A vertical cylinder rotary disc ice-cutting and snow-making equipment

A turntable snowmaking technology, which is applied in the field of snowmaking equipment and vertical cylinder turntable ice cutting and snowmaking equipment, can solve the problems of high maintenance cost, increase of natural snow, high technical content, etc., and achieve low maintenance cost, ice The effect of uniform particle size and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

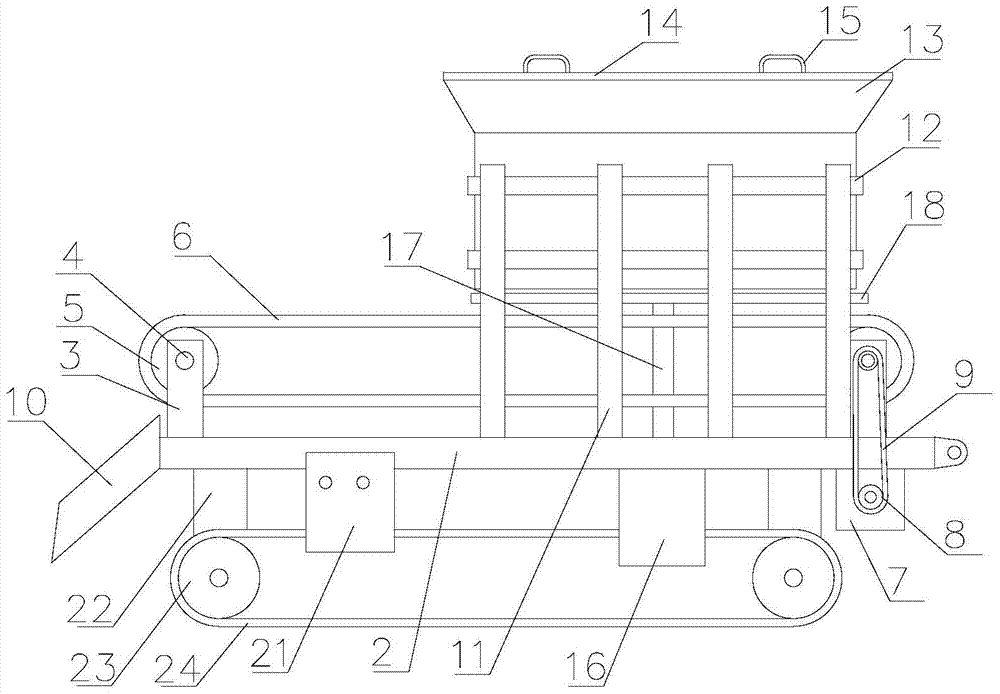

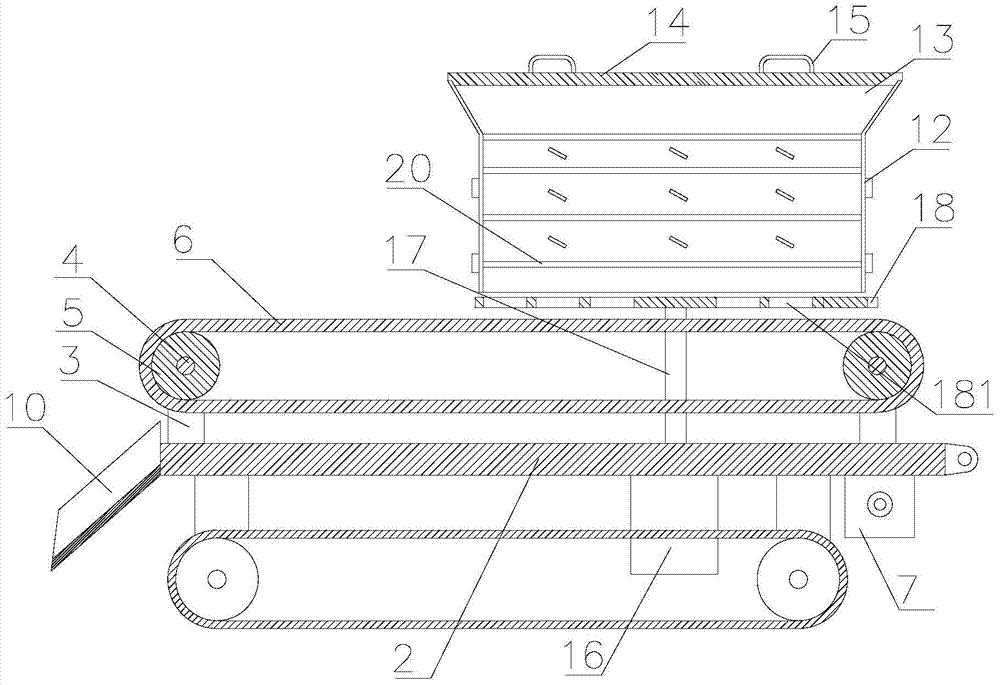

[0010] refer to figure 1 and figure 2 , a vertical cylinder turntable ice-cutting and snow-making equipment according to the present invention, comprising a wheel frame 22, a roller 23, a workbench 2, a conveyor belt support 3, a transmission shaft 4, a transmission roller 5, a conveyor belt 6, a transmission motor 7, a sprocket 8, Chain 9, barrel stand 11, barrel fixing ring 12, barrel 13, crushing motor 16, main shaft 17, anti-slip crawler belt 24, and crushing tray 18, and the left and right sides of the workbench 2 are respectively provided with conveyor belt brackets 3. A transmission shaft 4 is installed on the conveyor belt support 3, and a transmission roller 5 is set on the transmission shaft 4. The transmission rollers 5 are connected by a conveyor belt 6, and a transmission motor 7 is installed at the bottom of the workbench 2. A sprocket 8 is respectively installed on the transmission motor 7 and the transmission shaft 4, and the sprocket 8 is connected by a chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com