Assembling-type thermal preserving and decorating composite board

A composite plate and assembly technology, which is applied in the direction of hydraulic material layered products, chemical instruments and methods, layered products, etc., can solve the problems of complex construction, prolong the construction period, delay the construction process, etc., and achieve effective utilization The effect of large area, improved seismic performance, and increased construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

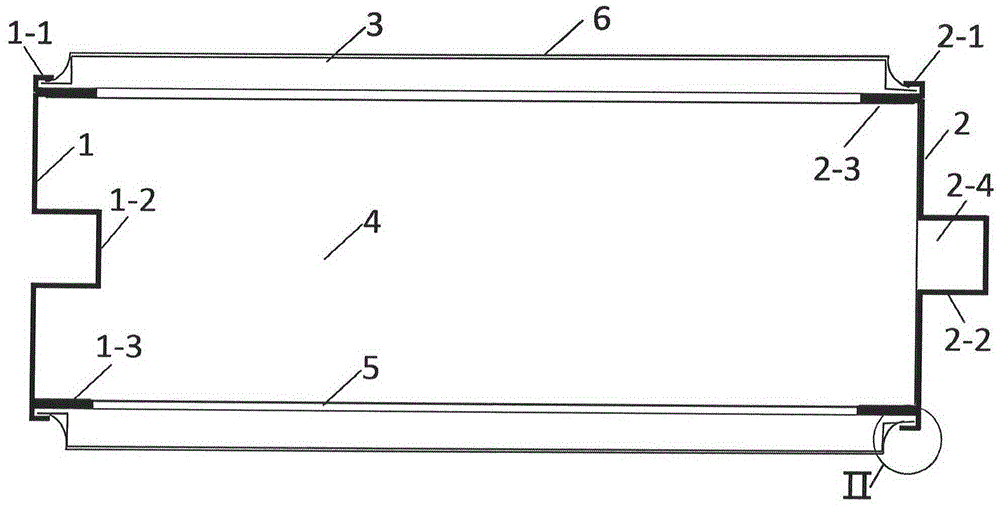

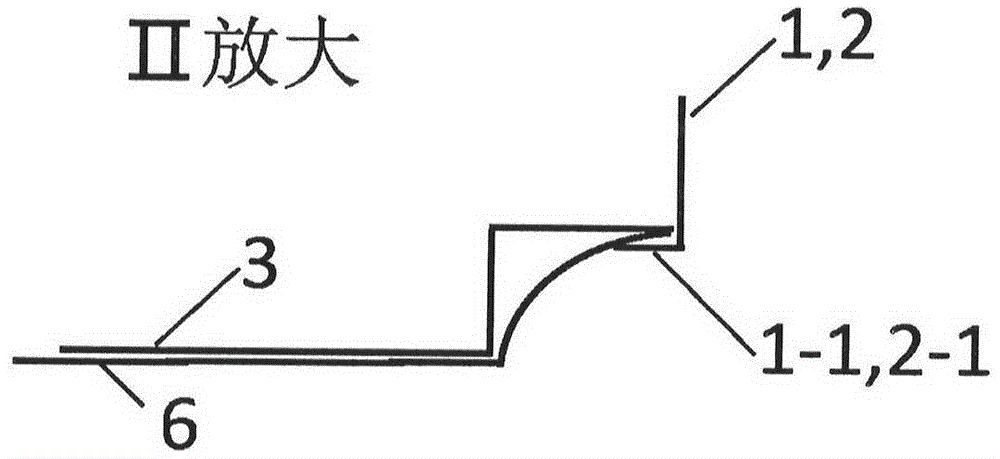

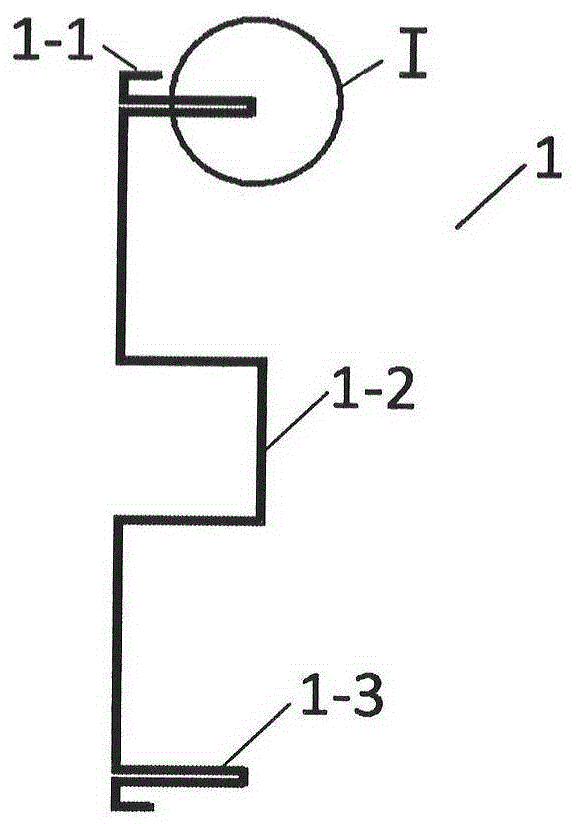

[0043] Such as figure 1 As shown, a fabricated thermal insulation decorative composite board includes a surface layer 6, an adhesive layer 5, a structural layer 3, a core layer 4 and edge strips with a certain strength and elasticity; the surface layer 6 is a decorative layer with a structure Layer 3 is a hard board such as cement board and has a stepped structure on the side. The core layer 4 is an insulation layer. The side strips include convex side strips 2 and concave side strips 1 matched with the convex side strips; The strip includes a structural layer rib 2-1, a convex portion 2-2, an edge strip fixing edge 2-3, and a convex cavity 2-4, and the concave edge strip includes a structural layer rib 1-1, a concave portion 1-2 The side strips are fixed to the sides 1-3, the surface layer 6, the structural layer 3, and the core layer 4 are combined into one body through the side strips 1, 2 and the adhesive layer 5. The stepped structure of the side of the structural layer 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com