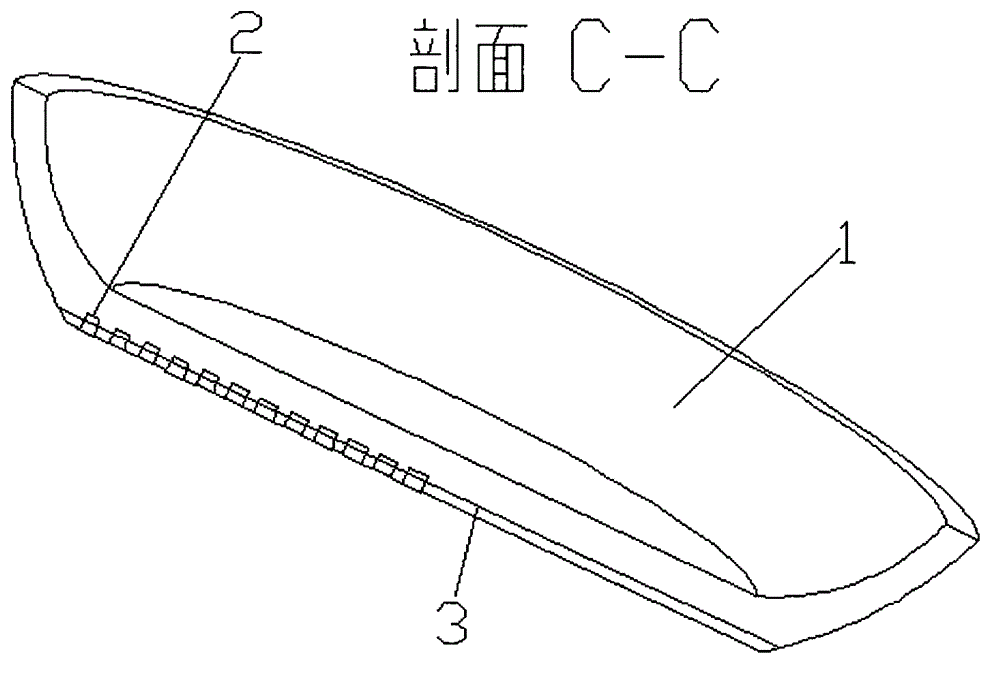

[0017] like figure 2 As shown, an aluminum plate 3 is pressed at the bottom of the above-mentioned pot body 1 by a mechanical pressing method, and part of the material of the above-mentioned aluminum plate 3 is filled into the concave hole 2 to fix the aluminum plate 3 and the pot body 1;

[0018] The above-mentioned mechanical pressing method: it can be made by a point pressing method through a press and a mold. Of course, the mold needs to be provided with convex posts matching the distribution of the concave holes 2;

[0019] In order to fix the aluminum plate 3 filled into the concave hole 2 and the pot body 1 firmly, the orifice of the concave hole 2 needs to shrink inward;

[0020] In order to facilitate the processing of the aluminum-iron meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com